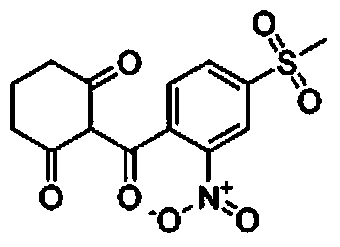

Method for electrochemical pretreatment on methyl sulcotrione pesticide wastewater

A technology for mesotrione and pesticide wastewater, which is applied in the field of environmental protection technology and electrochemistry, can solve problems that have not yet been seen, and achieve the effect of simple equipment, low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

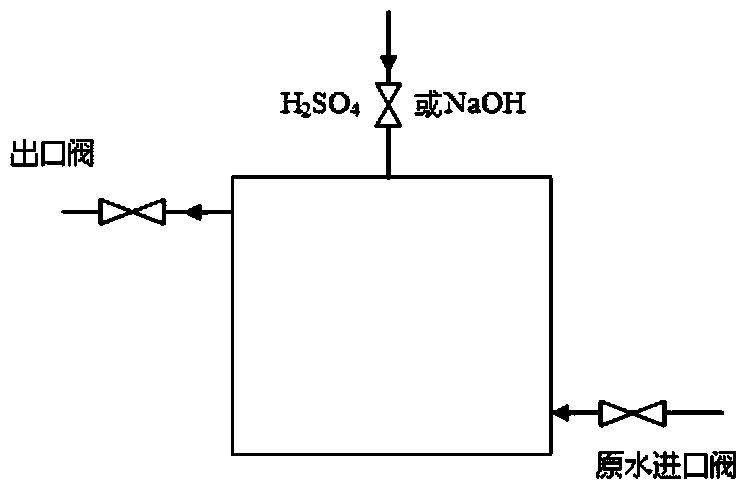

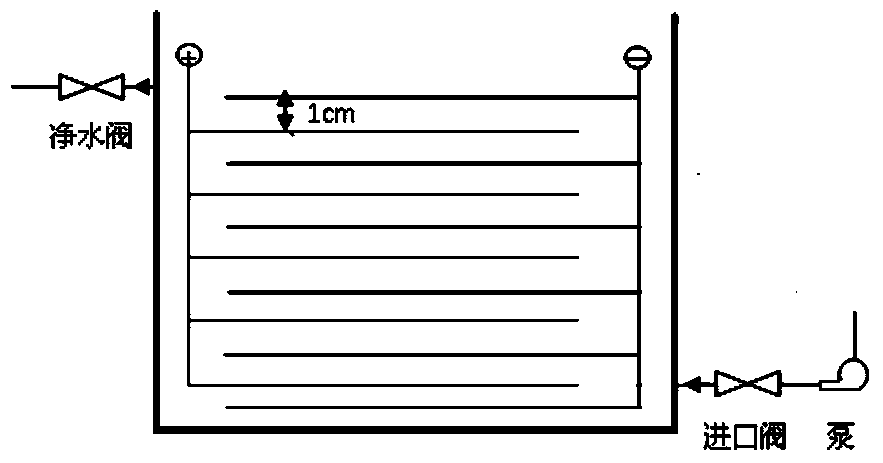

Method used

Image

Examples

Embodiment 1

[0028] Using an electrode with a molar ratio of Sn:Sb:Ru:Ce of 84:6:5:5 as the anode, adjust the pH value of the residual solution of mesotrione wastewater recovery to 3, and then pass the wastewater through the inlet at a flow rate of 0.05L / min The valve enters the electrolytic cell, and the constant current DC power supply is adjusted so that the current density is 30mA / cm 2 , the water quality before and after treatment is as follows:

[0029]

Embodiment 2

[0031] Using an electrode with a molar ratio of Sn:Sb:Ru:Ce of 88:6:3:3 as the anode, adjust the pH value of the residual liquid recovered from mesotrione wastewater to 3, and then pass the wastewater through the inlet at a flow rate of 0.2L / min The valve enters the electrolytic cell, and the constant current DC power supply is adjusted so that the current density is 40mA / cm 2 , the water quality before and after treatment is as follows:

[0032]

Embodiment 3

[0034] Using an electrode with a molar ratio of Sn:Sb:Ru:Ce of 85:6:4:5 as the anode, adjust the pH value of the residual liquid recovered from mesotrione wastewater to 4, and then pass the wastewater through the inlet at a flow rate of 0.1L / min The valve enters the electrolytic cell, and the constant current DC power supply is adjusted so that the current density is 40mA / cm 2 , the water quality before and after treatment is as follows:

[0035]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap