Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

15 results about "Aniline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aniline is an organic compound with the formula C₆H₅NH₂. Consisting of a phenyl group attached to an amino group, aniline is the simplest aromatic amine. Its main use is in the manufacture of precursors to polyurethane and other industrial chemicals. Like most volatile amines, it has the odor of rotten fish. It ignites readily, burning with a smoky flame characteristic of aromatic compounds.

Method for preparing liquid fluorescent brightener composition of diphenylvinyl triazine compounds

ActiveCN102477227AImprove performanceWith strong fluorescenceStyryl dyesLuminescent/fluorescent substance additionRoom temperatureAniline

The present invention relates to a production process of a chemical additive special for papermaking, in particular to a method for preparing a liquid fluorescent brightener composition of diphenylvinyl triazine compounds. The invention mainly solves the problems of low fluorescence intensity and low brightness of a single-component liquid fluorescent brightener. The method adopts cyanuric chloride, 4,4'-diamino-2,2'-stilbenedisulfonic acid (DSD acid), aniline, monoethanolamine and 1-R1-2-R2-acrylamide as raw material, and employs four-step reaction. The inventive liquid fluorescent brightener composition has convenient usage, good acid resistance, and good storage stability at a room temperature, and is suitable for continuous adding and metering during automatic production.

Owner:JIANGSU JINGUANG CHEM TECH CO LTD

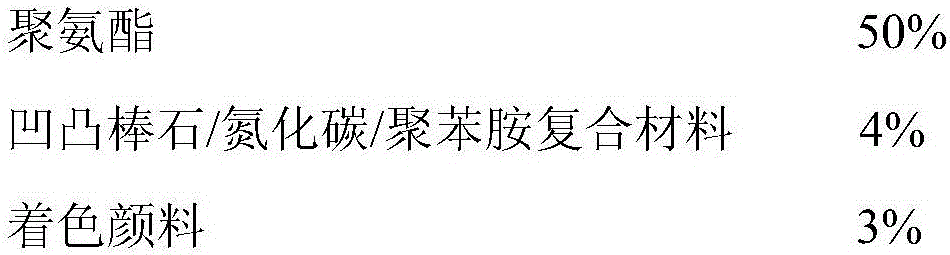

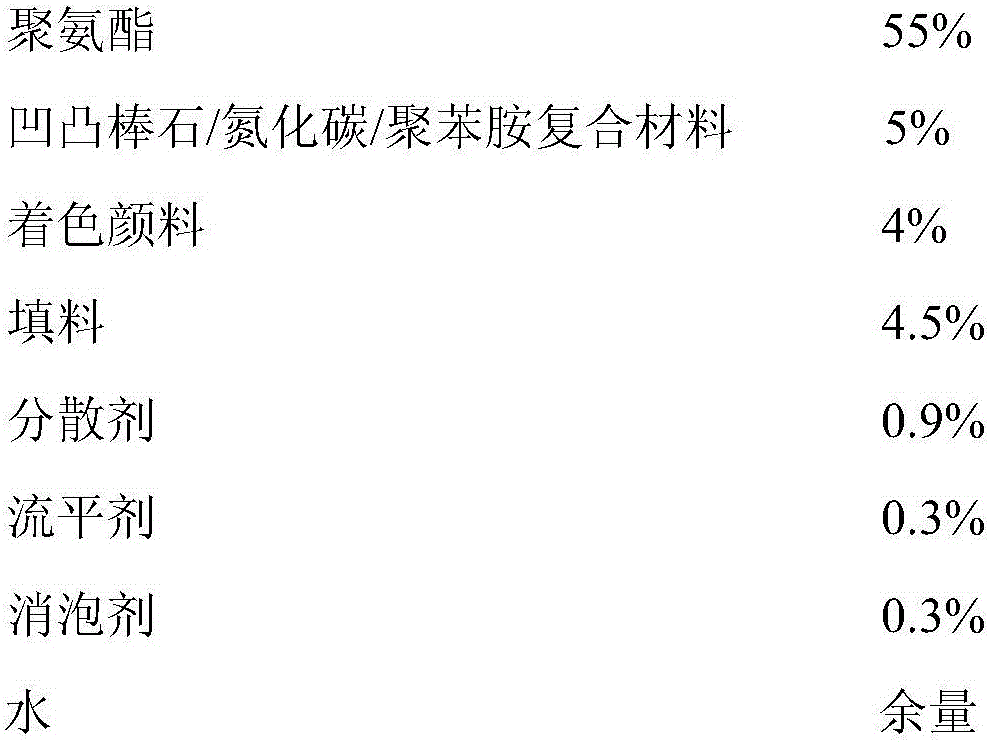

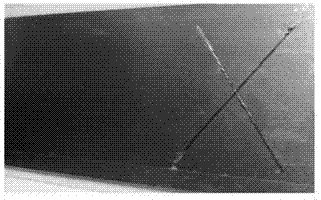

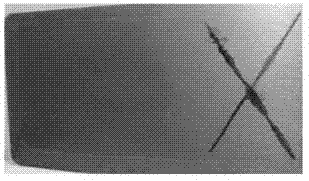

Preparation method of attapulgite-carbon nitride-polyaniline composite material and application thereof in anticorrosive paint

InactiveCN105754092AAvoid reunionReduce manufacturing costAnti-corrosive paintsPolyurea/polyurethane coatingsCarbon nitrideGraphite

Owner:CHANGZHOU UNIV

Anticorrosive additive with polyaniline covering gas-phase nano-silica, and preparation method and application thereof

Owner:TONGJI UNIV

HDPE (high-density polyethylene) antibacterial plastic and preparation method thereof

The invention discloses HDPE (high-density polyethylene) antibacterial plastic, which is mainly prepared from the following raw materials in parts by weight: 100 parts of HDPE, 4-8 parts of an antibacterial agent, 2-3 parts of ethylene bis-stearamide, 3-5 parts of a compatilizer and 1-2 parts of a plasticizer. The HDPE antibacterial plastic adopts 2-methoxy-N-acetoacetyl aniline and lithium carbonate as the antibacterial agent, and through reasonable compatibility, the best pathogenic microorganism killing effect and growth inhibiting effect can be achieved; a ethylene-propylene copolymer is used as the compatilizer, and after the compatilizer is combined with the HDPE, the mechanical strength of the HDPE can be further increased; the flexibility and easy-processing performance of the HDPEare improved by adding acetyl tributyl citrate; the antibacterial performance of the HDPE is further improved by adding chitosan.

Owner:NANTONG YIXUAN IND DESIGN CO LTD

Composite electrode material and preparation method thereof, and super capacitor

PendingCN110970226ALarge specific surface areaHigh specific capacitanceHybrid capacitor electrodesElectrolytic agentCapacitance

Owner:EAST CHINA UNIV OF SCI & TECH

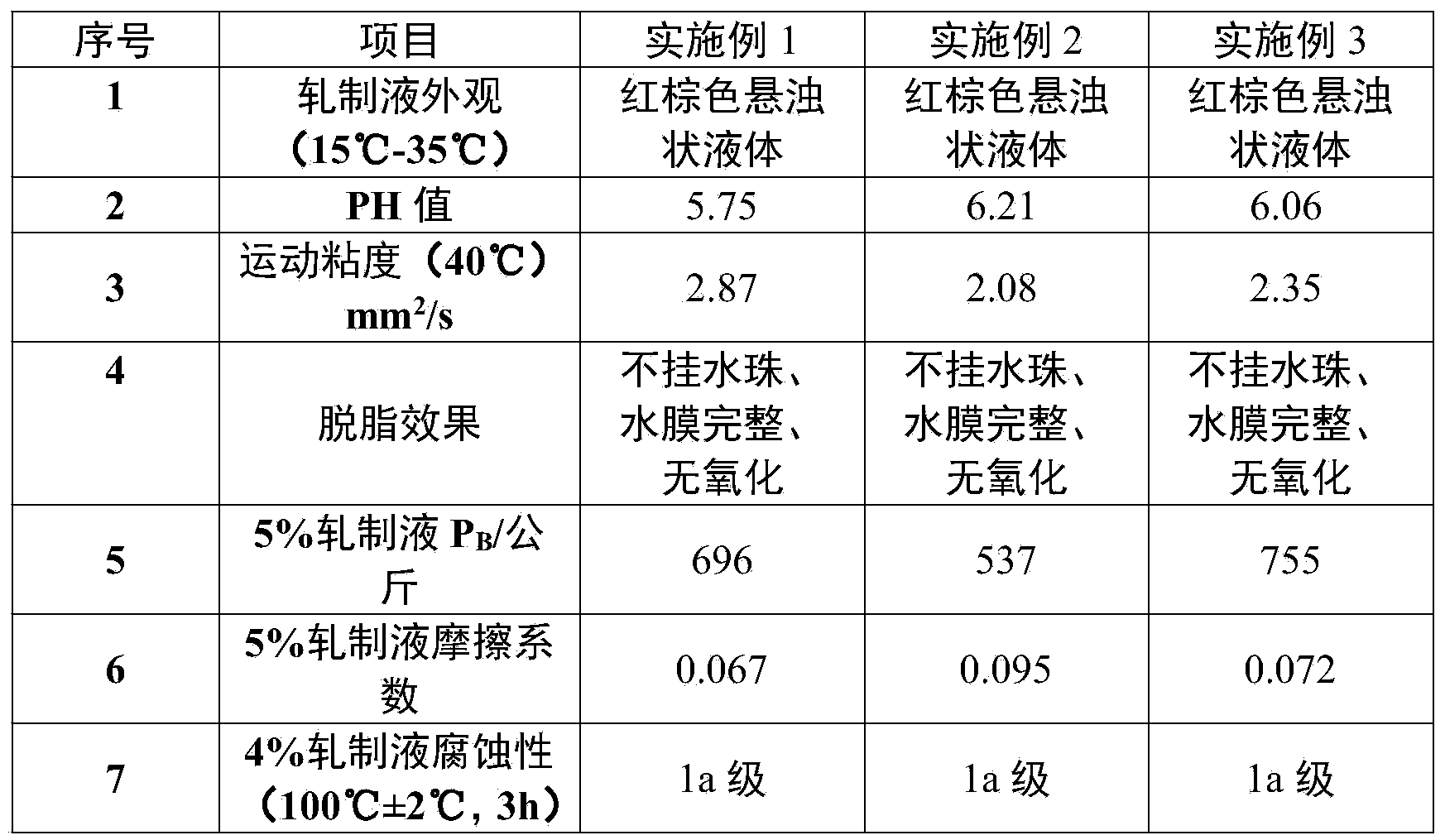

Functional rolling liquid of water-based nano Cu and preparation method of functional rolling liquid

Owner:UNIV OF SCI & TECH BEIJING

Water-based acid pickling corrosion inhibition passivator for stainless steel

InactiveCN107326352ANon-toxicEnvironmentally friendlyMetallic material coating processesWater basedPhosphate

The invention discloses a water-based pickling corrosion inhibitor and passivator for stainless steel, which comprises the following substances in parts by weight: 2-3 parts of phenylalanine, 1-5 parts of acetic acid, 1-2 parts of lactic acid, 1-2 parts of dipotassium hydrogen phosphate, Potassium dihydrogen phosphate 0.5~1 part, phosphoric acid 1~2 part, thiourea 0.1~0.3 part, aniline 1~1.5 part, ethanol 1~2 part, DTPMPA 1~2 part, calcium chromate 0.2~0.5 part, potassium nitrate 1~2 parts, 0.1~0.5 parts of EDTA, 3~8 parts of water. The water-based pickling corrosion inhibitor passivator for stainless steel has the advantages of non-toxicity, environmental protection, good passivation effect and the like.

Owner:SUZHOU JILI STAINLESS STEEL PROD

Wear-resistant flame-retardant TPU material and preparation method thereof

The invention relates to the technical field of TPU materials, and particularly discloses a wear-resistant flame-retardant TPU material and a preparation method thereof. The TPU material is prepared from the following raw materials in parts by weight: 60 to 100 parts of polyurethane, 15 to 30 parts of epoxy resin, 3 to 10 parts of di-o-chlorodiphenylamine methane, 20 to 50 parts of polyethylene, 10 to 28 parts of modified calcium sulfate dihydrate whisker, 10 to 28 parts of composite flame retardant and 2 to 6 parts of silicone oil. The preparation method comprises the following steps: uniformly mixing the silicone oil and the modified calcium sulfate dihydrate whisker to obtain a mixture A; uniformly mixing polyurethane, epoxy resin, di-o-chlorodiphenylamine methane and polyethylene to obtain a mixture B; then adding the composite flame retardant into the mixture B, and uniformly stirring to obtain a mixture C; finally, uniformly mixing the mixture A and the mixture C to prepare the wear-resistant and flame-retardant TPU material. The wear-resistant flame-retardant TPU material disclosed by the invention has the advantages of high wear resistance and high flame retardance.

Owner:RONGWEIDA OPTOELECTRONICS (DONGGUAN) CO LTD

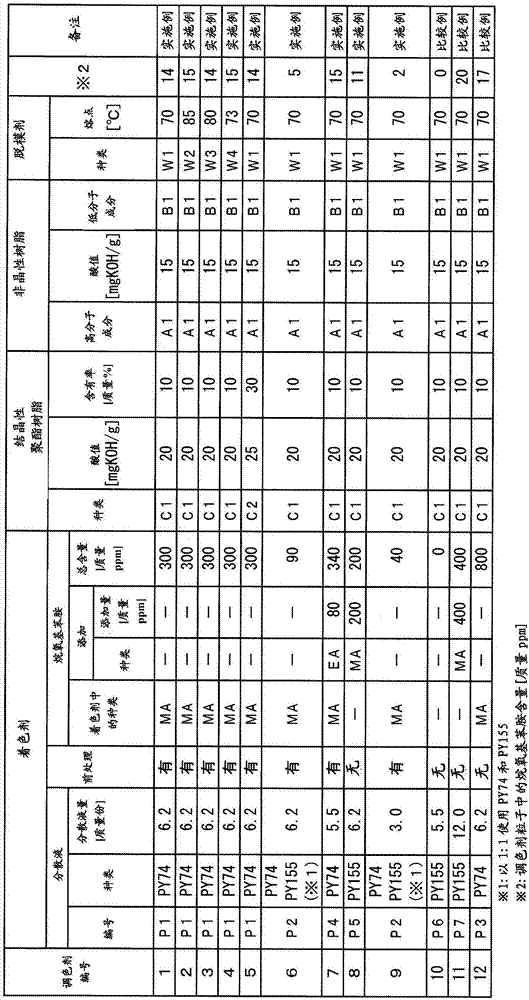

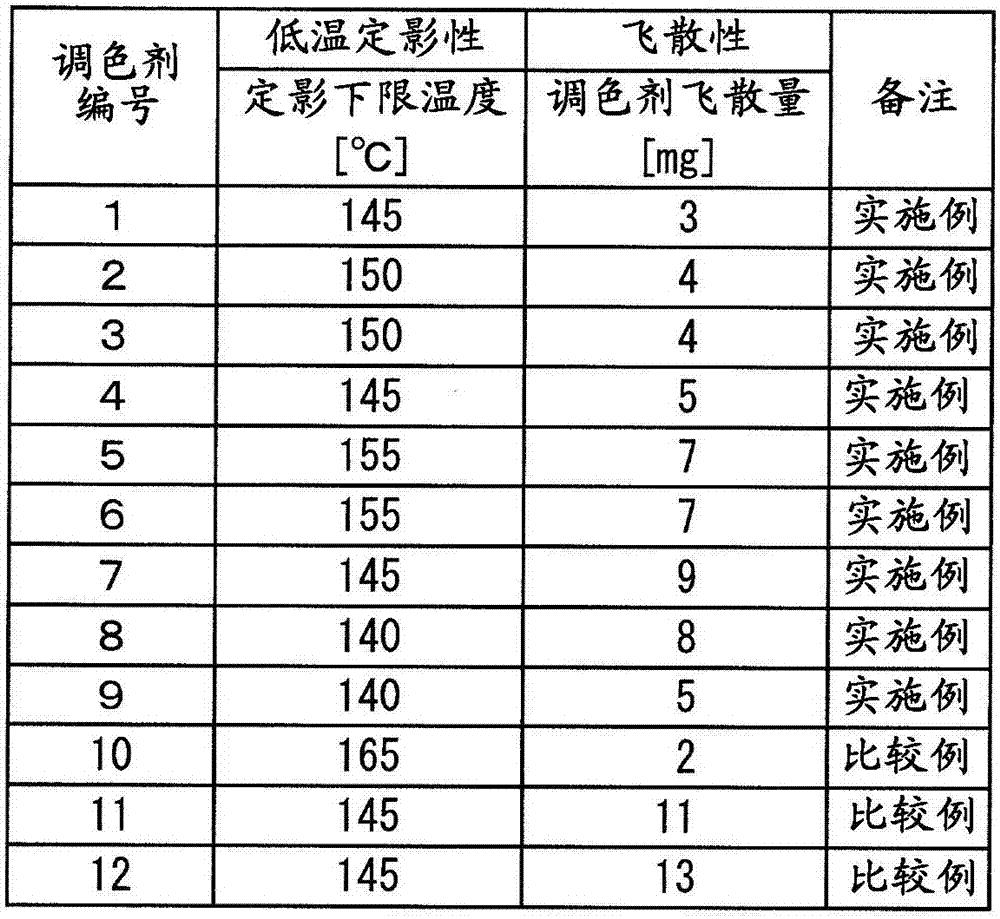

Electrostatic image developing toner

InactiveCN107450291AExcellent low temperature fixabilityReduce flyingDevelopersEngineeringPolyester resin

Owner:KONICA MINOLTA INC

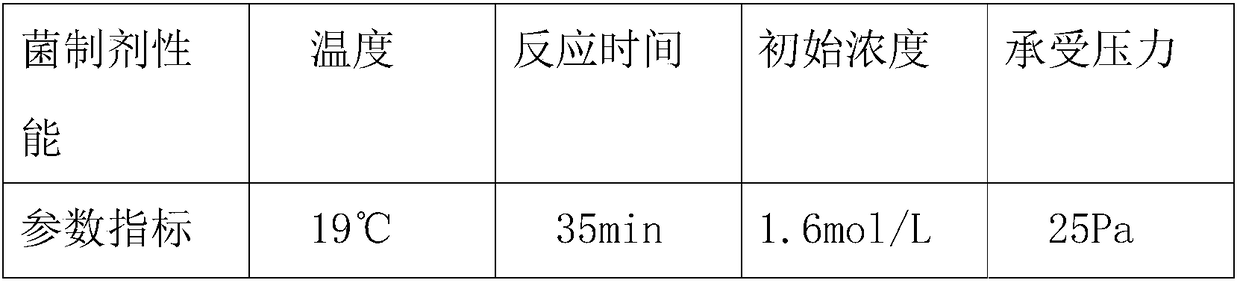

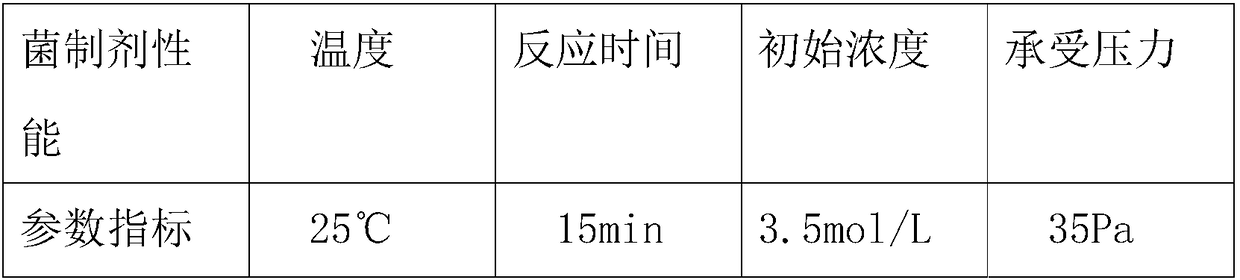

Efficient phenylamine degradable bacterial preparation and preparation method thereof

Owner:FOSHAN KEFENG CULTURE COMM CO LTD

Method using carbon nitrogen doped zinc-titanium nano particles to treat aromatic amine pharmaceutical wastewater

ActiveCN108654670AOvercome the disadvantage of not being able to use in the visible light regionHigh catalytic efficiencyWater/sewage treatment by irradiationWater contaminantsNanoparticleCarbon nitride

The invention belongs to the technical field of water pollution control and particularly relates to a method using carbon nitrogen doped zinc-titanium nano particles to treat aromatic amine pharmaceutical wastewater. Melamine serving as the carbon source and the nitrogen source is subjected to high-temperature calcination to form graphite-phase carbon nitride, the carbon nitride is loaded with nano zinc oxide to form zinc oxide loaded graphite-phase carbon nitride nano particles (ZnO@g-C3N4), and using a sol-gel method to prepare the carbon nitrogen doped zinc-titanium nano particles with optical catalytic performance. The prepared carbon nitrogen doped zinc-titanium nano particles can well degrade 2,5-bis(trifluoromethyl)aniline under a weak acid condition, can be used for degrading otheraromatic amine wastewater and is promising in industrial application prospect.

Owner:GUANGDONG ANNA TESTING TECH CO LTD

Fuzz conducting garment with camera shooting function

InactiveCN106174748ASuitable for meeting conductivity needsMeet conductivity needsProtective garmentSpecial outerwear garmentsVideo recordEngineering

Owner:JIANGYIN BETTER TEXTILE

Method for strengthening rhodococcus to degrade aniline by utilizing environmental stress

ActiveCN111908620APromote degradationImprove degradation rateTreatment using aerobic processesWater contaminantsGroundwater remediationAniline

The invention discloses a method for strengthening Rhodococcus sp. to degrade aniline by utilizing environmental stress, and belongs to the field of biological strengthening treatment of environmentalpollution. According to the method disclosed by the invention, the Rhodococcus sp. is pretreated by using phenol, NaCl and low temperature (15-25 DEG C) mainly according to the principle that the response of the Rhodococcus sp. to phenol, NaCl, aniline and low temperature stress is the same or similar, so that the degradation capacity of the Rhodococcus sp. to aniline under abiotic environmentalstress is improved. The method provided by the invention has a remarkable effect of improving the aniline treatment capacity, is simple and convenient in process, low in cost and free of secondary pollution, and can be widely applied to industrial wastewater treatment, soil remediation, underground water remediation and other scenes.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

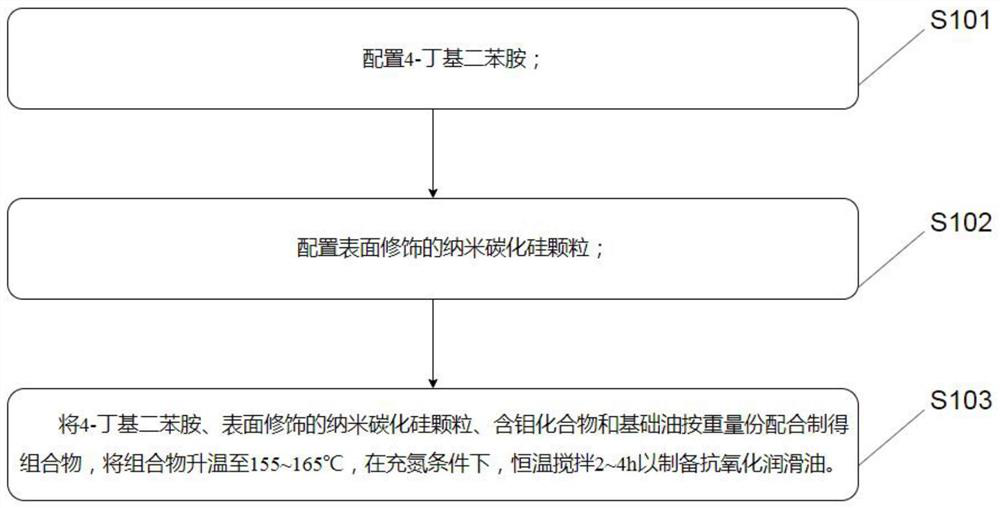

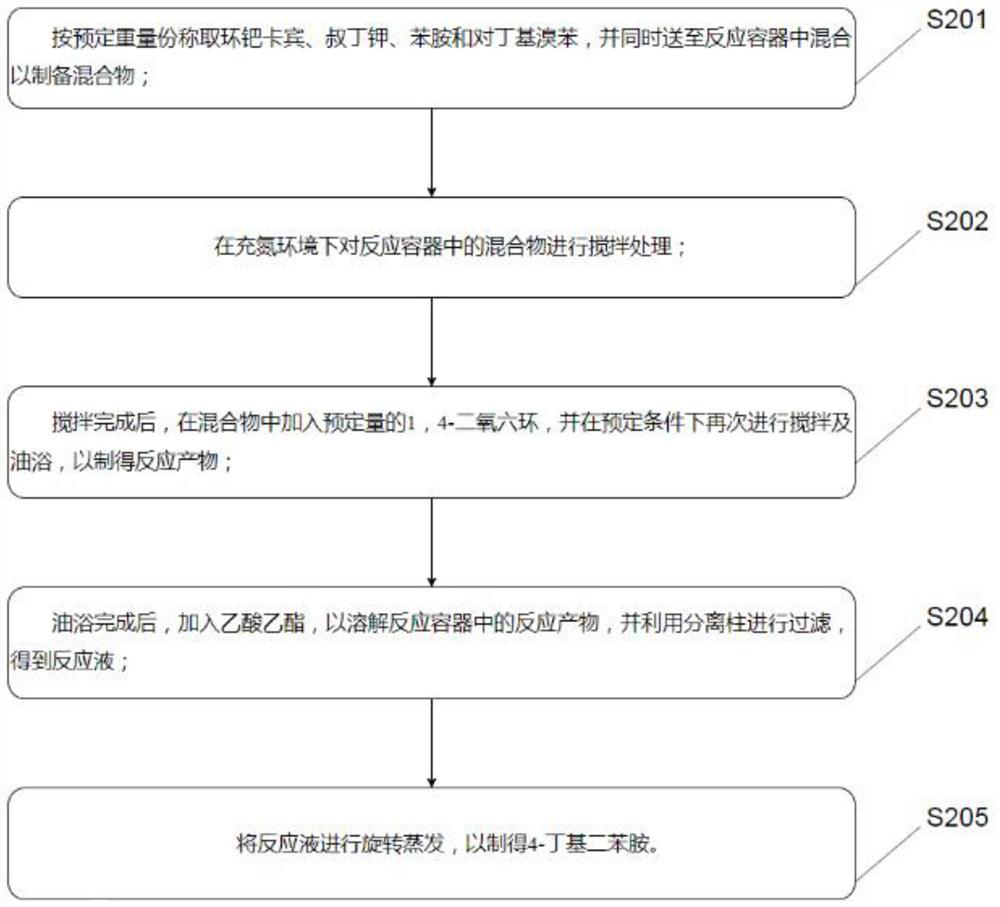

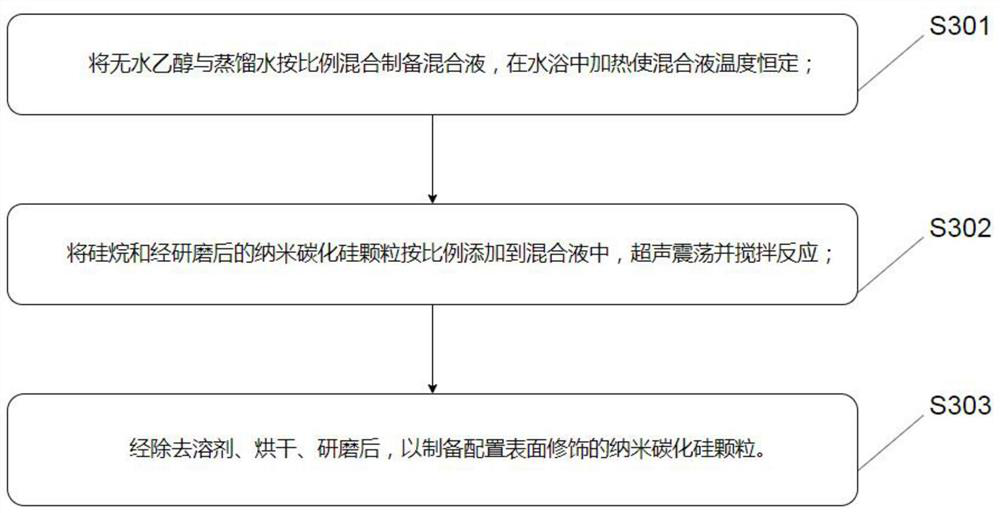

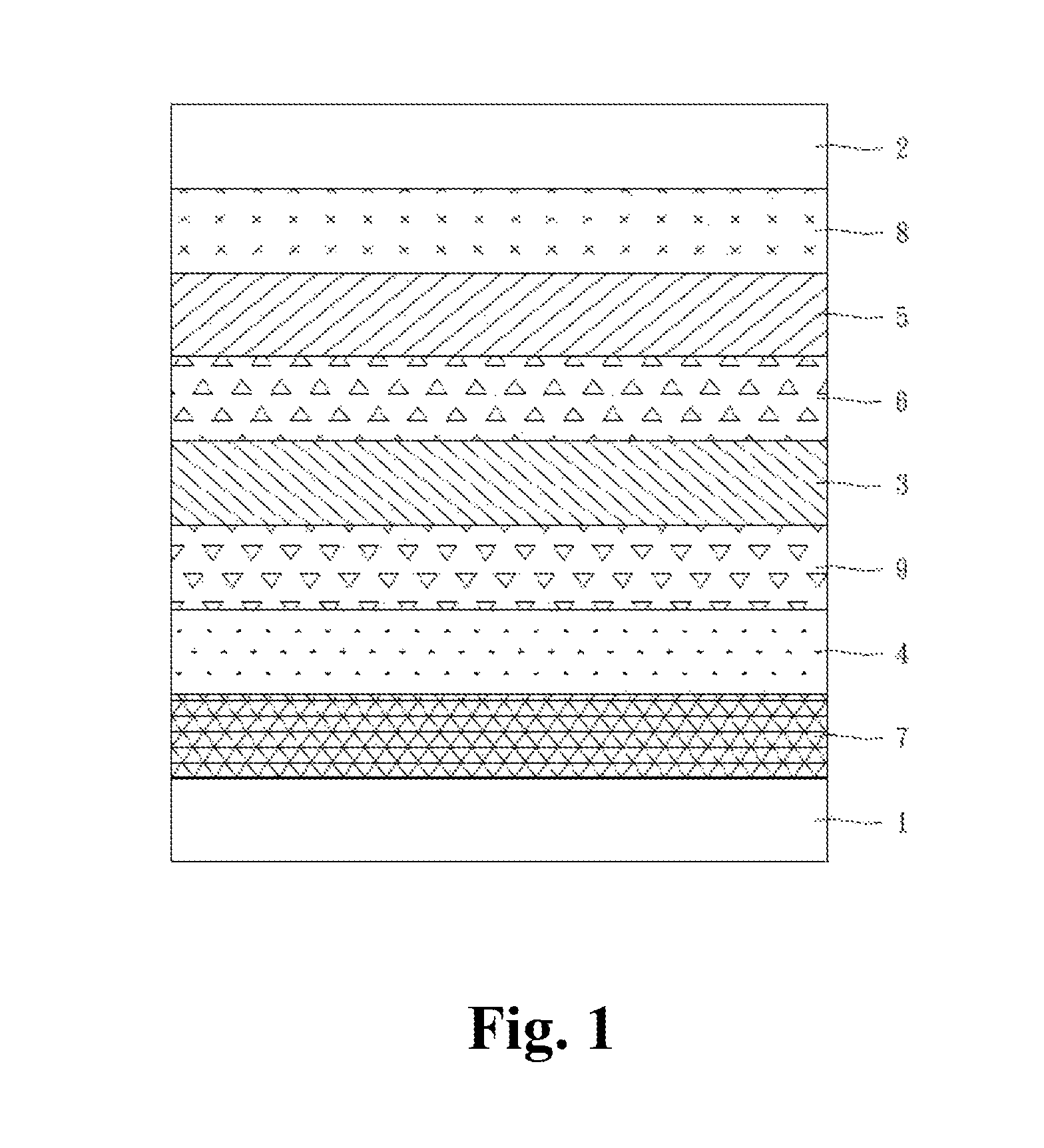

Anti-oxidation lubricating oil and preparation method thereof

Owner:力能石油科技有限公司

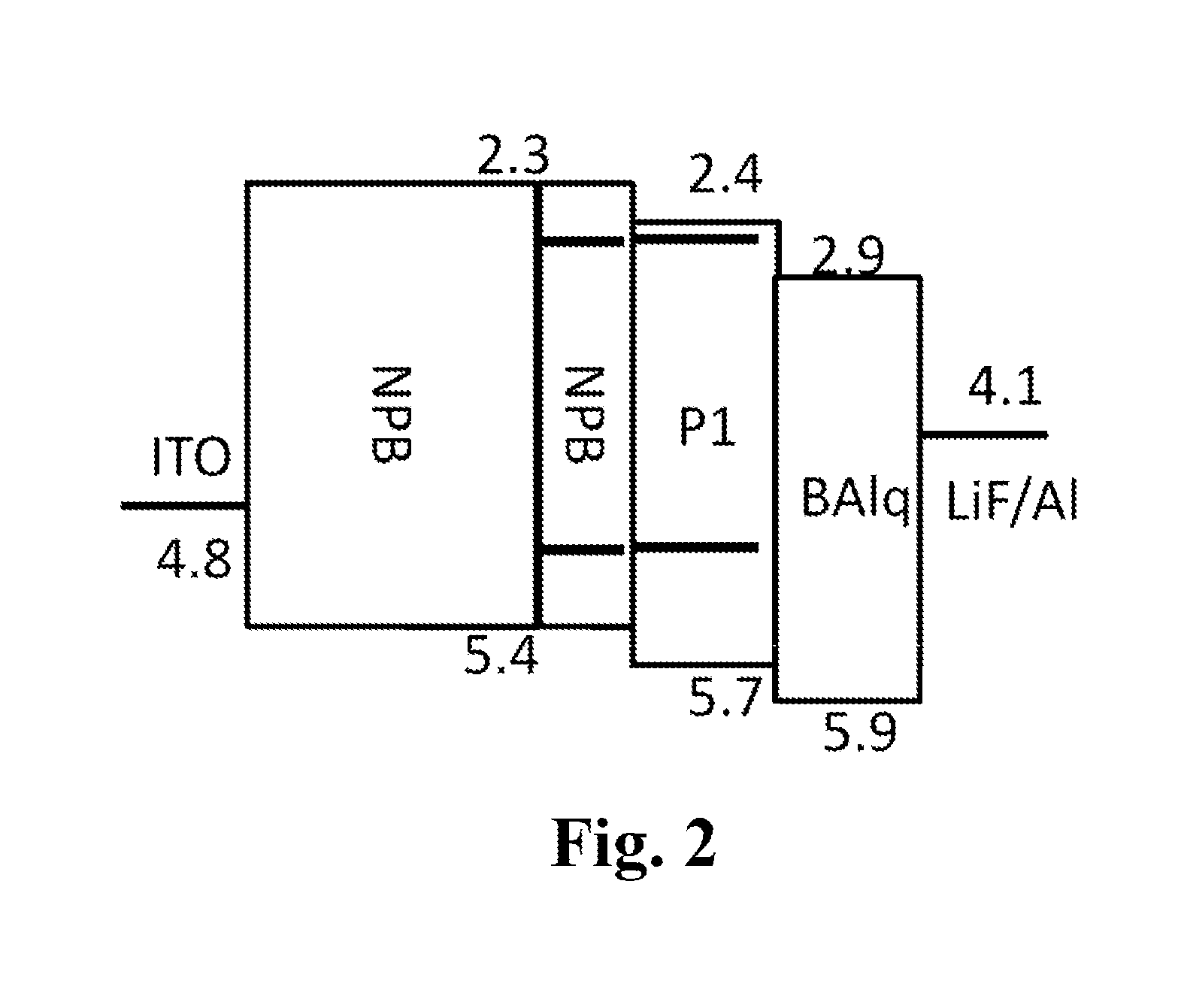

Asymmetric styrene derivatives having carbazole and aniline and organic light emitting diode using the same

Owner:NATIONAL TSING HUA UNIVERSITY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap