Sulfonated copolymer synthetized by 1,3-2(3-diisobutyl sodium-4-fluroben-formoyl) and its method

A fluorobenzoyl and sodium sulfonate-based technology, applied in the field of polymer chemistry, can solve problems such as low proton conductivity, hindering commercialization process, and high methanol permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

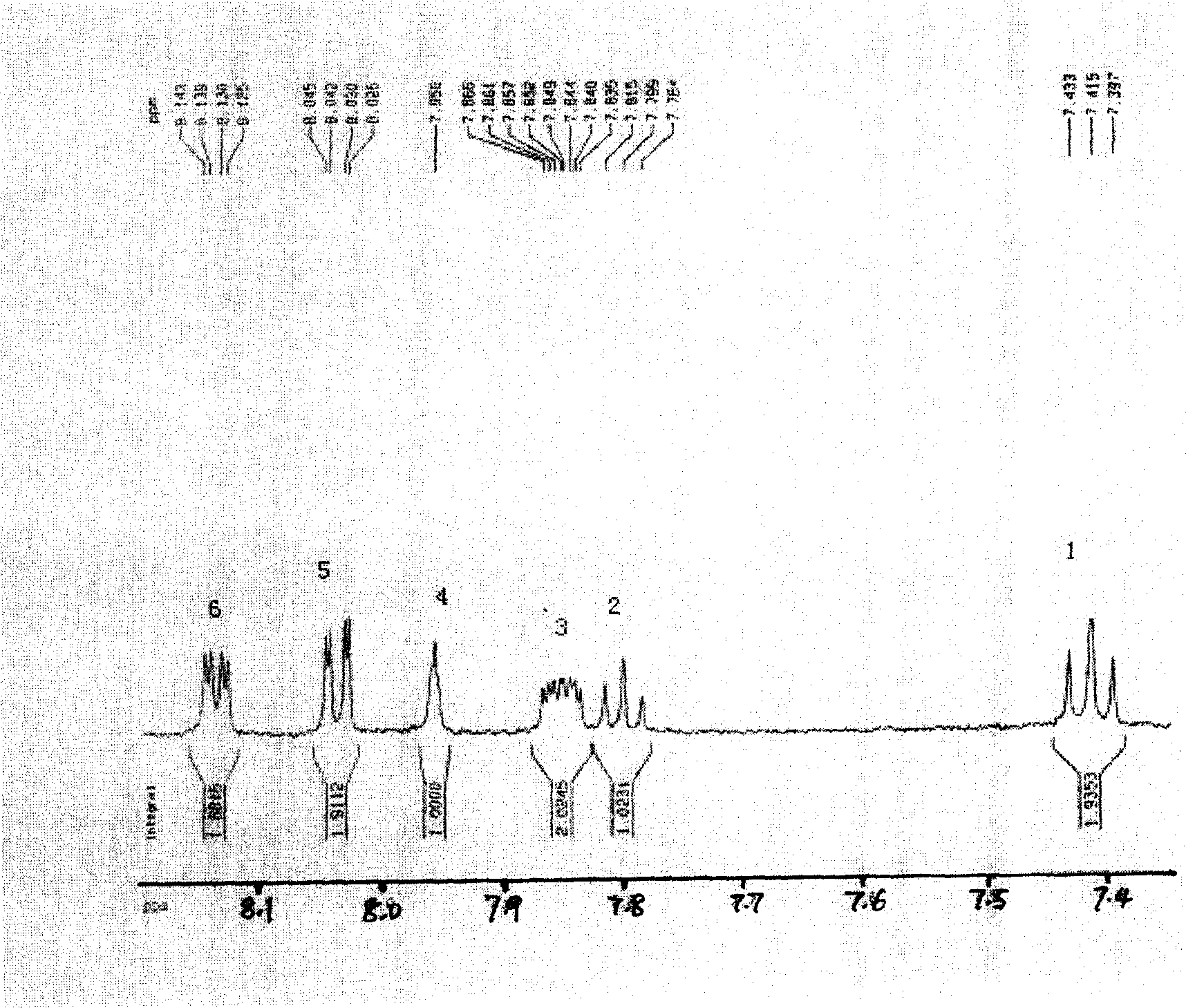

[0026] Example 1: Synthesis of 1,3-bis(3-sodium sulfonate-4-fluorobenzoyl)benzene:

[0027] A mixture of 32.2g (0.1mol) 1,3-bis(4-fluorobenzoyl)benzene and 40ml oleum (about 0.4mmol) was heated to 110°C for 6h, and the heating was stopped. When the temperature of the mixture dropped below 50°C, the mixture was poured into 500ml of ice water. Then add sodium hydroxide until the solution is neutral, add sodium chloride (150 g) for salting out after cooling down to room temperature, filter with suction, dry at 80°C for 12 hours, and use a mixed solution of methanol (ethanol is also available) and water (volume 5:1-7:1) recrystallization to obtain pure 1,3-bis(3-sodiumsulfonate-4-fluorobenzoyl)benzene.

Embodiment 2

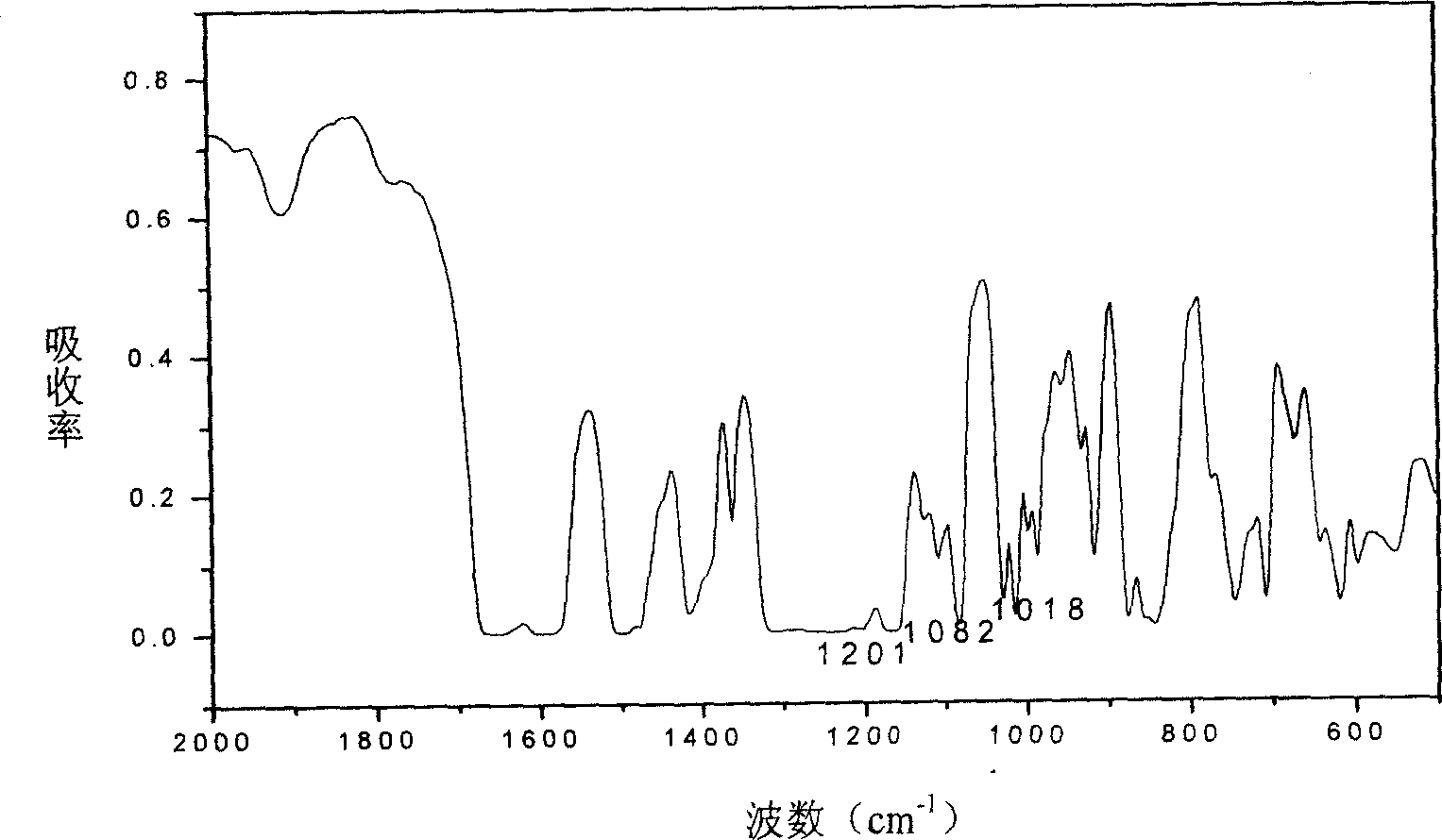

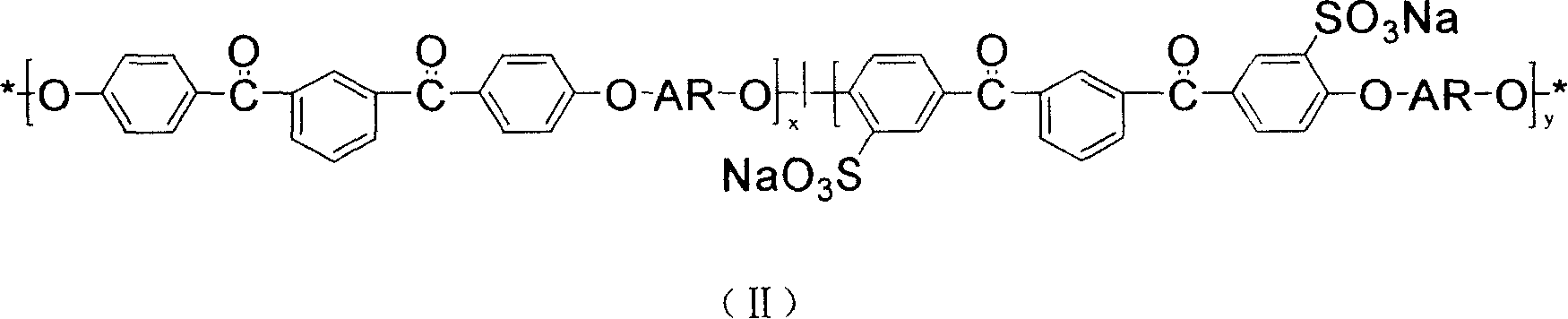

[0029] For the synthesis of copolymers, m mol 1,3-bis(3-sulfonate sodium-4-fluorobenzoyl)benzene, k mol 1,3-bis(4-fluorobenzoyl)benzene, m+k mol of bisphenol A and m+k mol of anhydrous potassium carbonate were added to a three-necked flask equipped with mechanical stirring and a thermometer. Nitrogen protection, DMSO (NMP, TMS, DMAC can also be used) as a solvent (solid content: 20%), toluene as a water-carrying agent, carry water at 140 ° C for 4 hours, then distill the toluene and heat up to 180 ° C for 6 hours. Pour the mixture into water or acetone, pulverize and filter with a pulverizer, boil and filter the solid directly with acetone boiling method, repeat 5 to 6 times, then boil and filter with distilled water, repeat 5 to 6 times, and dry in an oven dry to obtain a copolymer. (m / k=1 / 9, 2 / 8, 3 / 7, 4 / 6, 5 / 5, 6 / 4...)

[0030] Numbering

[0031] Note: m is the content of 1,3-bis(3-sulfonate-4-fluorobenzoyl)benzene, k is the content of 3,3'-bis(4-fluo

Embodiment 3

[0033] m mol 1,3-bis(3-sulfonate-4-fluorobenzoyl)benzene, k mol 1,3-bis(4-fluorobenzoyl)benzene, m+k mol tetramethyl Add biphenol and m+k mol of anhydrous potassium carbonate into a three-necked flask equipped with mechanical stirring and a thermometer. Nitrogen protection, DMSO (NMP, TMS, DMAC can also be used) as a solvent (solid content: 20%), toluene as a water-carrying agent, carry water at 140 ° C for 4 hours, then distill the toluene and heat up to 180 ° C for 6 hours. Pour the mixture into water, pulverize and filter with a pulverizer, boil and filter the solid directly with acetone boiling method, repeat 5 to 6 times, then boil and filter with distilled water, repeat 5 to 6 times, and dry in an oven to obtain copolymer. (m / k=1 / 9, 2 / 8, 3 / 7, 4 / 6, 5 / 5, 6 / 4...)

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap