Method and device for water quenching of yellow phosphorus furnace slag

A yellow phosphorus slag and water quenching technology, which is applied in the chemical industry, can solve the problems of disorderly discharge of sewage and water vapor, poor site environment, and ineffective management, and achieve the effects of shortening water quenching time, standard collection, and automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for water quenching yellow phosphorus slag, the specific process is: lead the molten yellow phosphorus slag to the slag flushing ditch, then add high-pressure water to the slag flushing ditch for water quenching, wherein the flow velocity of the slag flushing water is 1.8 m / s, The amount of water added is 650 cubic meters per hour. At this time, 1.3 tons per minute of slag in the slag flushing ditch is brought into the buffer tower by water, and the water vapor generated during the water quenching process is collected in the buffer tower. Finally, the material enters the dehydrator for Separation, the separated water is used for the subsequent water quenching process of the slag after precipitation, the separated slag is stored and recycled, and the slag obtained from the water separated from the dehydrator is also stored and recycled.

Embodiment 2

[0023] A method for water-quenching yellow phosphorus slag, the specific process is: lead the molten yellow phosphorus slag to the slag-washing ditch, then add high-pressure water to the slag-washing ditch for water quenching, wherein the flow velocity of the slag-washing water is 2.8 m / s, The amount of water added is 770 cubic meters per hour, and 1.53 tons per minute of slag in the slag flushing ditch is brought into the buffer tower by water, and the water vapor generated during the water quenching process is collected in the buffer tower, and finally the material enters the dehydrator for separation. After the water is precipitated, it is used for the subsequent water quenching process of the slag. The separated slag is stored and recycled, and the slag obtained from the water precipitation separated from the dehydrator is also stored and recycled.

Embodiment 3

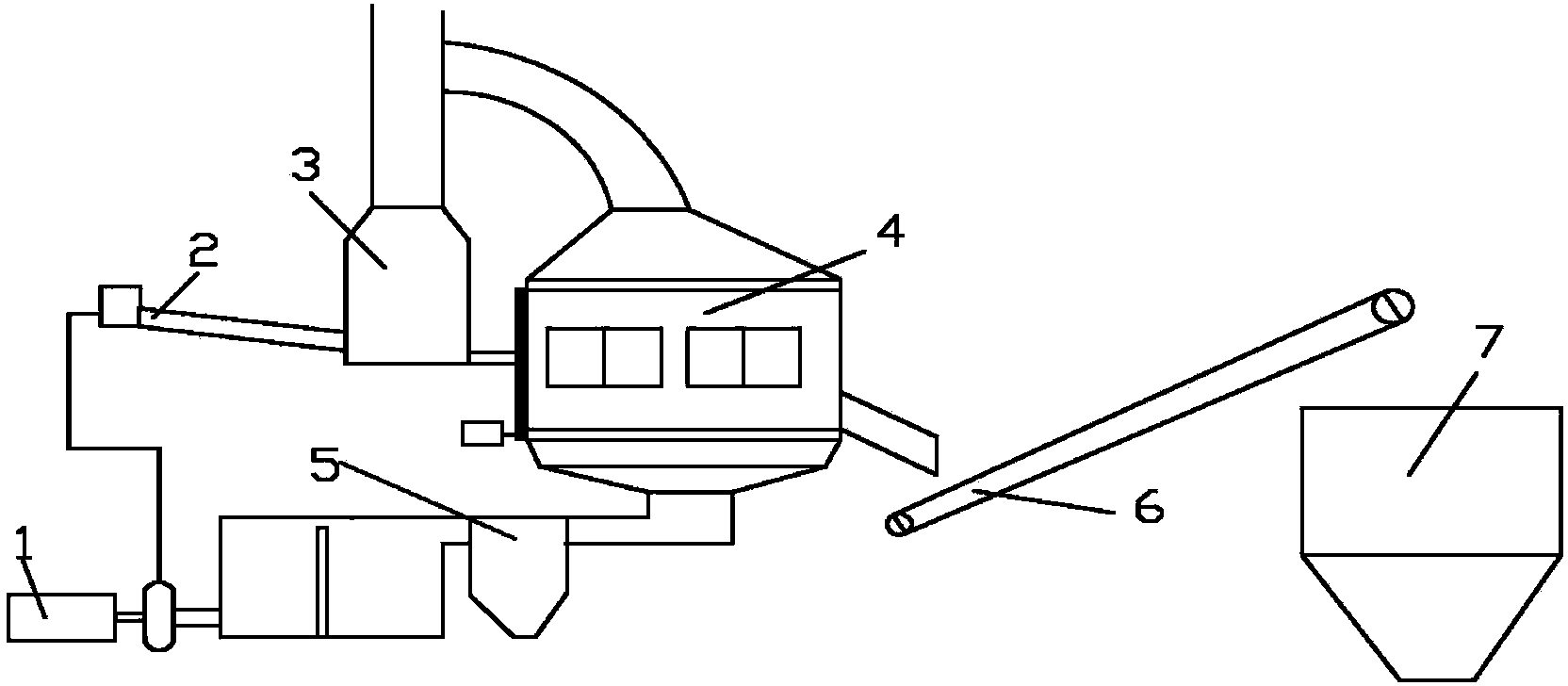

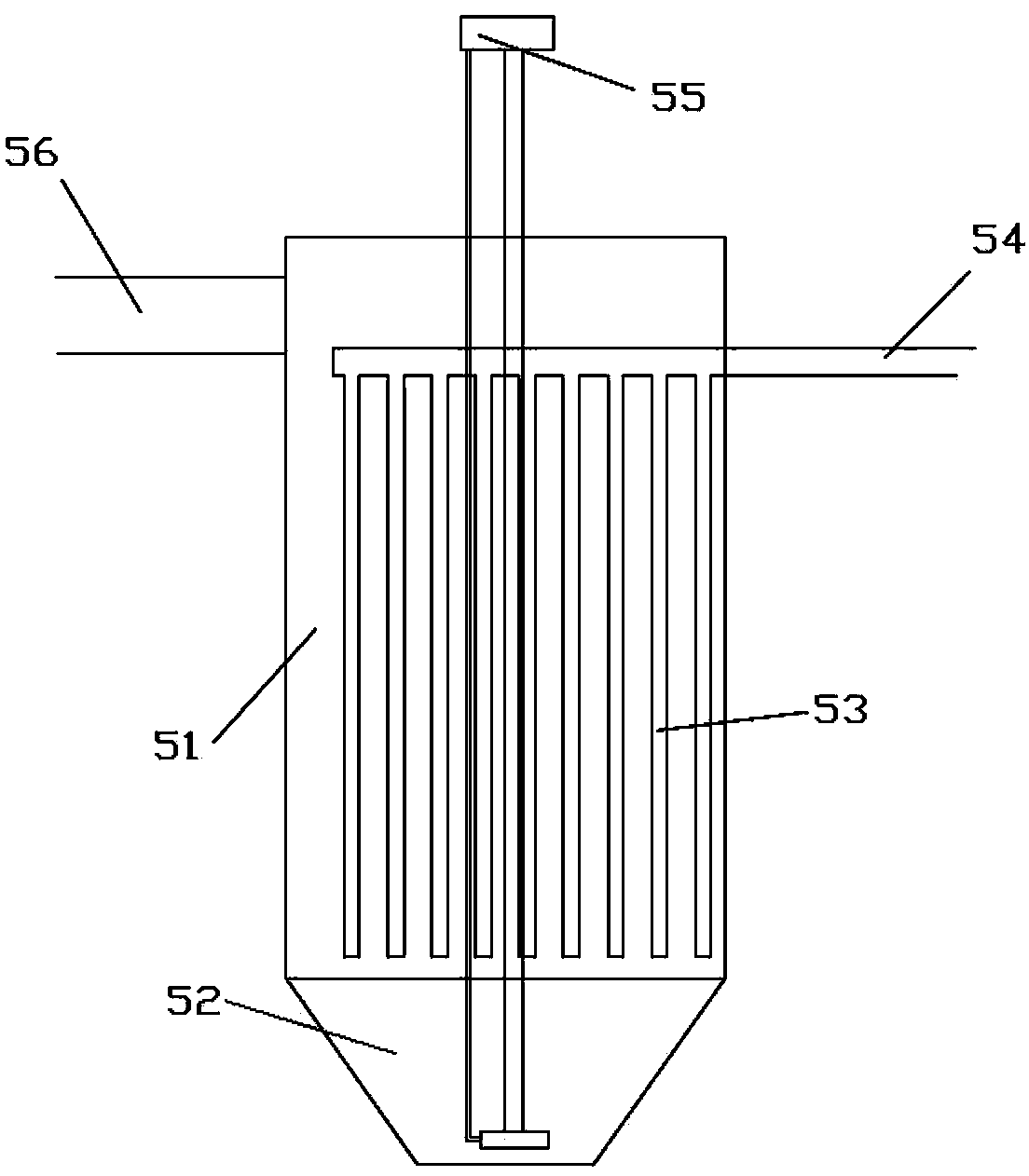

[0025] A device for water-quenching yellow phosphorus slag, comprising a slag flushing ditch 2, a buffer tower 3 and a dehydrator 4 connected in sequence, wherein the dehydrator 4 is provided with a water outlet and a slag outlet, and the water outlet passes through a circulation pool 5 and a circulation pump 1 connected to the slag flushing ditch; the slag outlet of the dehydrator 4 is connected to the slag storage bin 7 through the belt 6; the circulation pool 5 includes a sedimentation tank, and the sedimentation tank is a cylinder 51 with a cylindrical structure, and the bottom of the cylinder is connected There is an inverted conical sedimentation bin 52, a water inlet 56 is provided above the side wall of the cylinder body 51, and a plurality of forced diversion beam tubes 53 are arranged in the cylinder body, and the top of the forced diversion beam tube is connected to the water outlet 54 through a pipeline, and the water outlet The side wall located above the cylinder ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap