Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17 results about "Pressure difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressure difference is basically an imbalance in the forces acting on a fluid. And classical mechanics tells us that an unbalanced force will result in motion. Thus a pressure difference causes fluid motion from higher to lower pressure.

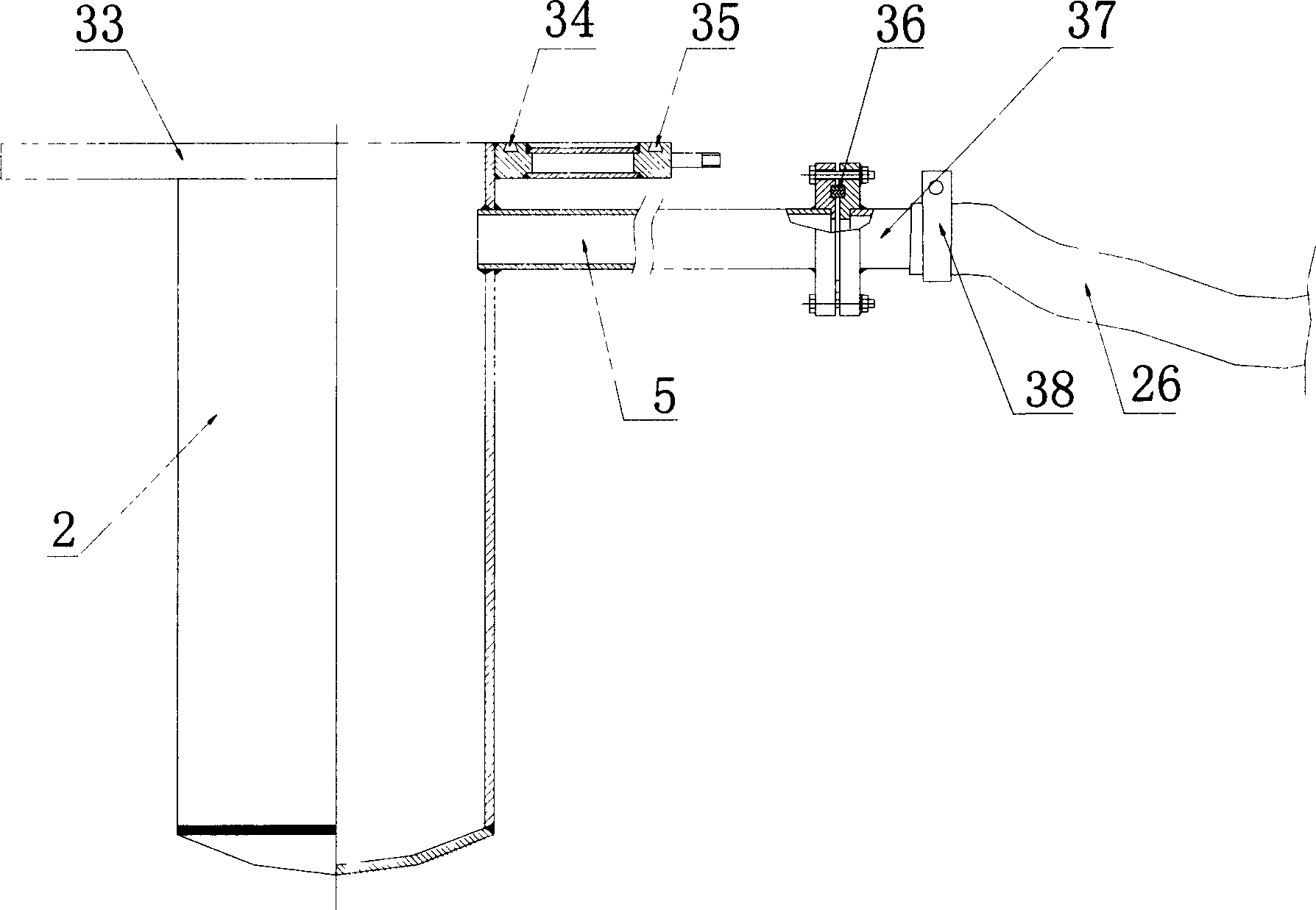

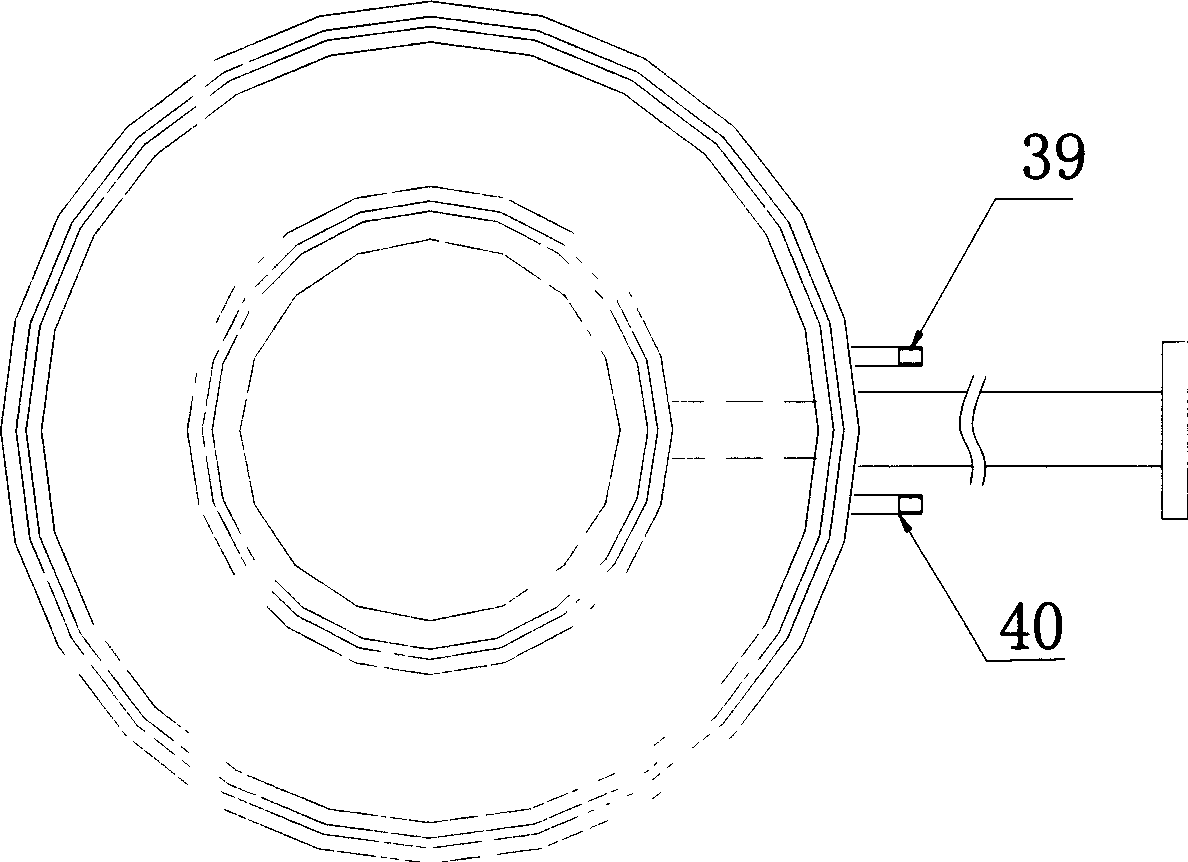

Pressure adjustable casting method and crucible therefor

InactiveCN1613578AImprove the exhaust effectReduce turbulenceCrucible furnacesCrucibleLiquid metal

Owner:BEIJING JIAOTONG UNIV

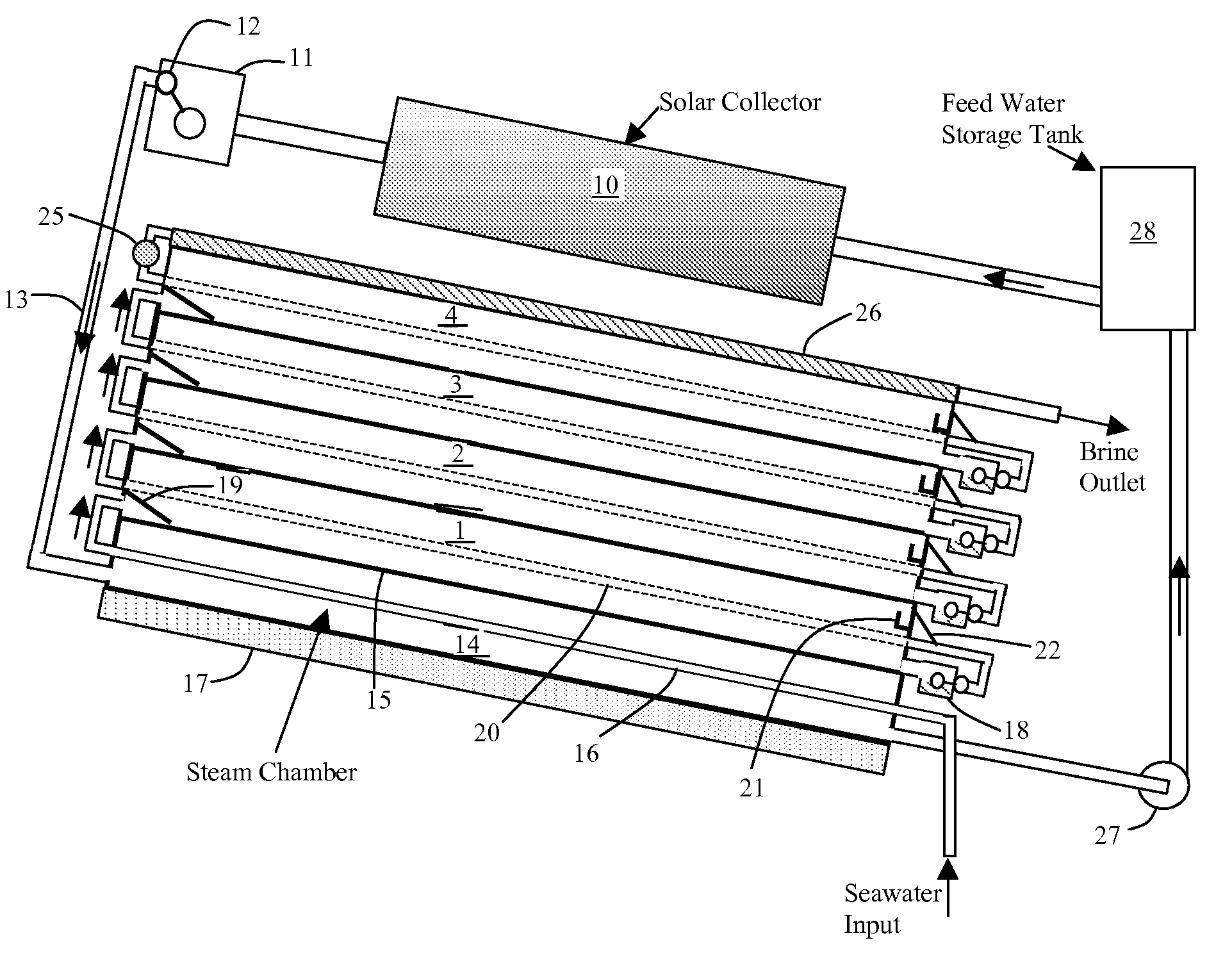

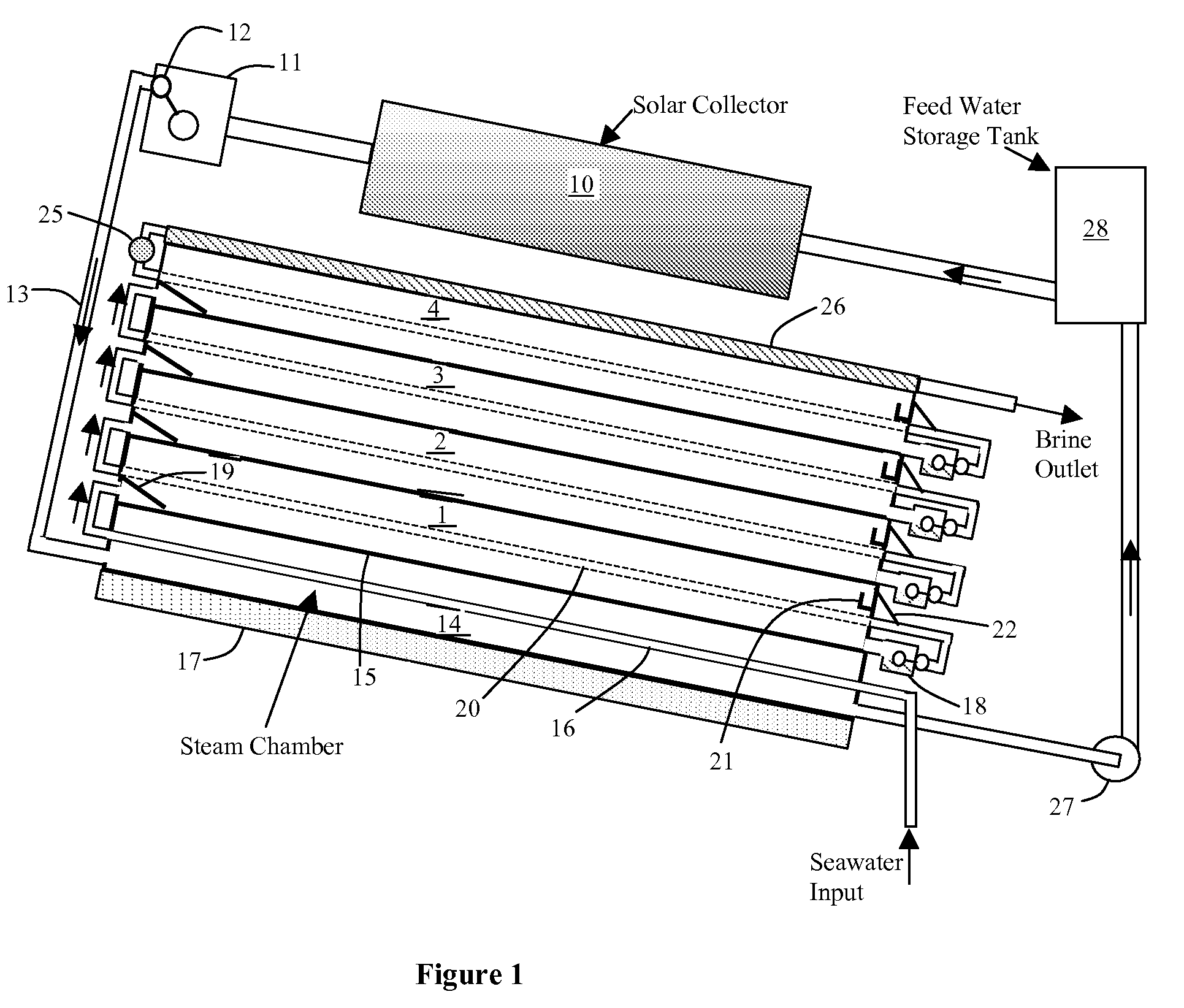

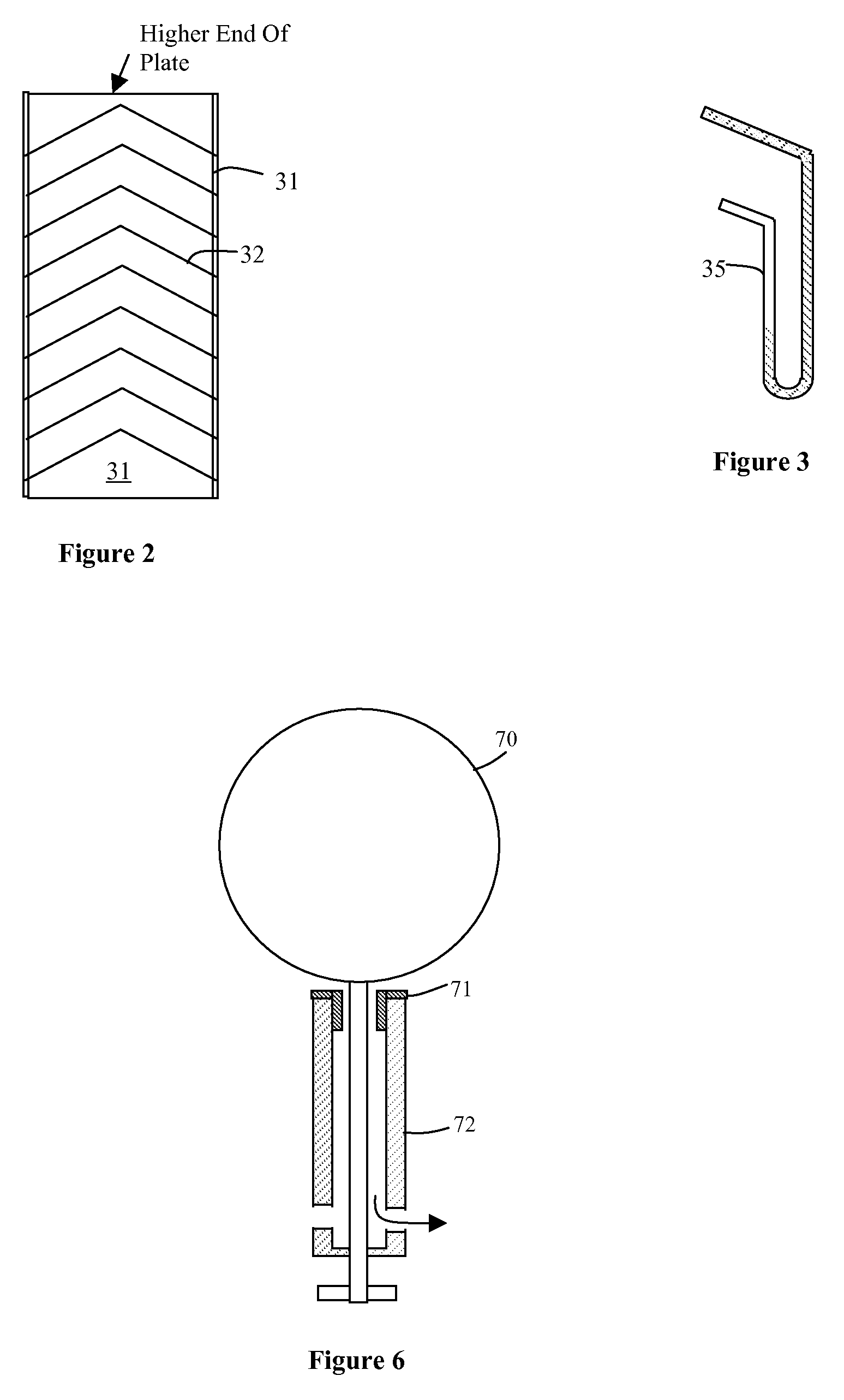

Solar-powered desalination system

InactiveUS20070193870A1Easy to useExcessive numberGeneral water supply conservationMultiple-effect/fractional condensationSaline waterParallel plate

Owner:PRUEITT MELVIN L

Pressure relief device

A pressure relief device having a housing including an inlet, an outlet, and an inner wall defining a bore connecting the inlet and the outlet. The inlet is in communication with a fluid under pressure in a pressure vessel. The bore includes an inlet portion extending from the inlet toward the outlet, and an outlet portion extending from the outlet toward the inlet. The bore also includes a tapered portion connecting the inlet portion and the outlet portion. The inlet portion has a diameter which is less than the outlet portion's diameter. A plug is located in the bore and movable from a closed position, in which flow of fluid through the bore is blocked, to an open position, in which flow of the fluid through the bore is permitted in response to a pressure differential between the inlet and the outlet.

Owner:WESTPORT FUEL SYST CANADA INC

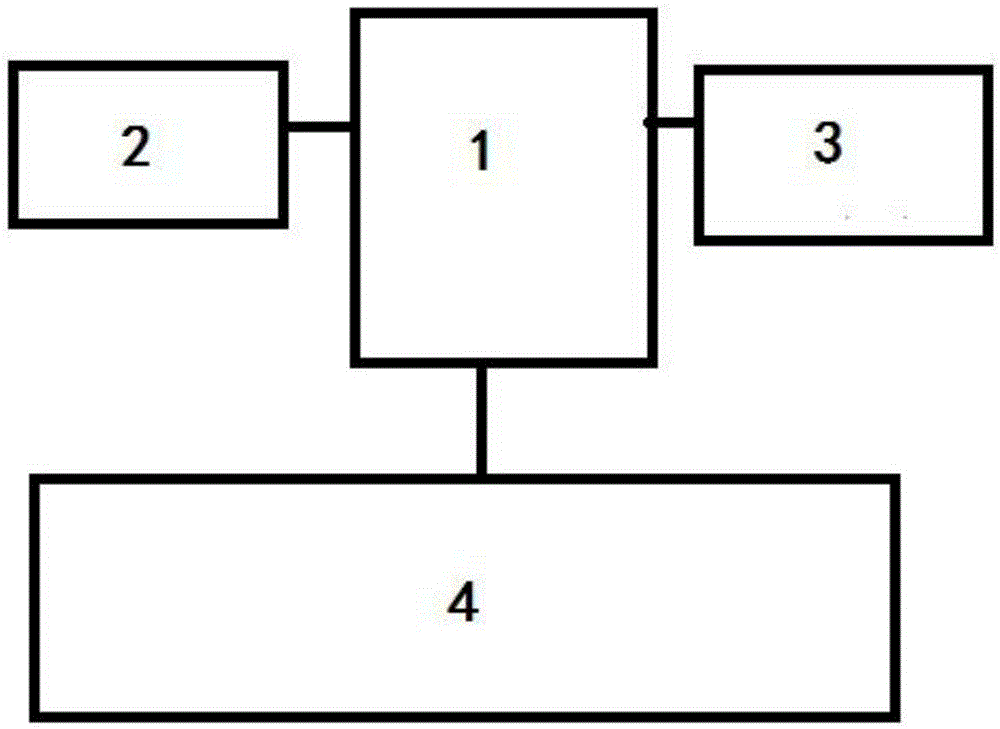

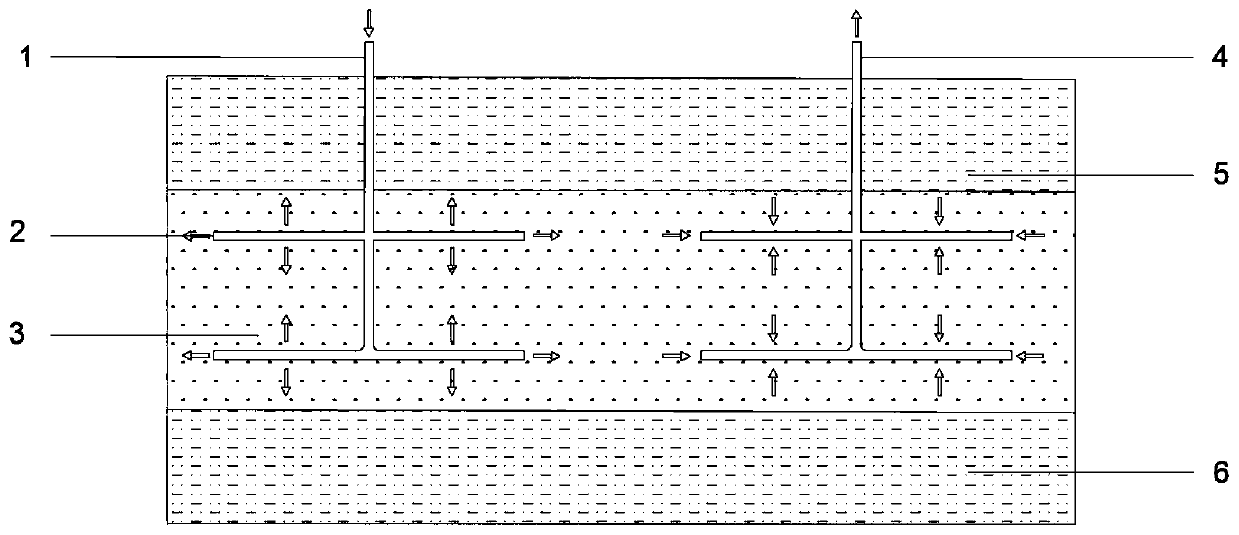

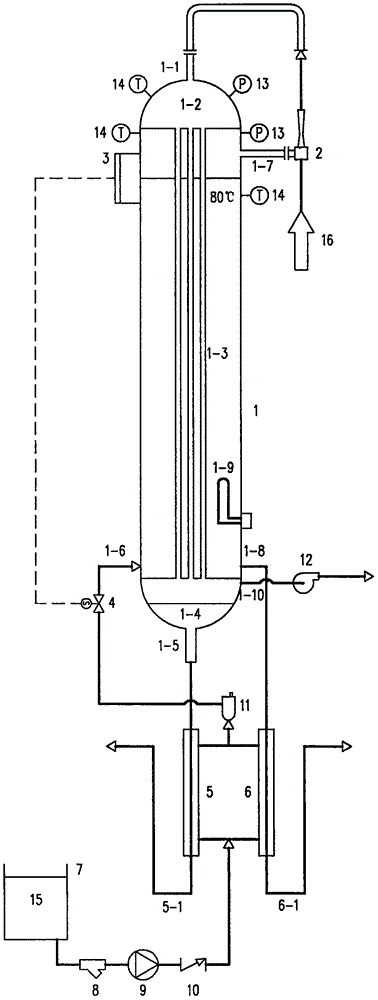

Heat supply secondary pipe network distributed balance control system and control method thereof

ActiveCN102494365AAchieve dynamic balanceGuaranteed differential pressureLighting and heating apparatusEfficient regulation technologiesMicrocontrollerGeneral Packet Radio Service

The invention discloses a heat supply secondary pipe network distributed balance control system and a control method thereof. The system comprises a front-end control system and a tail-end control system and is provided with a master control machine and microcontrollers; and the system is characterized in that: the master control machine is connected with a plurality of microcontrollers through wireless communication; a first pressure transmitter, a second pressure transmitter, a header pipe flowmeter, a variable frequency pump, an electric control valve and a general packet radio service (GPRS) module are connected to the master control machine respectively; and a third pressure transmitter, a fourth pressure transmitter, a branch pipe flowmeter, a balancing control valve and a GPRS module are connected to the microcontrollers respectively. The invention has the advantages that: the pressure difference and flow of a pipe network in each building can be detected, pressure difference between an input end and an output end of the pipe network in each building is guaranteed, pressure difference between a heat supply header pipe and a backflow header pipe is guaranteed, and flow balance between the heat supply header pipe and a heat supply branch pipe is monitored simultaneously; and therefore, the secondary pipe network is operated stably, pipelines are prevented from vibrating, and the service life of the pipelines is prolonged.

Owner:CHONGQING WECAN PRECISION INSTR

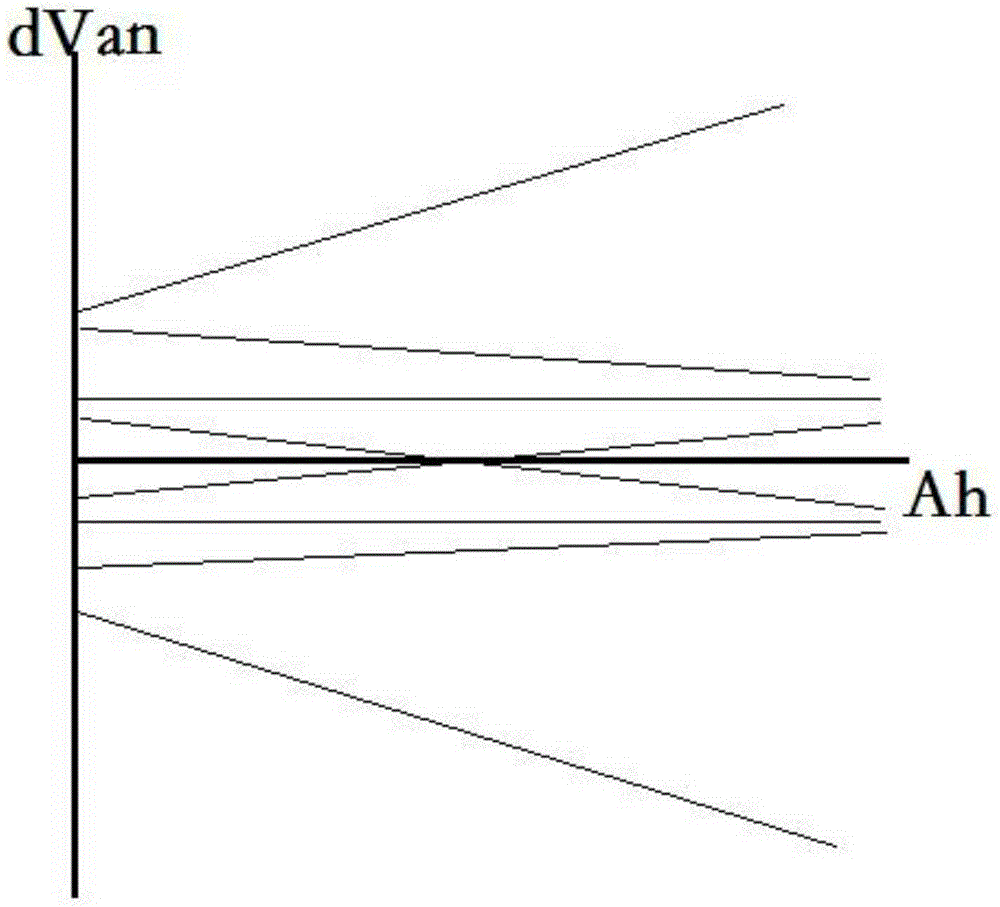

Battery pack active equalization method and battery pack active equalization device

ActiveCN105356533AHigh precisionReduce test errorBatteries circuit arrangementsSecondary cells charging/dischargingEqualizationPressure difference

Owner:HIGER

Working defrosting method of variable-frequency air-conditioner

InactiveCN110094832APrecise defrostingEasy accessMechanical apparatusSpace heating and ventilation safety systemsFour-way valveFrequency reduction

The invention discloses a working defrosting method of a variable-frequency air-conditioner. The working defrosting method provides two defrosting modes of defrosting during heating start-up and defrosting during normal working; the function of defrosting during heating start-up of the method comprises the following steps that the outdoor temperature and the coil temperature are judged before start-up is carried out, so that the situation that the heating effect is reduced due to the thickening of a frost layer caused by the fact that a heating mode is directly started is avoided, and meanwhile, an indoor evaporator is preheated, so that the air conditioner can enter a heating state faster, and the heating effect is better; and according to the method, the defrosting process during normalworking comprises the following steps that a compressor is subjected to frequency reduction treatment, after working stably, the compressor stops working, the opening degree of an electronic expansionvalve is maximum, enough time is given to balance the air pressure difference brought by airflow impact, and then a four-way valve is reversely rotated, so that the noise is reduced, and the better experience effect is given to the user.

Owner:CHUZHOU XINGLIAN ELECTRONICS CO LTD

Carbon dioxide inhibitor-combined natural gas hydrate replacement mining method

InactiveCN109915094AExtend build timeIncrease the spread distanceFluid removalPressure differenceInjection well

Owner:DALIAN UNIV OF TECH

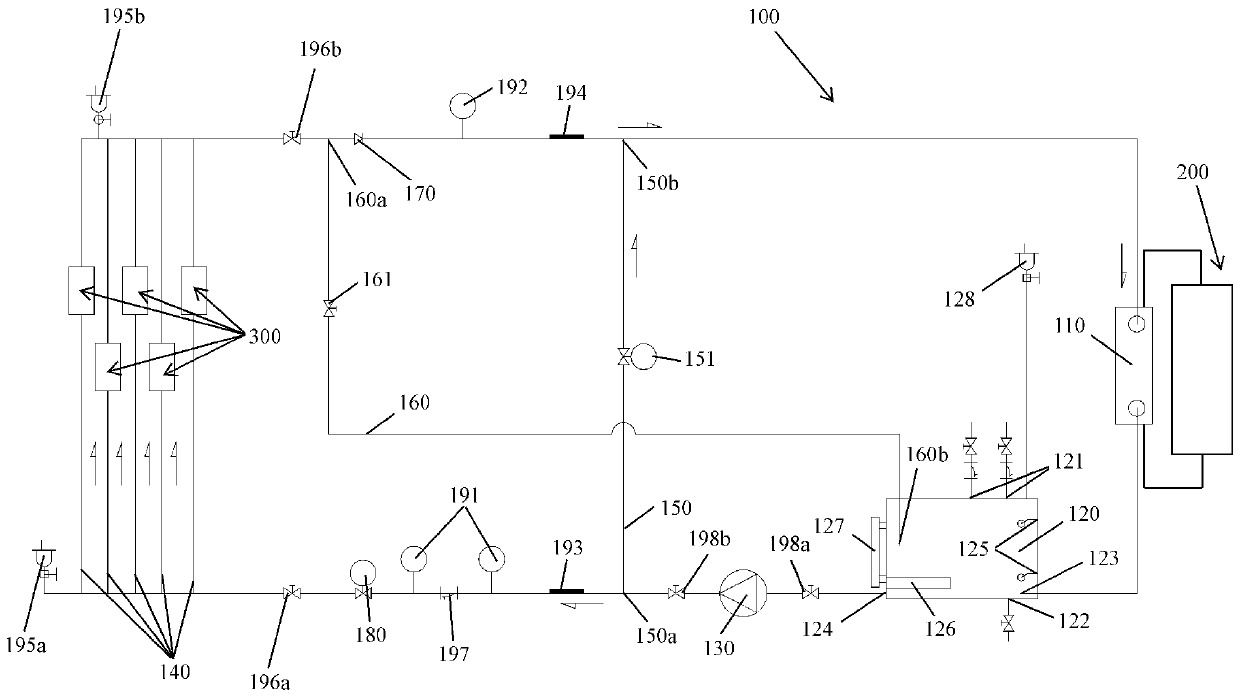

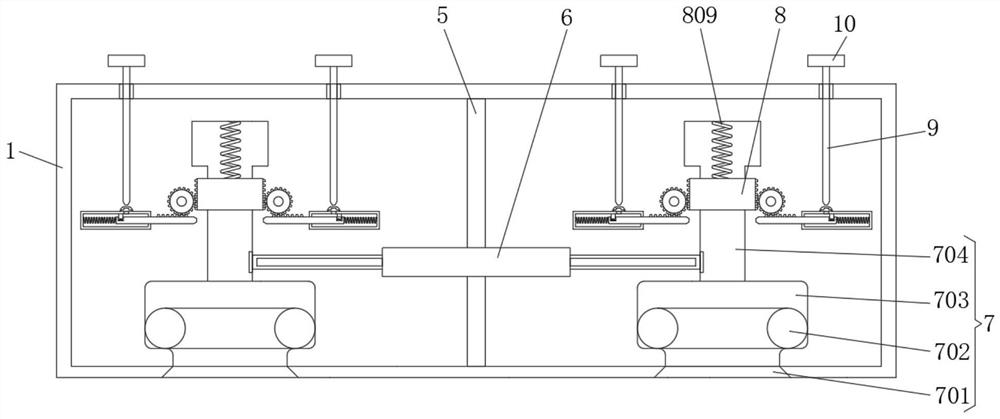

Pressure pulse testing machine

InactiveCN103499415AFast loadingQuick uninstallFluid pressure measurementNatural productPulse test

The invention provides a pressure pulse testing machine, and aims to solve the problem of inaccurate control of measuring parameters and waveforms due to pressure difference existing among each pressurizing point in the conventional pressure pulse technology although air pressure serving as a constantly-existing natural product can be used for effectively detecting a pressure sensor. Technical key points of the invention are that an air storing cabinet comprises a primary pressure cavity and a secondary pressure cavity; the primary pressure cavity is connected with an air pump; the upper part of the secondary pressure cavity is provided with an elastic connector, an air inlet servo valve and a standard pressure cavity in sequence; the side wall of the standard pressure cavity is provided with an exhaust electromagnetic valve group and an adjusting electromagnetic valve; pressurizing holes are uniformly distributed in the upper surface of the standard pressure cavity; a pressure sensor of a standard sensor with a waveform feedback measuring function is arranged in at least one of the pressurizing holes. The pressure pulse testing machine has the positive effects that fatigue test can be performed on a tested object under the condition that the tested object is not damaged. The pressure pulse testing machine further has the characteristics of high control degree, low cost, stability, reliability, high practicability and the like.

Owner:SHENYANG ACAD OF INSTR SCI

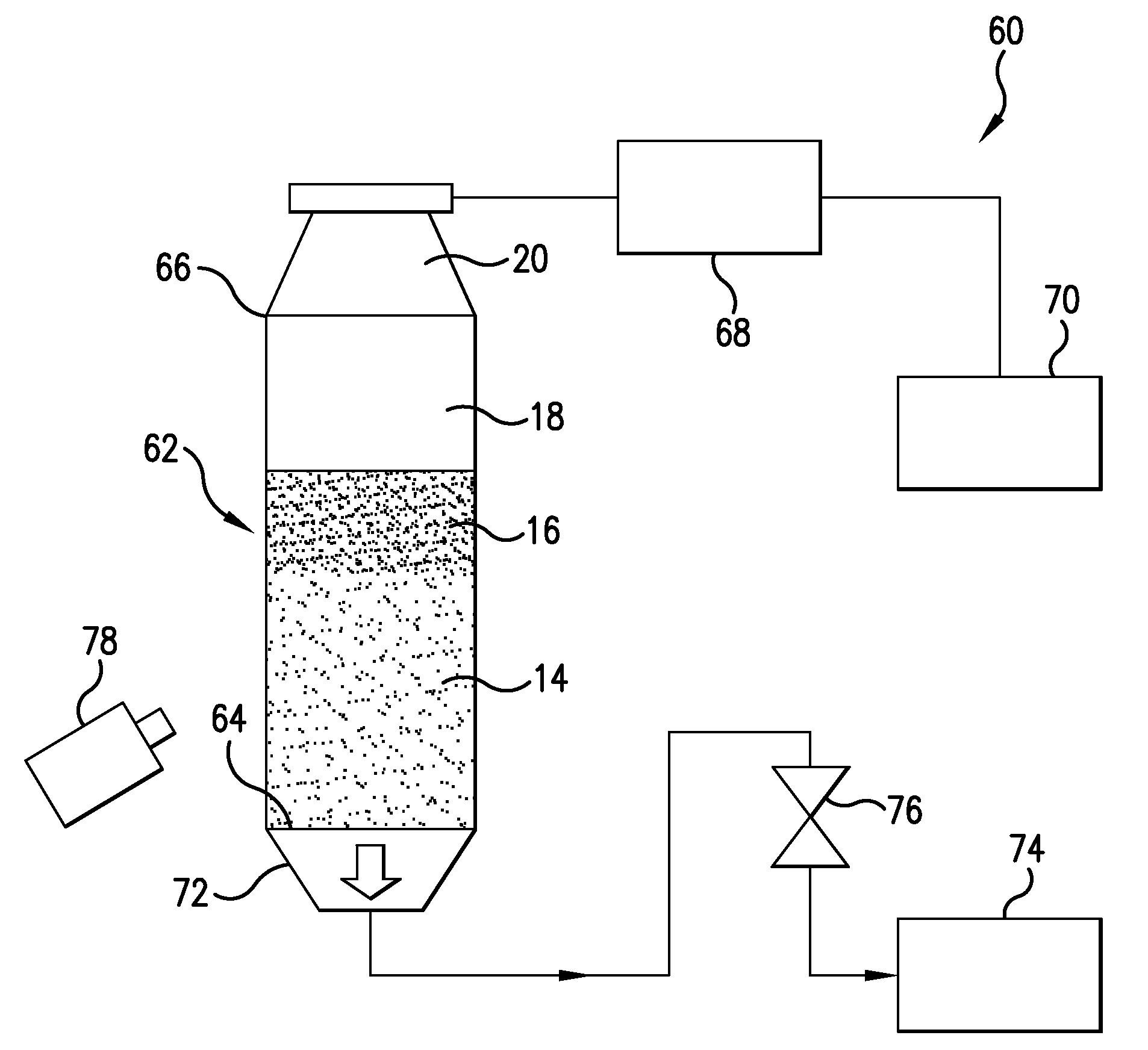

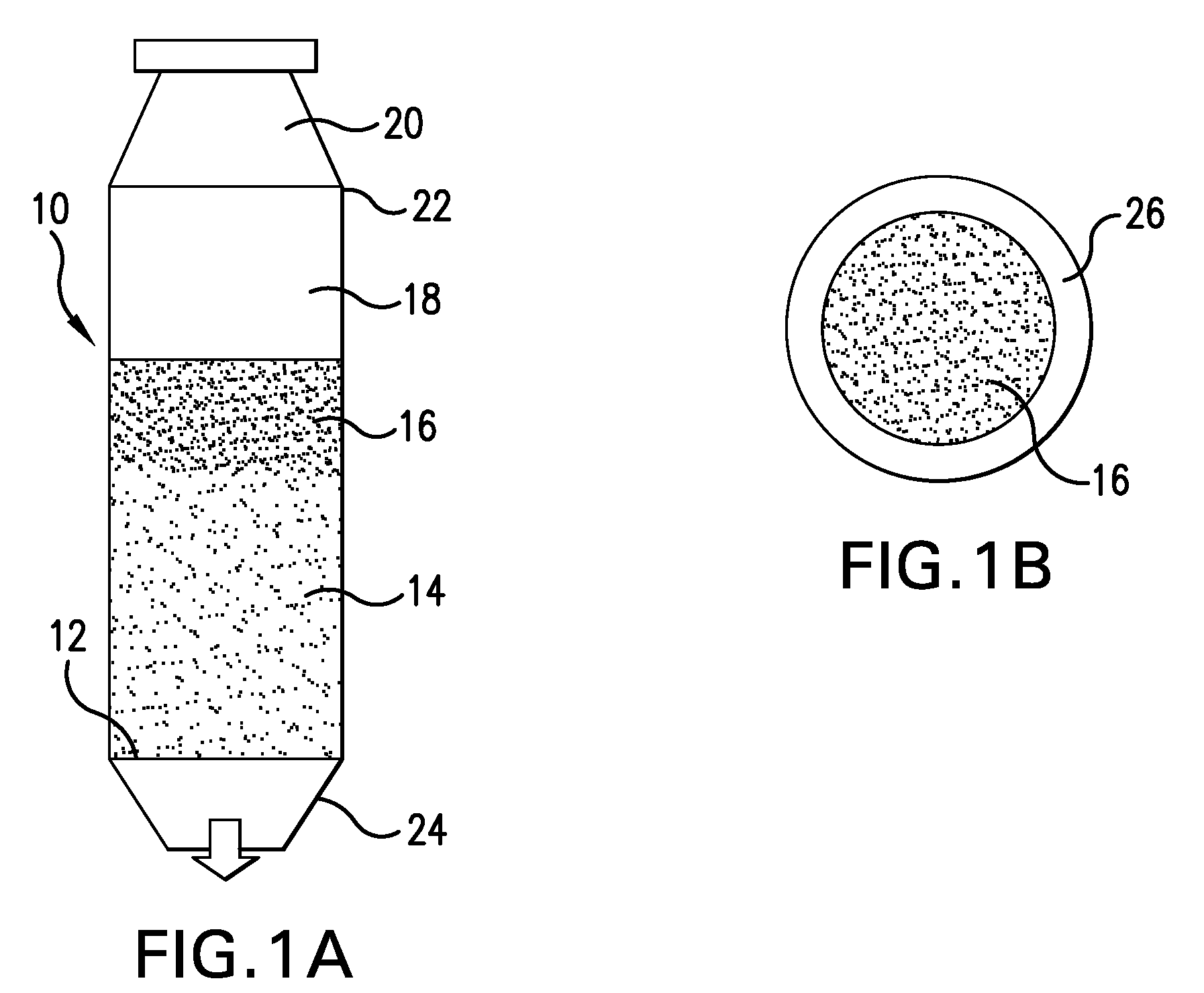

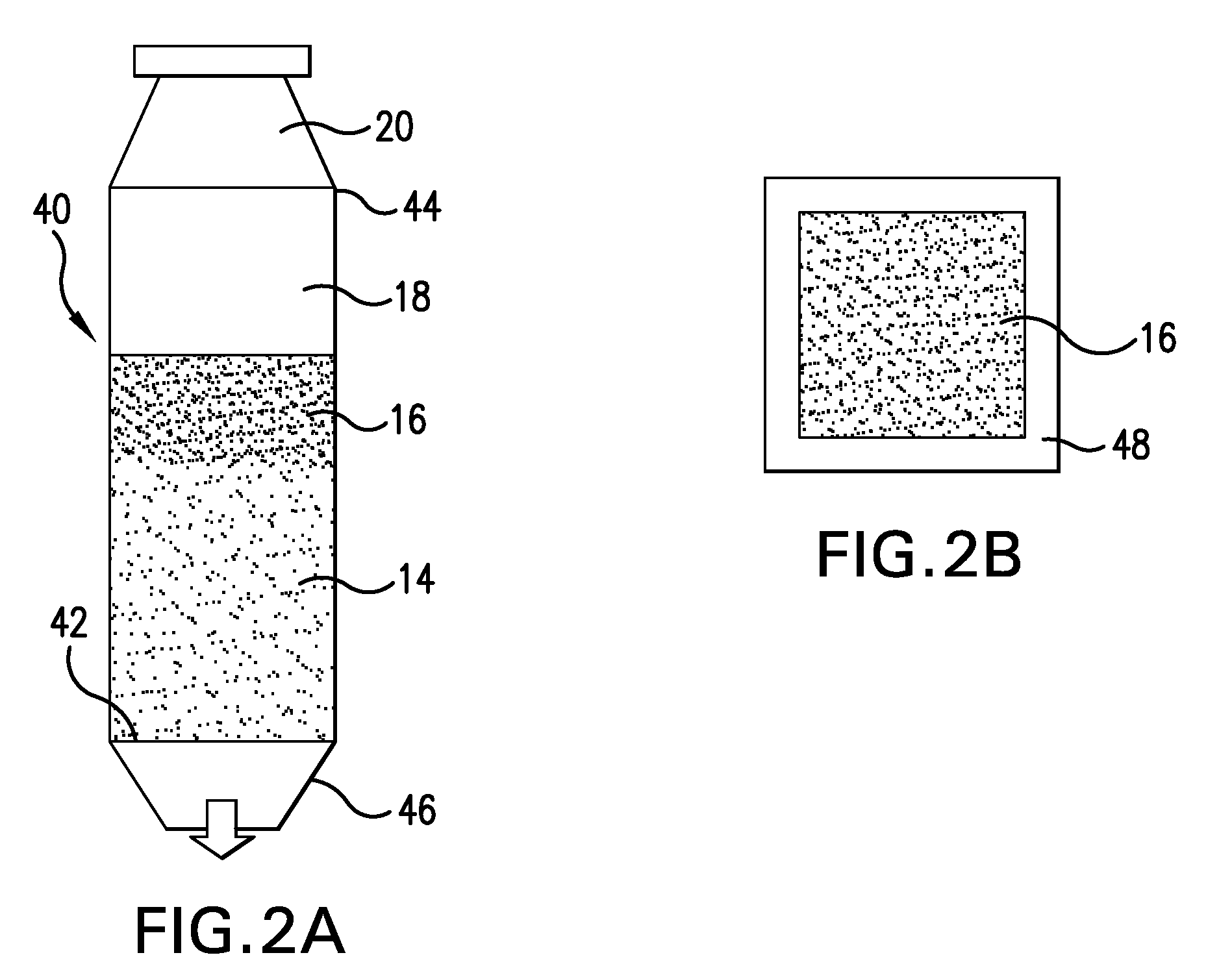

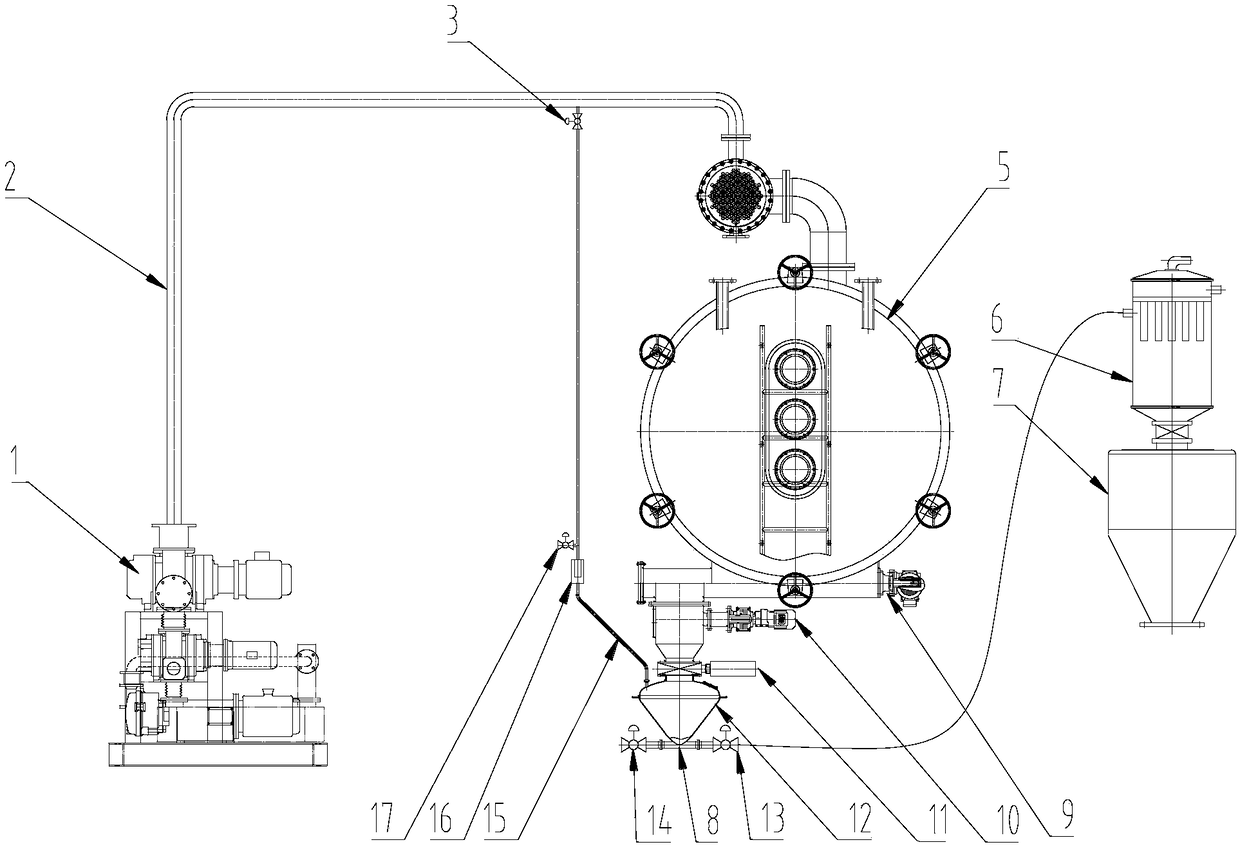

Mixing and packing of particles

InactiveUS20090272078A1Well mixedLower the volumeShaking/oscillating/vibrating mixersPackaging by pressurising/gasifyingParticulatesVolumetric Mass Density

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY +1

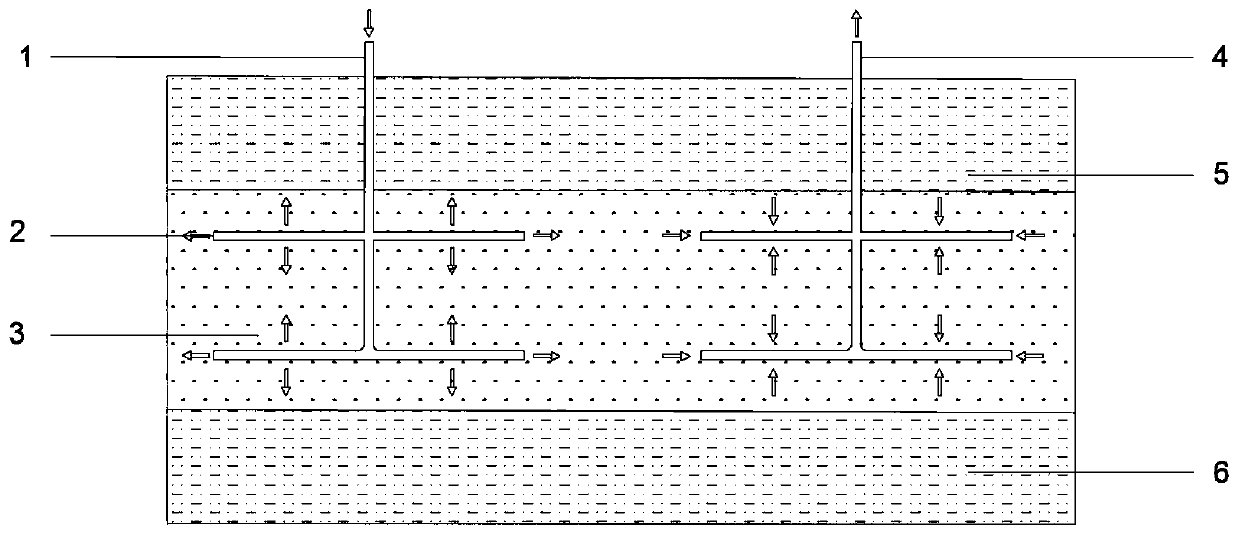

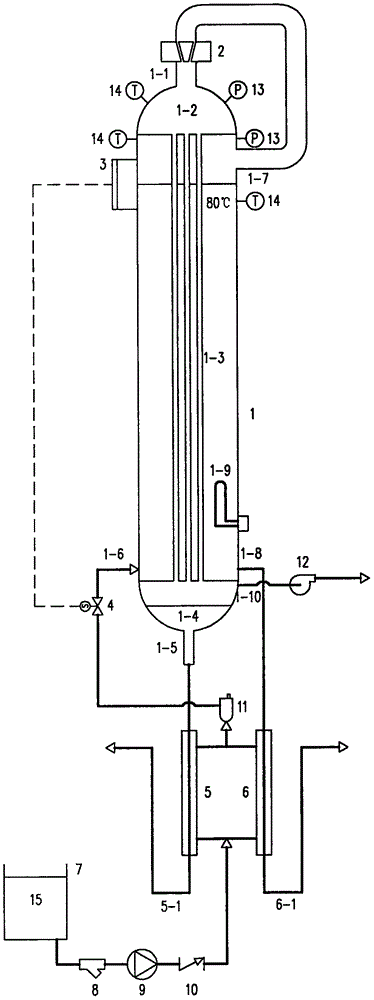

Siphon circulation, contraflow heat regeneration and vapor compression distillation device

InactiveCN105920863ASave investmentSave power consumptionEvaporation with vapour compressionSeawater treatmentSiphonWater vapor

Owner:侴乔力 +1

Device and method for measuring underground flow rate of petroleum well

The invention discloses a device and a method for measuring underground flow rate of a petroleum well. The device comprises a ground logging truck, and an instrument string which is connected through a cable and arranged in a sleeved oil pipe of an underground sleeve, wherein the instrument string comprises a halter, a first centering device, a magnetic positioning shot, a second centering device, a pressure difference density meter, a flow logger, a third centering device and a plug; a circuit system control motor or a hydraulic driving arm is mounted on the flow logger; static pressure sampling openings are respectively formed in the control motor or the hydraulic driving arm and the pressure difference density meter; the control motor or the hydraulic driving arm is opened or closed to measure underground flow rate of the petroleum well. According to the device, minimum annular section area between the arm and the sleeve is adjusted through the flow logger, so that the flow logger can be adapted to oil wells with various size and aperture; the construction processes are decreased; the working cost is saved; the working hours are reduced; the flow logger is applied to measuring of flow rate of a vertical shaft and a large-inclination-degree well, and the measuring precision is high.

Owner:XIAN WEISHENG ELECTRONIC INSTR CO LTD

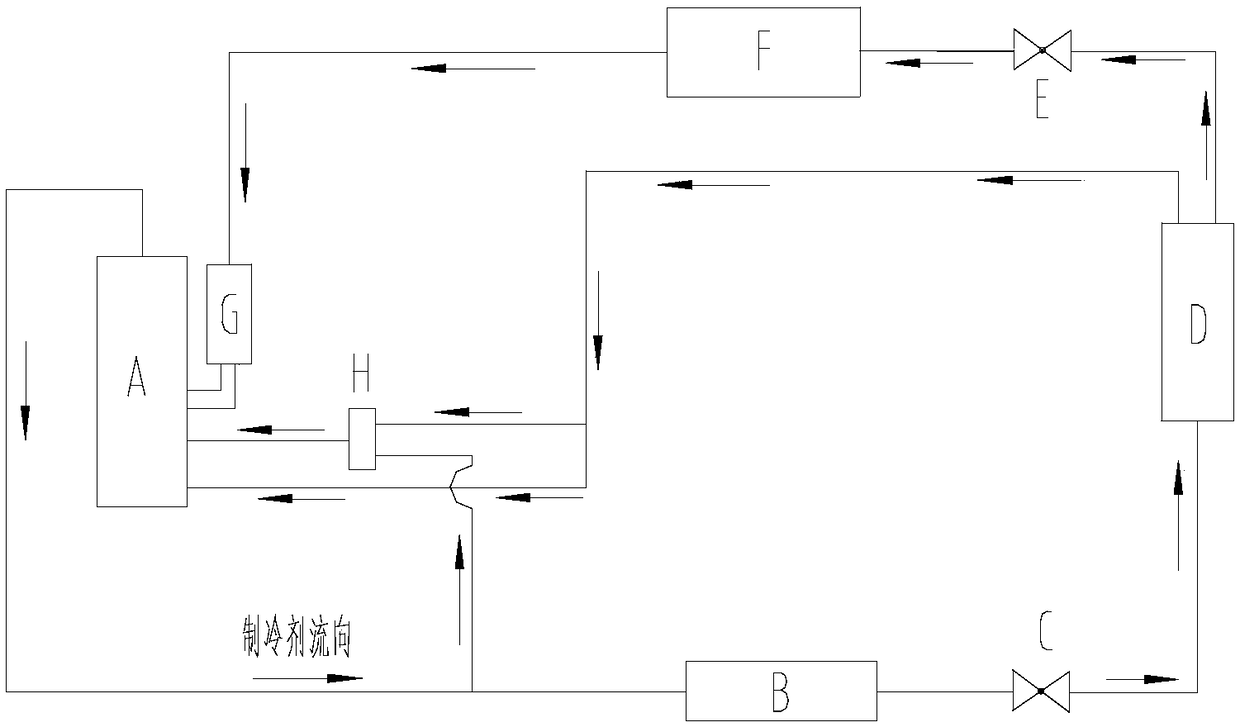

Battery cooling system, vehicle power exchange system and battery cooling control method

ActiveCN109638377AStable jobImprove cooling effectSecondary cellsVehicular energy storageElectricityPower exchange

Owner:NIO ANHUI HLDG CO LTD

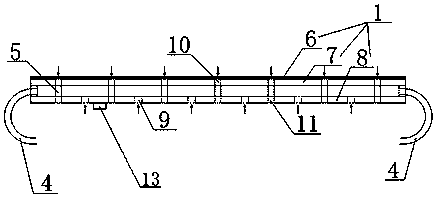

Chain type flow automatic regulator

The technical problem to be solved by the invention is as follows: the existing cement clinker cooling machine can not automatically adjust the cooling air. The invention provides an automatic flow regulator which can adjust the input air according to the magnitude of material layer resistance. The chain-typed automatic flow regulator comprises an air inlet pipe provided with an adjustable inlet opening, and a follow-up unit which moves along with the increase of the pressure difference between the interior and exterior of the air inlet pipe to lead the ventilated area of the adjustable inlet opening to gradually decrease.

Owner:NANJING XIPU CEMENT ENG GROUP

Vacuum belt type dryer material dust continuous discharge system

PendingCN108946175AGuaranteed filter effectImprove drying recoveryDrying solid materials without heatDrying machines with progressive movementsBuffer tankInlet valve

Owner:常州朗脉洁净技术有限公司

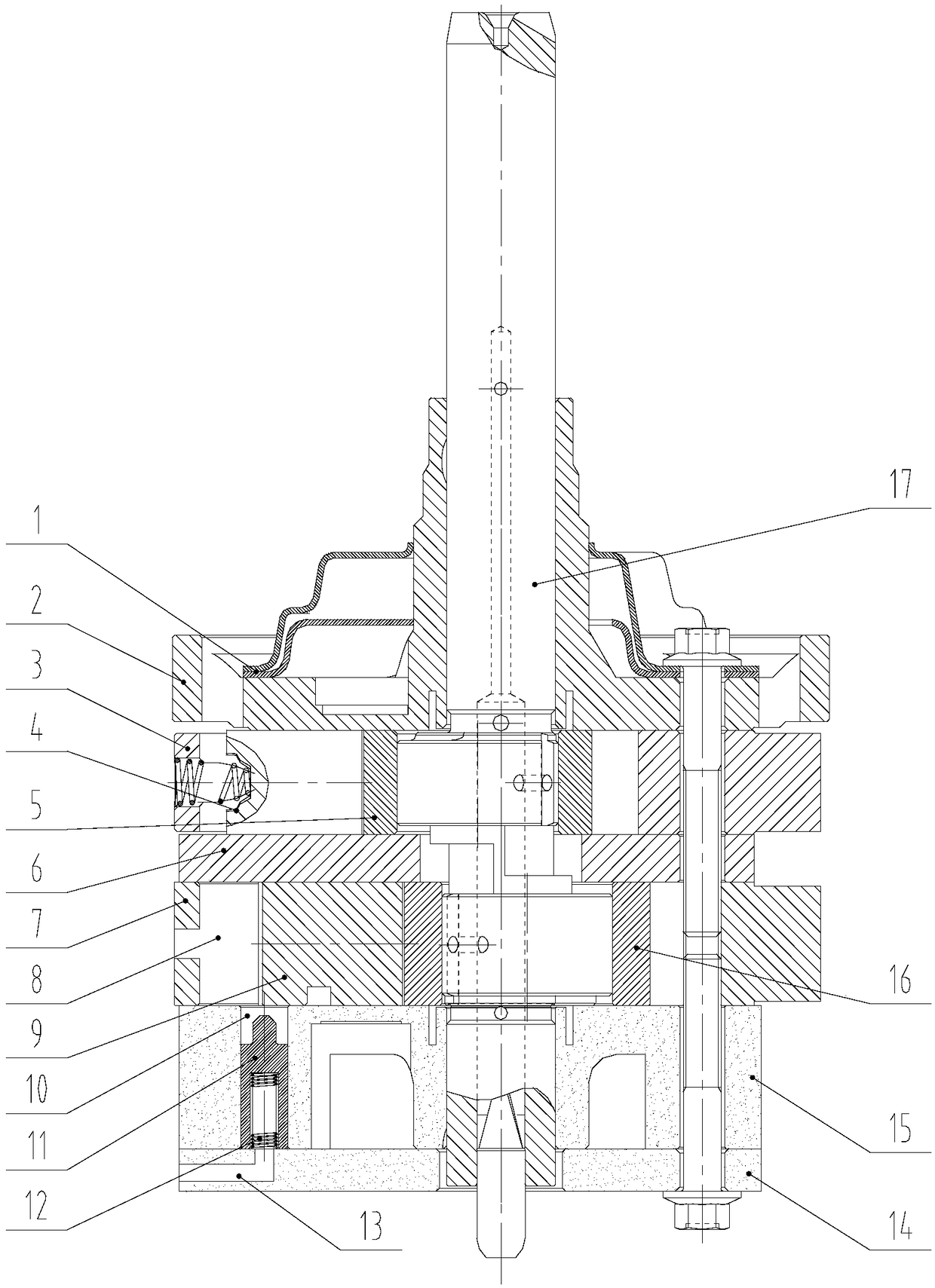

Variable capacity compressor and air conditioning system thereof

ActiveCN109236651AImprove reliabilityAdjustable pressure valueRotary piston pumpsRotary piston liquid enginesReciprocating motionEngineering

Owner:GREE ELECTRIC APPLIANCES INC +1

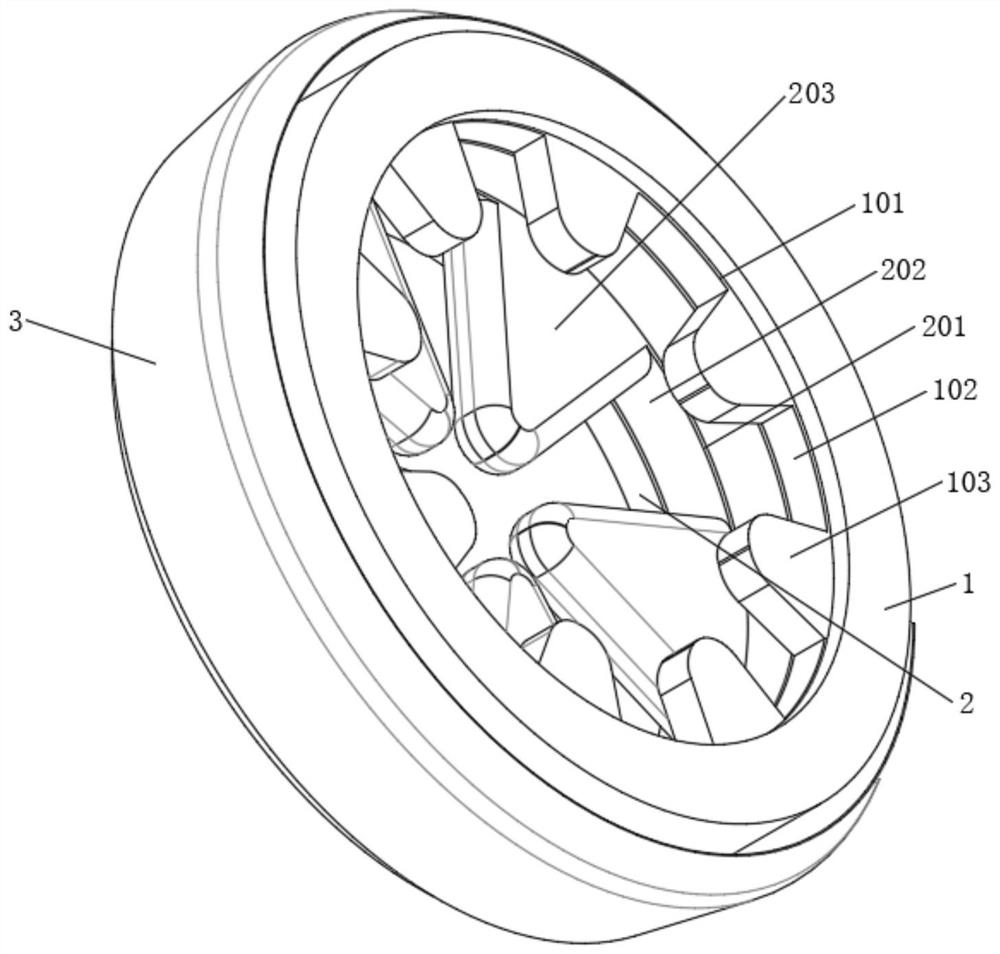

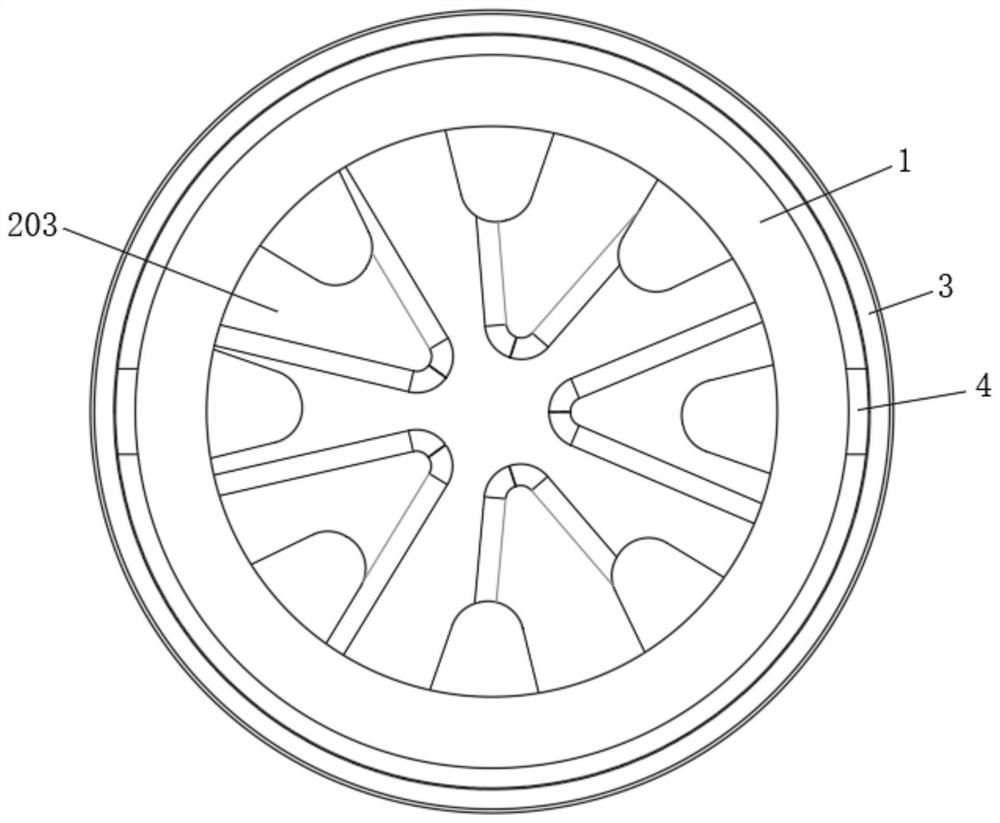

Hub-free rim propeller

Owner:赣州市潜行科技有限公司

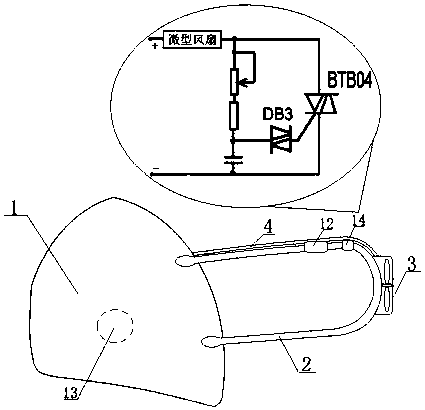

Medical gas replacement type mask

ActiveCN108095228AAchieve replacementComfortable to useGarment special featuresProtective garmentRespiratorEngineering

Owner:殷霞 +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap