Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

19 results about "Chemical industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The chemical industry comprises the companies that produce industrial chemicals. Central to the modern world economy, it converts raw materials (oil, natural gas, air, water, metals, and minerals) into more than 70,000 different products. The plastics industry contains some overlap, as most chemical companies produce plastic as well as other chemicals.

Hexavalent-chromium wastewater treatment technology

Owner:CANGZHOU HONGHAI CHEM CO LTD

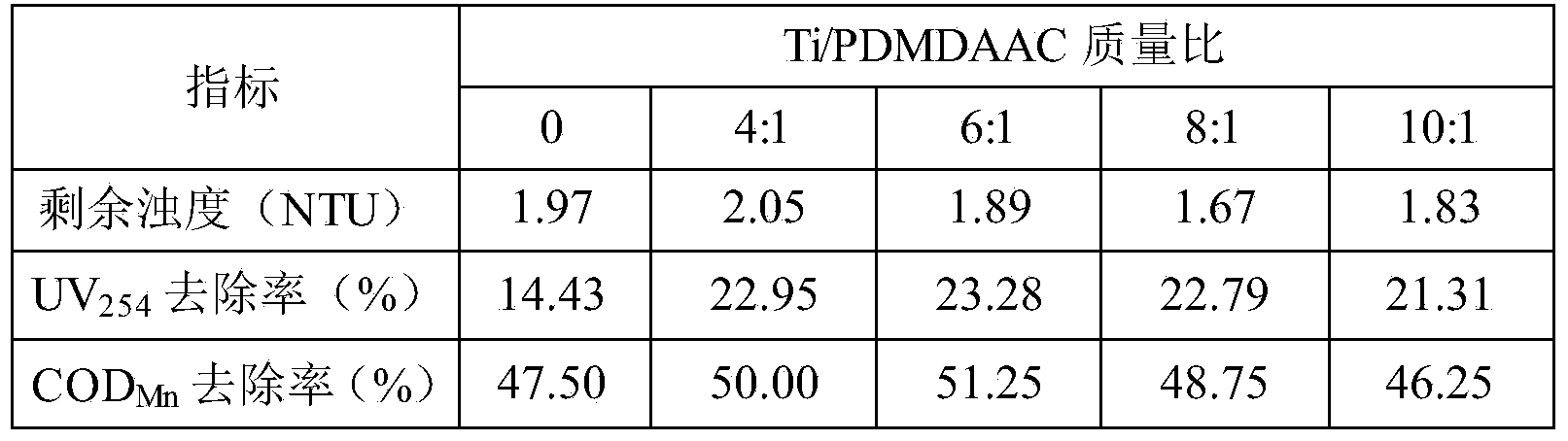

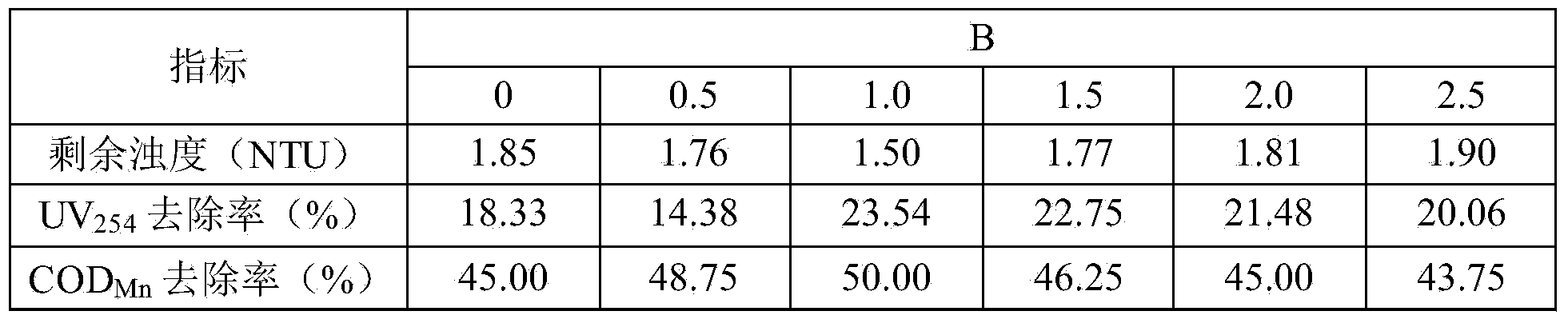

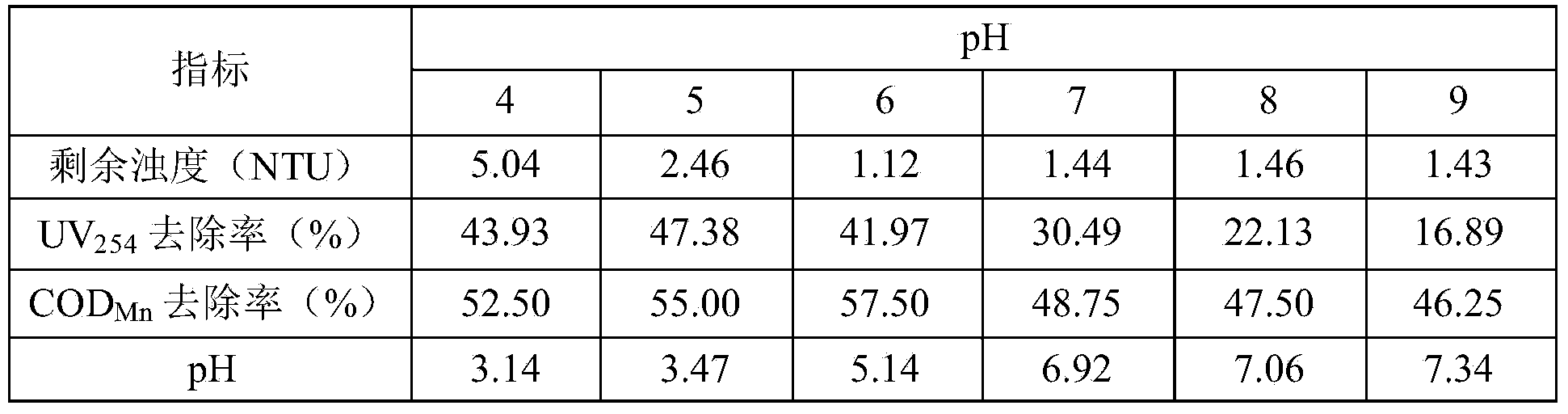

Polymeric titanium sulfate-PDMDAAC (poly dimethyl diallyl ammonium chloride) composite coagulant as well as preparation and application methods thereof

InactiveCN103964554AWater/sewage treatment by flocculation/precipitationChemical industryWater supply

Owner:TONGJI UNIV

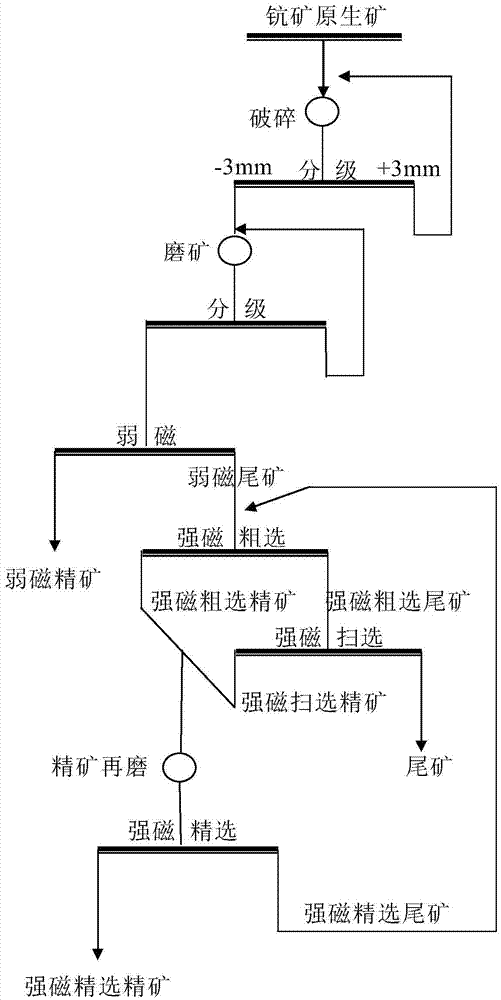

Mineral separation and enrichment method for primary scandium ore

ActiveCN105435958ASimple processEconomically reasonableMagnetic separationWet separationChemical industryEnrichment methods

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Environmentally friendly polyvinyl chloride coating

InactiveCN104861793AGood weather resistanceImprove temperature resistanceAnti-corrosive paintsPolyamide coatingsChemical industryChemistry

The invention discloses an environmentally friendly polyvinyl chloride coating. The coating comprises, by mass, 35-70% of polyvinyl chloride resin, 5-10% of dioctyl phthalate, 5-15% of polyethylene resin, 5-10% of talcum powder, 3-8% of rutile titanium dioxide, 3-5% of polyether modified polysiloxane, 2-3% of N-hydroxyethylethylamine triacetic acid, 1-3% of polyether esteramide, 0.5-1.5% of a calcium and zinc stabilizer, 0.1-0.5% of polyoxyethylene amide, 0.5-1% of calcium stearate and 4-8% of polyisocyanate. The environmentally friendly polyvinyl chloride coating has the advantages of excellent weather resistance, excellent temperature tolerance, excellent corrosion resistance and good environmental protection performance, and can be used in the chemical industry, the petroleum industry, the pharmacy industry and the food industry to form protection coat layers of surfaces of devices, buildings and members.

Owner:殷培花

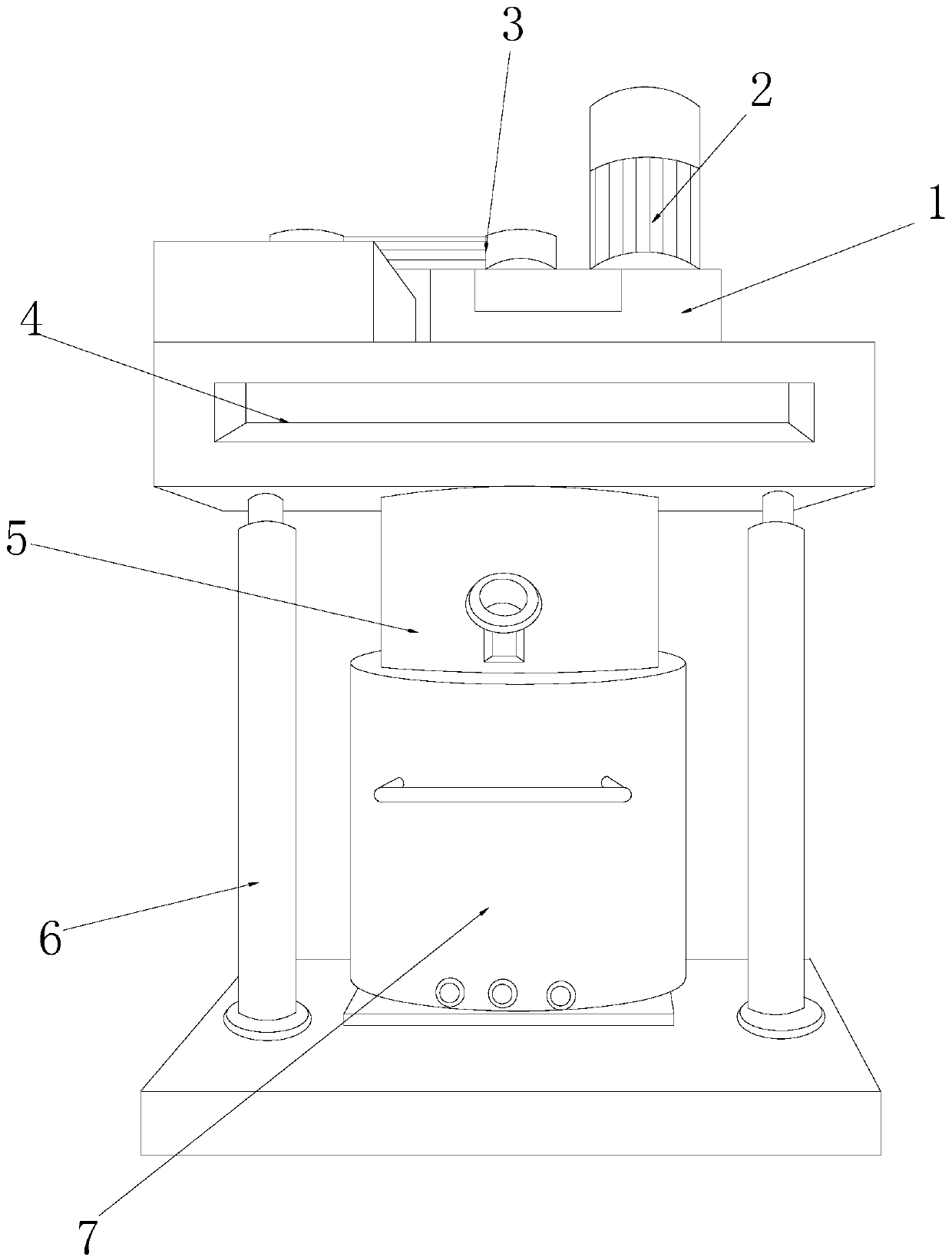

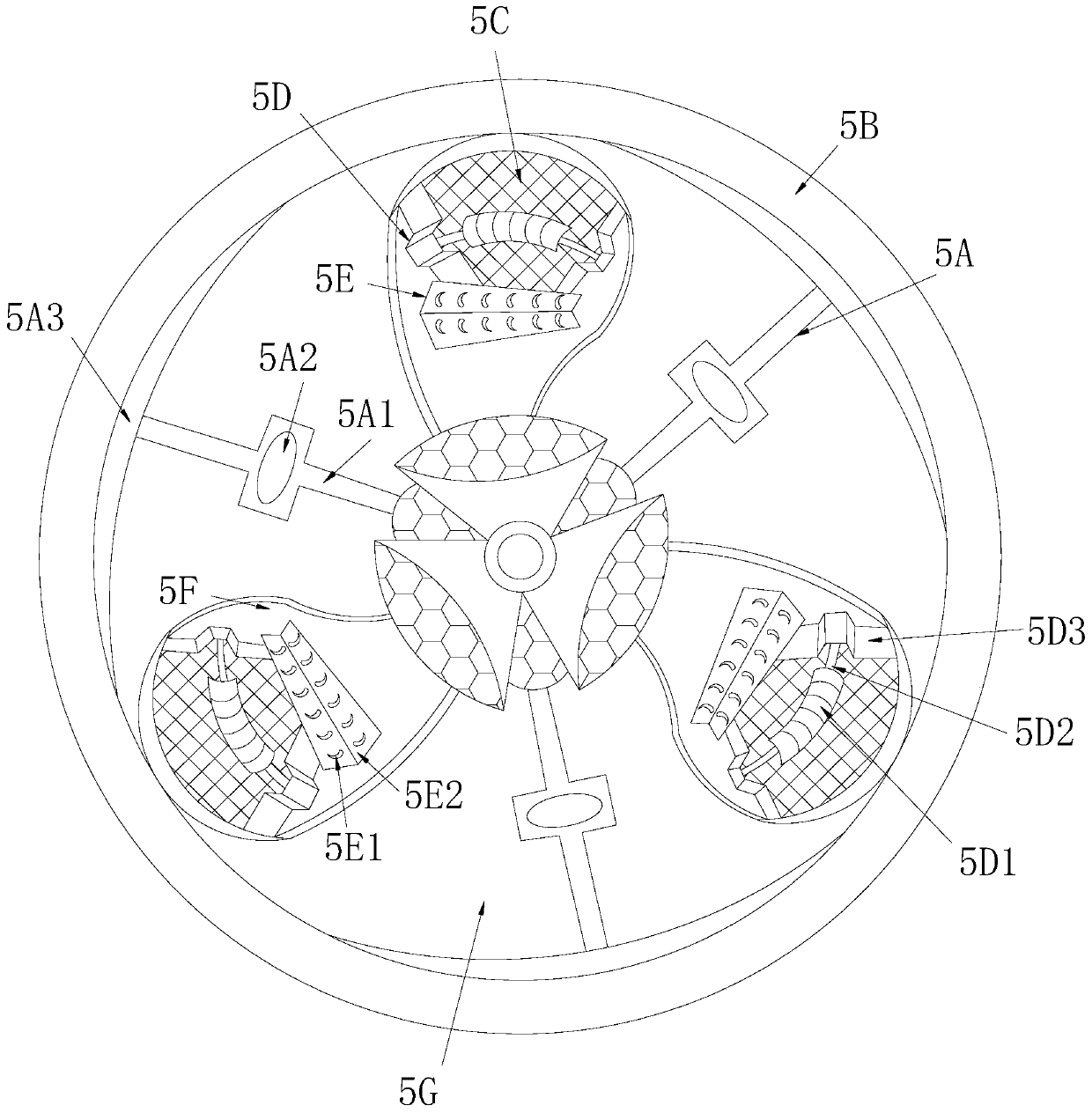

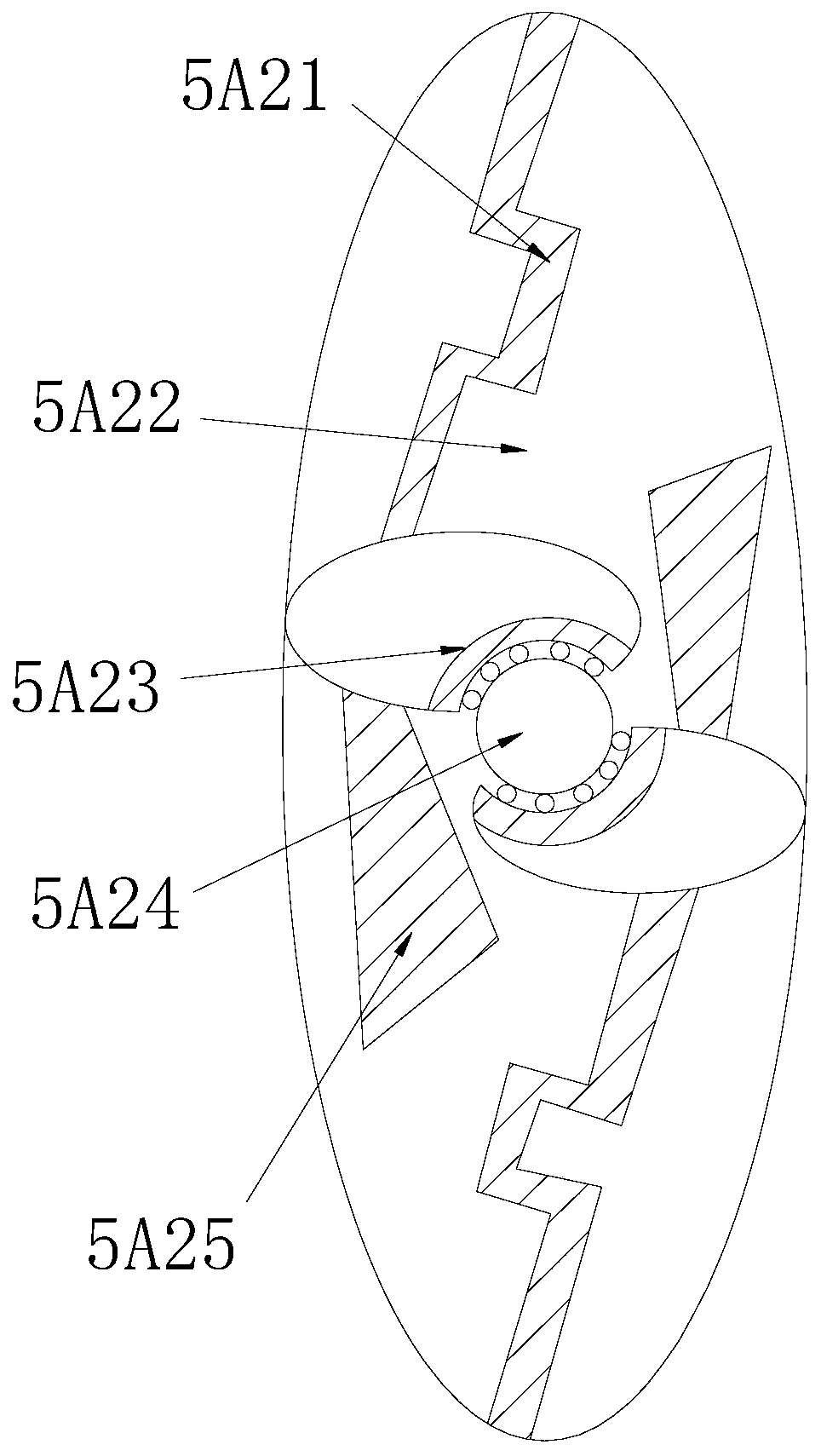

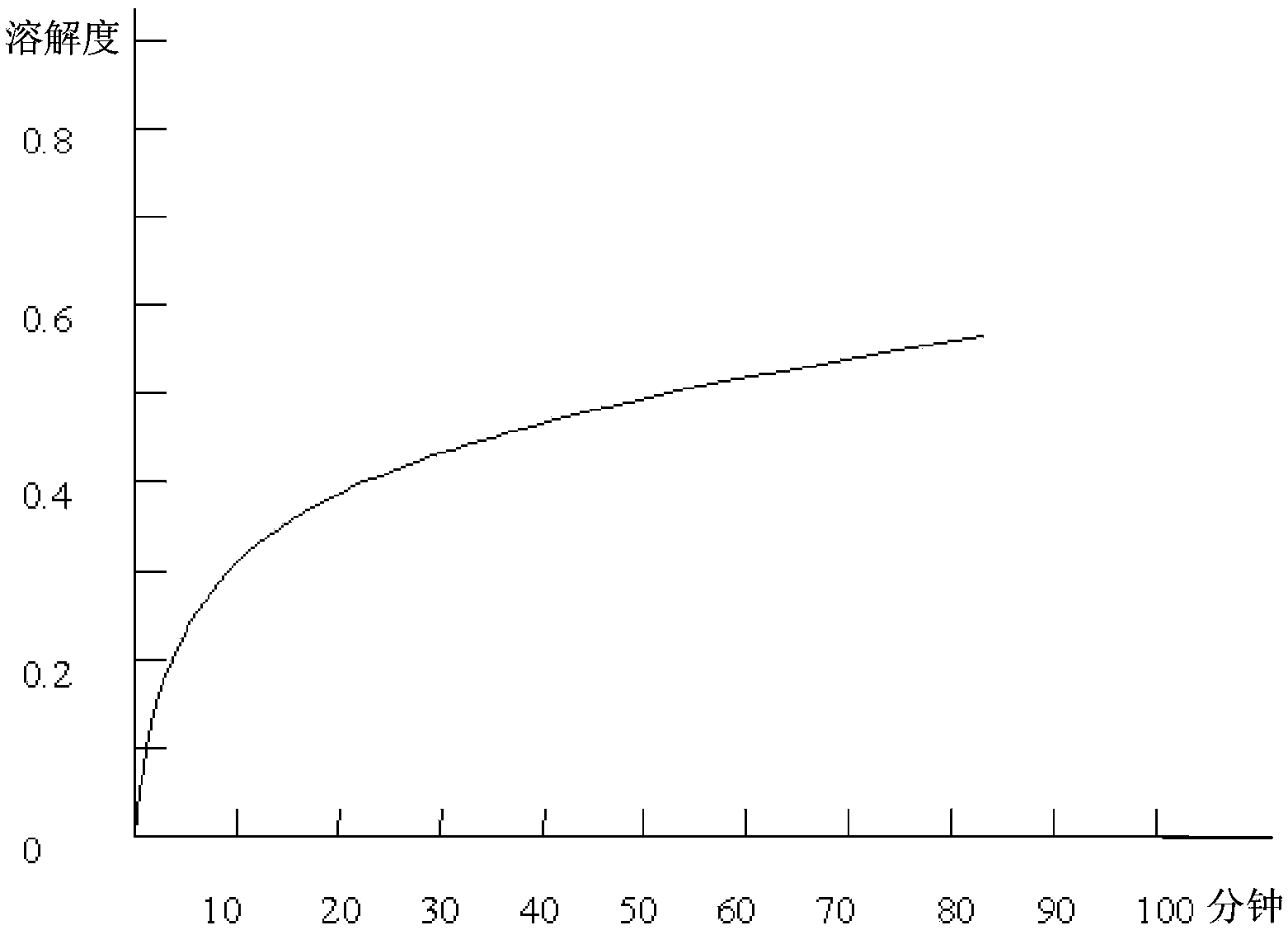

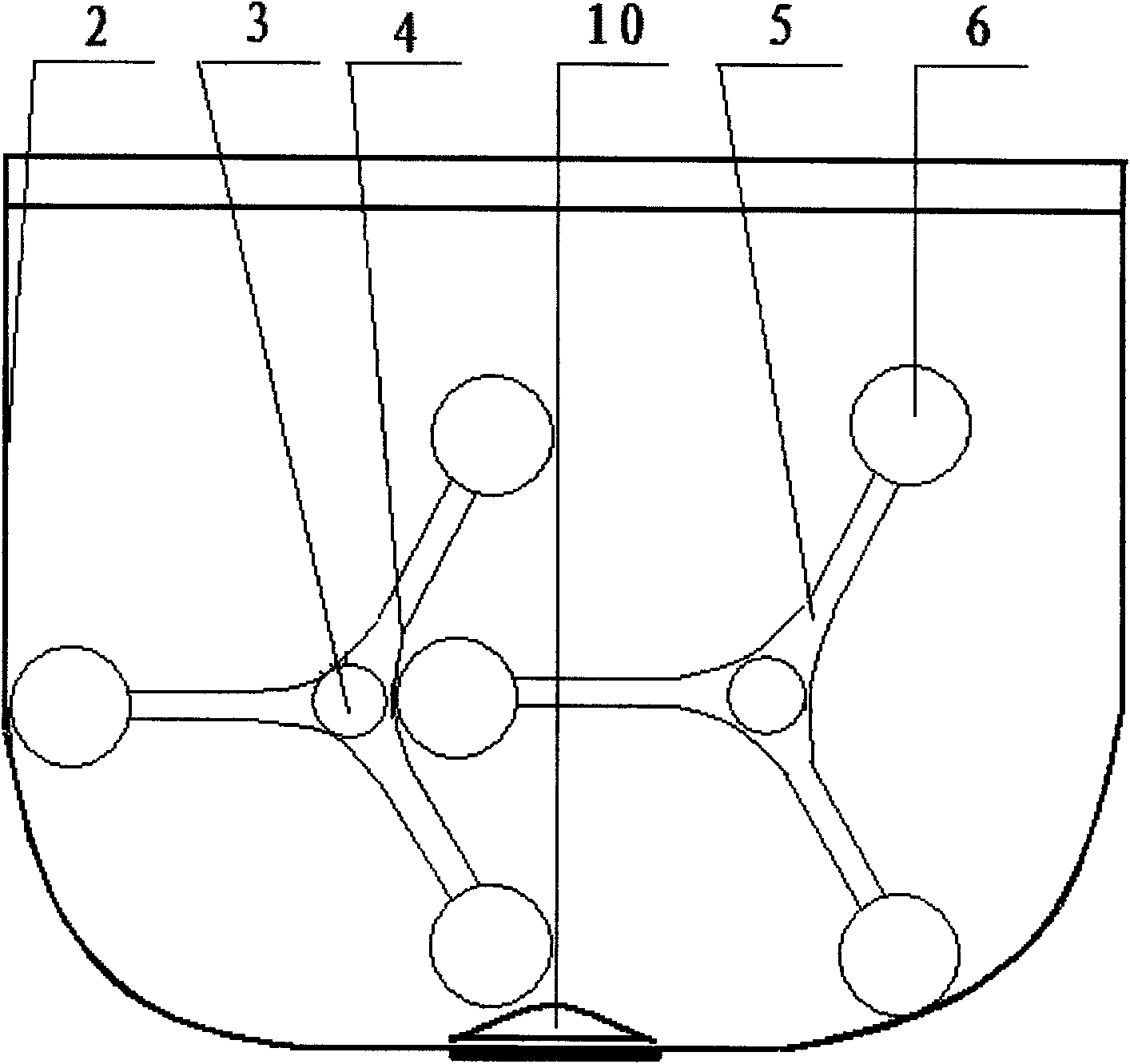

Chemical mechanical stirrer based on paddle wing barbs for organic silica gel

InactiveCN111330474ARotary stirring mixersTransportation and packagingChemical industryHydraulic cylinder

Owner:吴金元

Desulfurization additive as well as applications and using method of same

InactiveCN103446870ABuffer pH dropHigh reactivityDispersed particle separationChemical industryReaction rate

Owner:BEIJING HUADIAN ZHUOYUE TECH CO LTD

Method for purifying nitrilase

InactiveCN102363775AImprove purification efficiencyHigh purityLyasesChemical industryUltrafiltration

The invention relates to a method for purifying nitrilase and belongs to a preparation method for the nitrilase. By the method, the purified nitrilase product is prepared from commercial coarse nitrilase by the simple process of preprocessing, ultrafiltration and classification, and freeze drying. The method is simple; the conventional simple equipment is adopted; the method is easy to operate and control, and convenient to popularize and apply, and the production is safe; in the production process, the reaction condition is mild, energy consumption is low, material resources are utilized completely, emission is avoided, and environmental protection is facilitated; and the produced product has high purity, activity and stability and can meet the requirement on preparation of products with high additional value. The product prepared by the method can be widely applied to the industries such as medicines, chemical industry, materials, agriculture and the like.

Owner:CHONGQING UNIV

Nylon enhanced rubber conveyer belt

InactiveCN101879979AExtended service lifeOptimize the process routeConveyorsProduction lineNylon material

Owner:XIANGFAN ABSB AUTOMOBILE ABSORBER

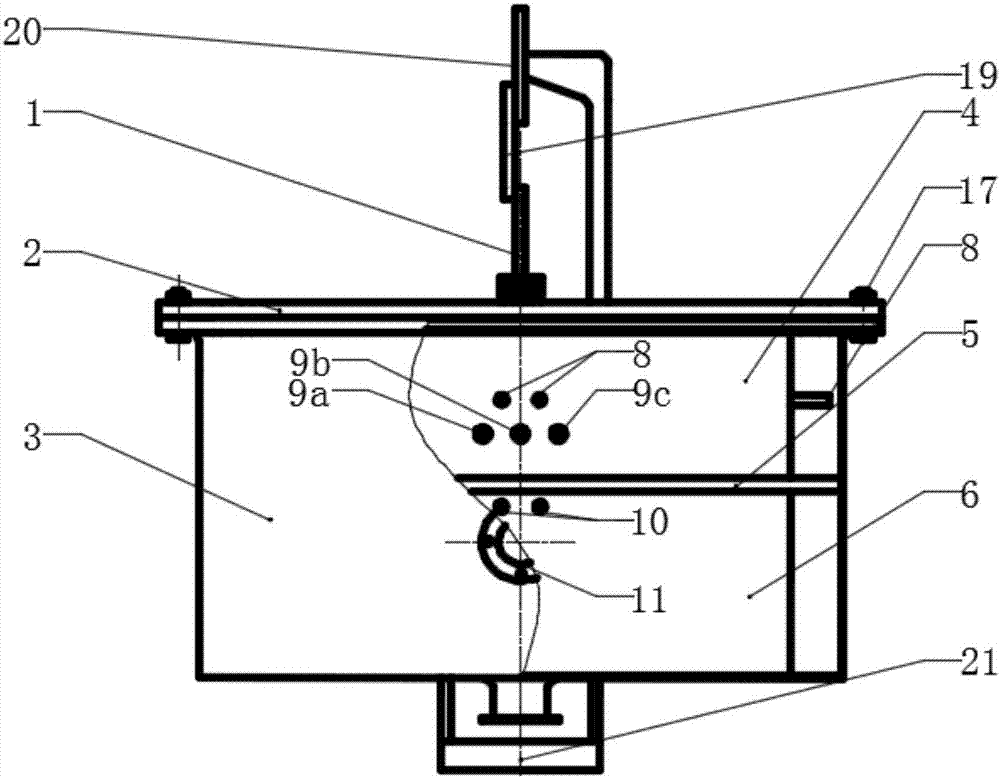

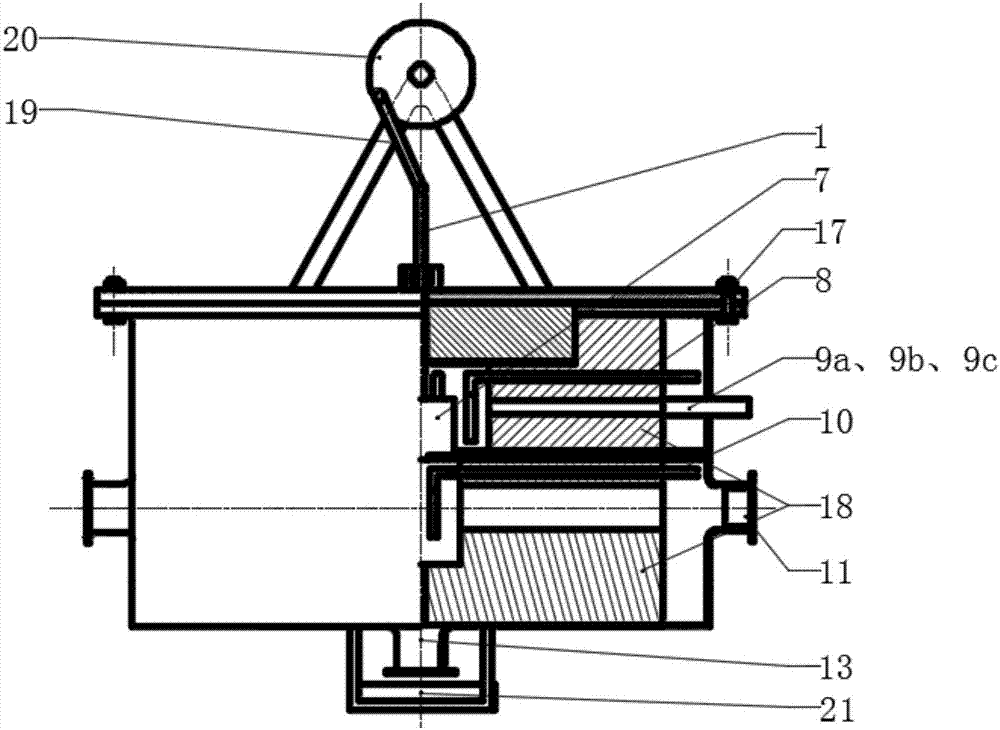

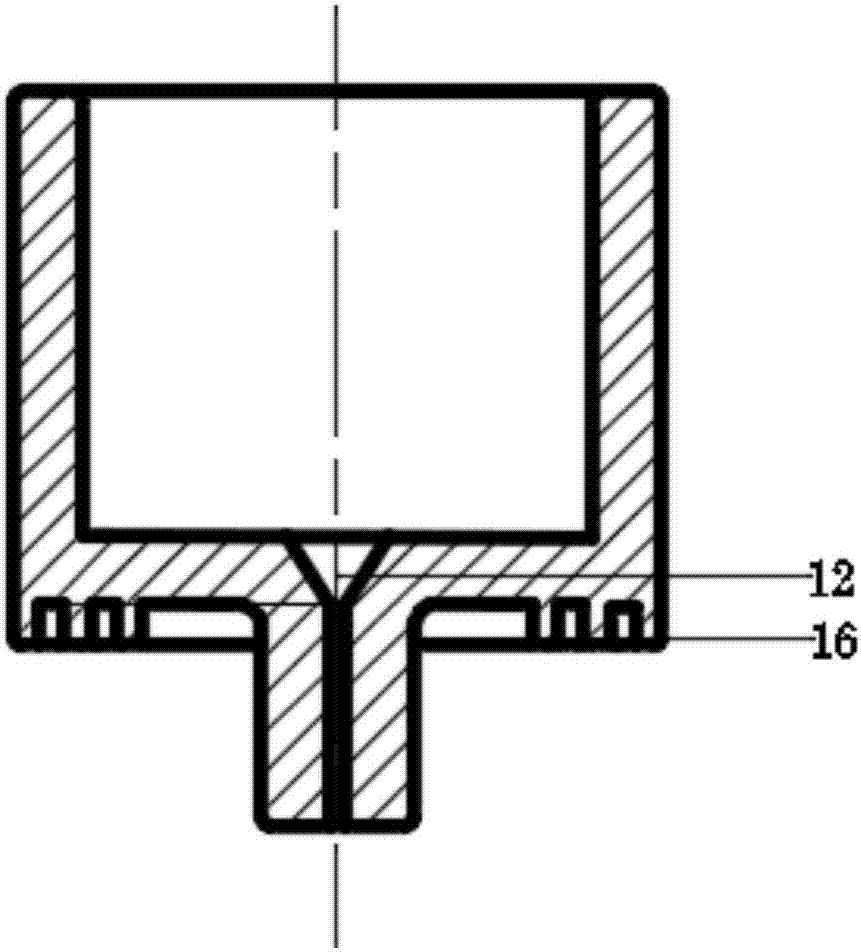

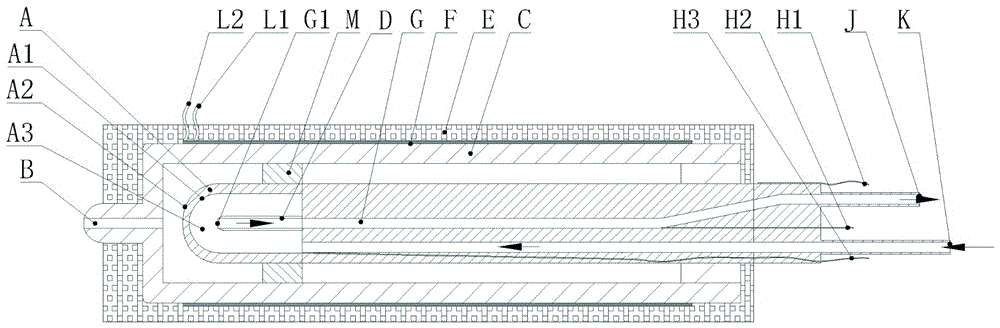

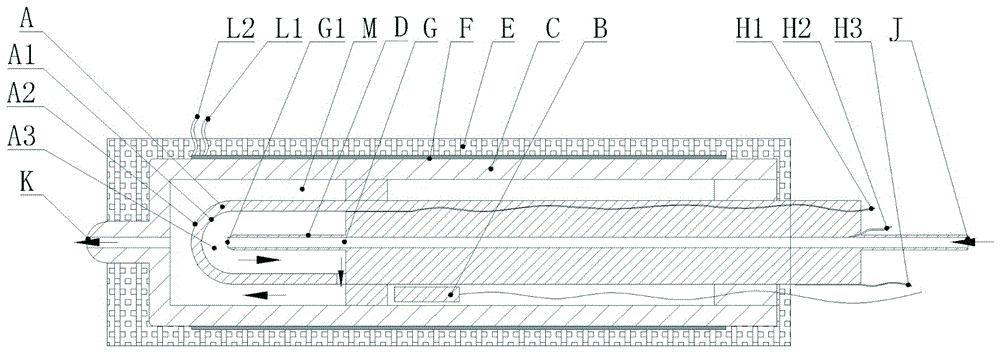

High-temperature melt granulation smelting furnace

ActiveCN107300324AMaintainance of heating chambersCrucible furnacesChemical industryVacuum pumping

Owner:CHONGQING UNIV

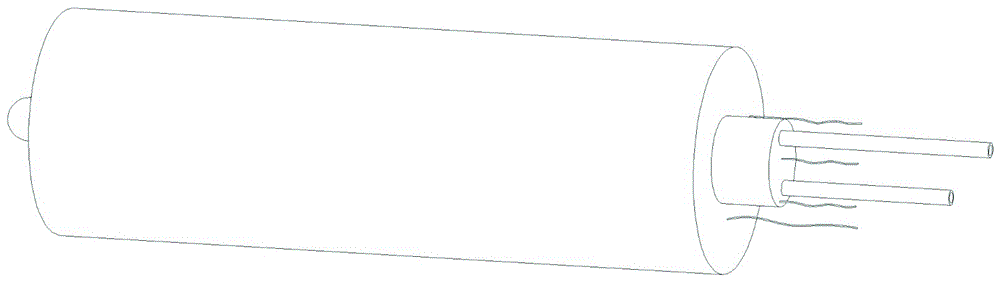

Fire ion detector

PendingCN106841445AAvoid safety hazardsSolve the big problem of difficult monitoringComponent separationChemical industryNitrogen gas

Owner:成都凯圣捷科技有限公司

Method for producing pmida

Owner:赵明贵

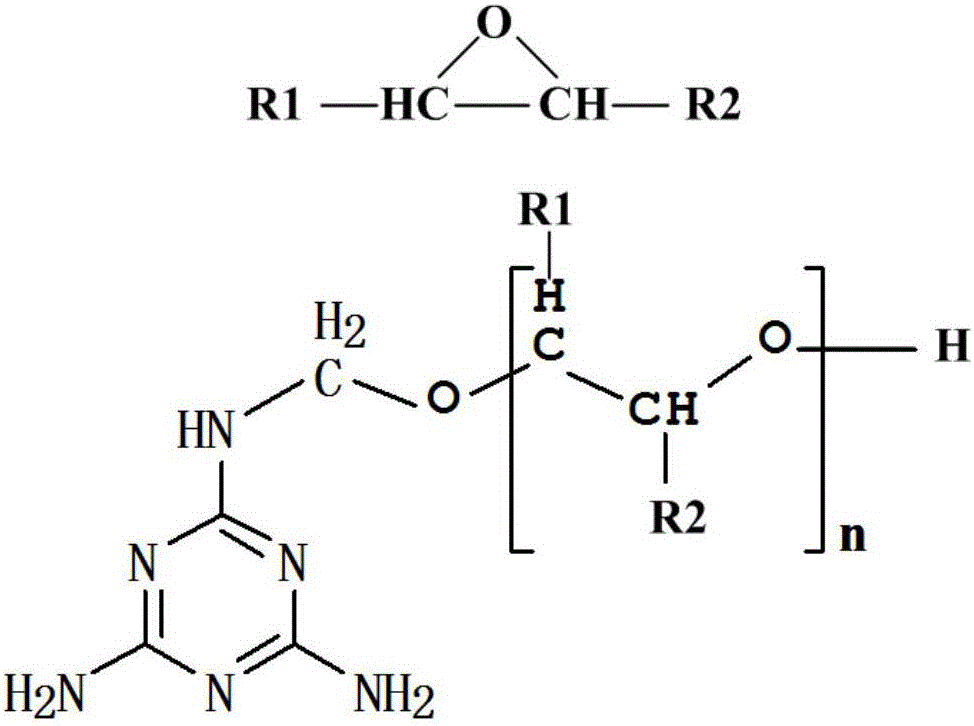

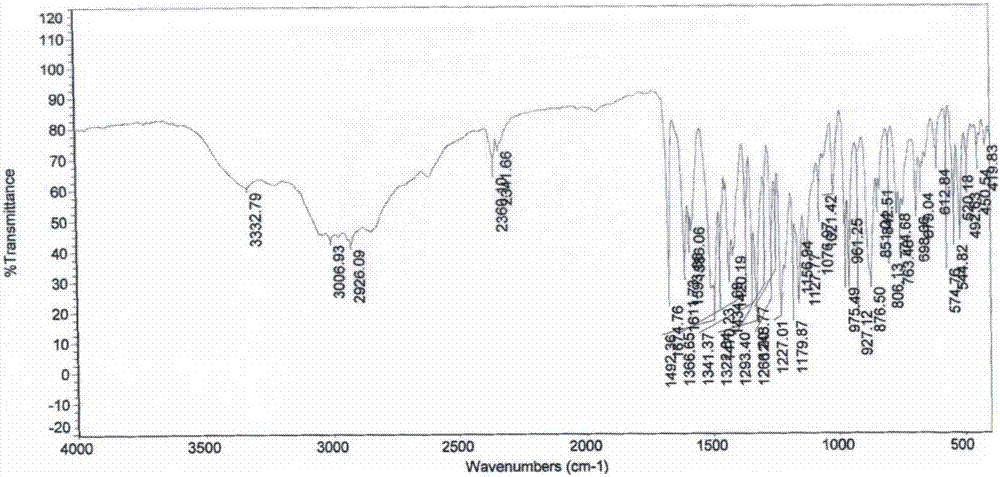

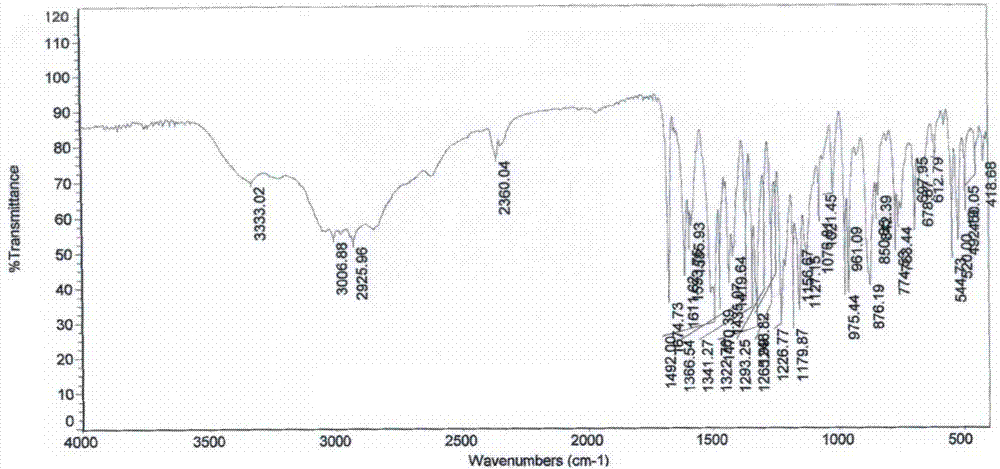

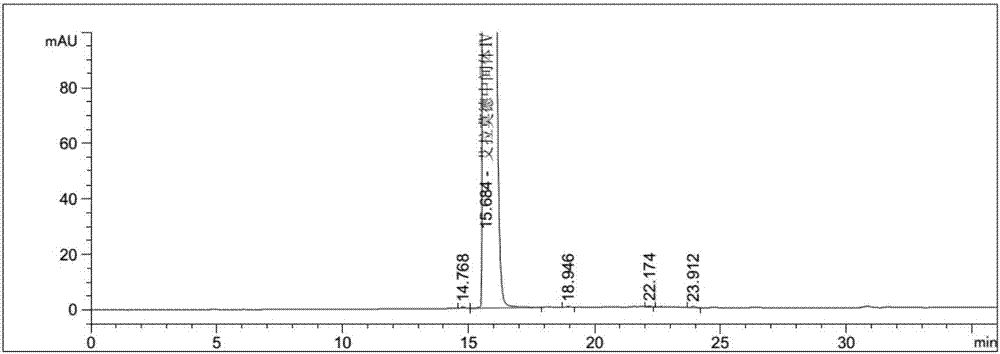

Preparation method of iguratimod intermediate IV

InactiveCN107162942AReduce harmReduce pollutionSulfonic acid amide preparationChemical industryNitrobenzene

Owner:常州佳德医药科技有限公司

Impressing mechanism for chemical industry production packaging

ActiveCN113071234AImprove utilization efficiencyAdjust the embossing heightStampingChemical industryElectric machine

The invention discloses an impressing mechanism for chemical industry production packaging. The impressing mechanism comprises a positioning mechanism, a supporting mechanism, supporting baffle plates, adjusting mechanisms, a mounting clamping plate, a guide mechanism, a tooth-shaped belt and a connecting belt pulley, wherein the supporting baffle plate for supporting is fixedly mounted on the upper end surface of the supporting mechanism, and the adjusting mechanisms used for guiding are symmetrically and rotationally clamped to the inner end faces of the supporting baffles. By arranging the positioning mechanism and the supporting mechanism, when various products and goods are impressed, a connecting motor can provide enough power for the adjusting mechanisms through cooperation of a limiting gear and a connecting tooth groove to drive the positioning mechanism to move up and down in the supporting mechanism, and power can be provided for the supporting mechanism through the tooth-shaped belt pulley to convey various product goods, and the power utilization efficiency of the device is effectively improved.

Owner:ANHUI KAIZE NEW MATERIAL CO LTD

Chemical industry raw material placing barrel

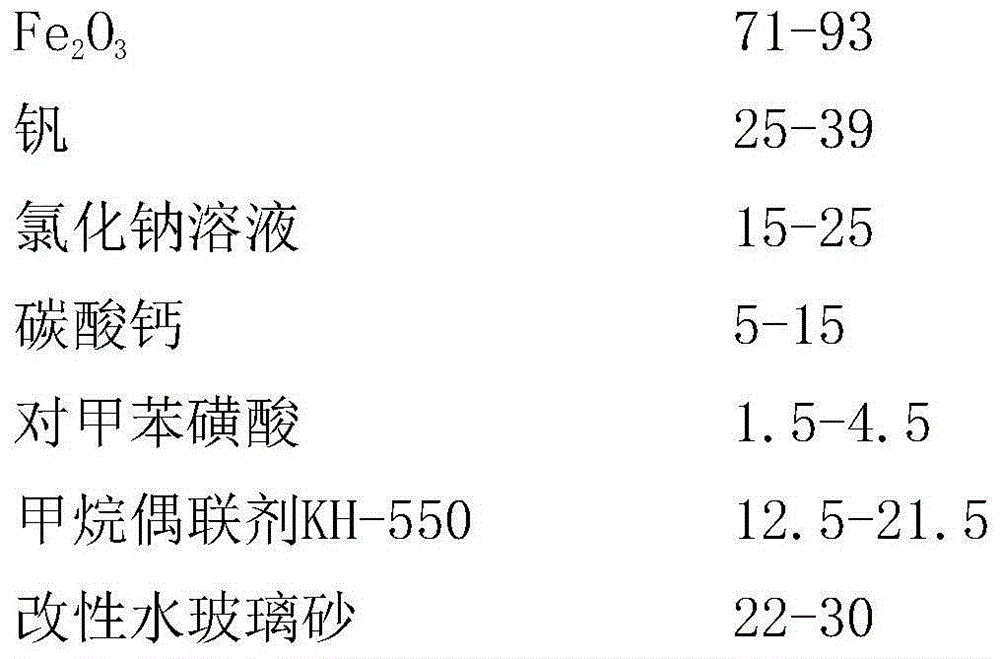

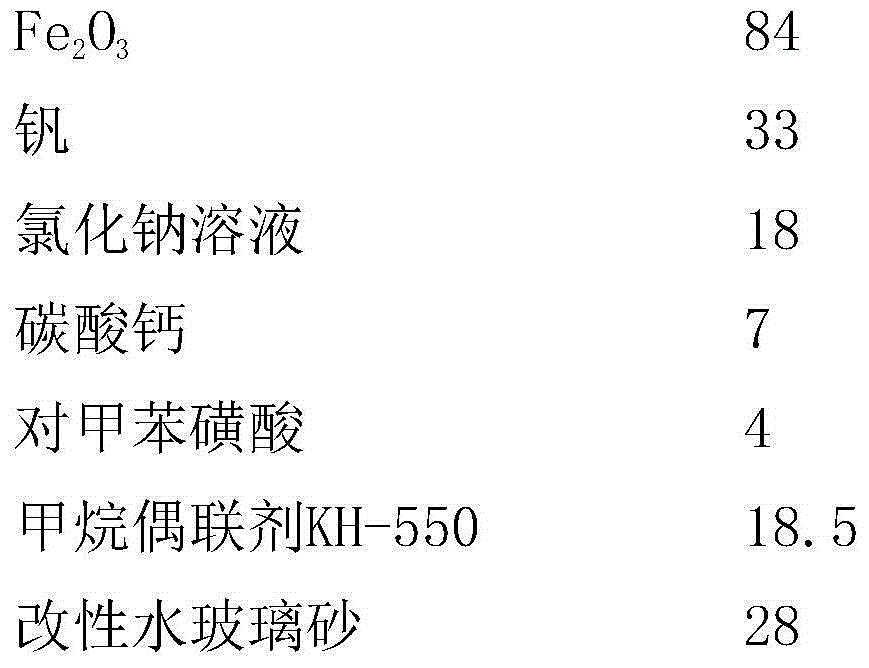

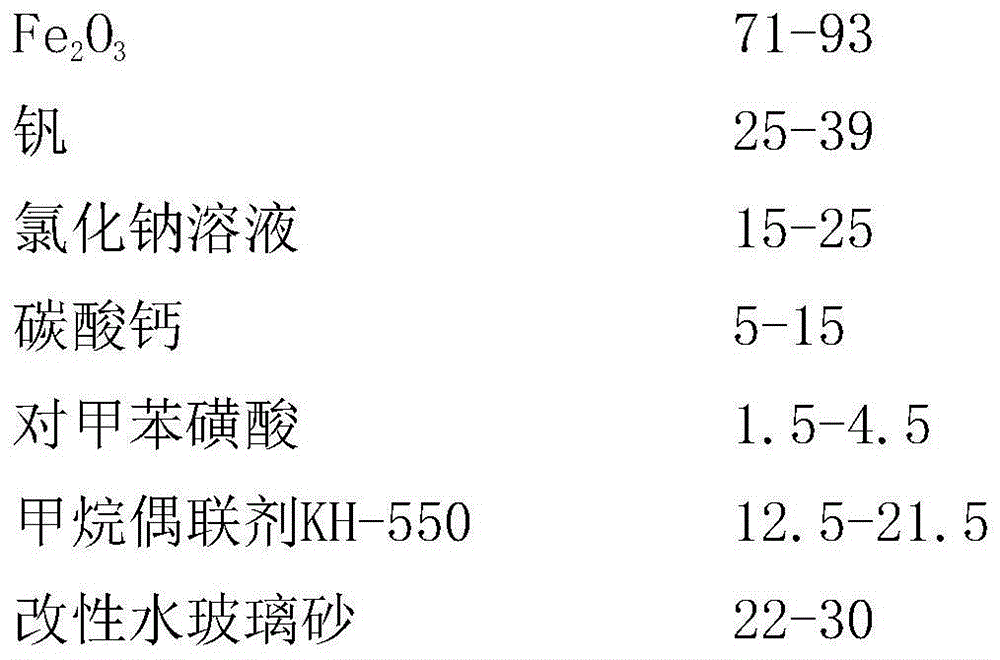

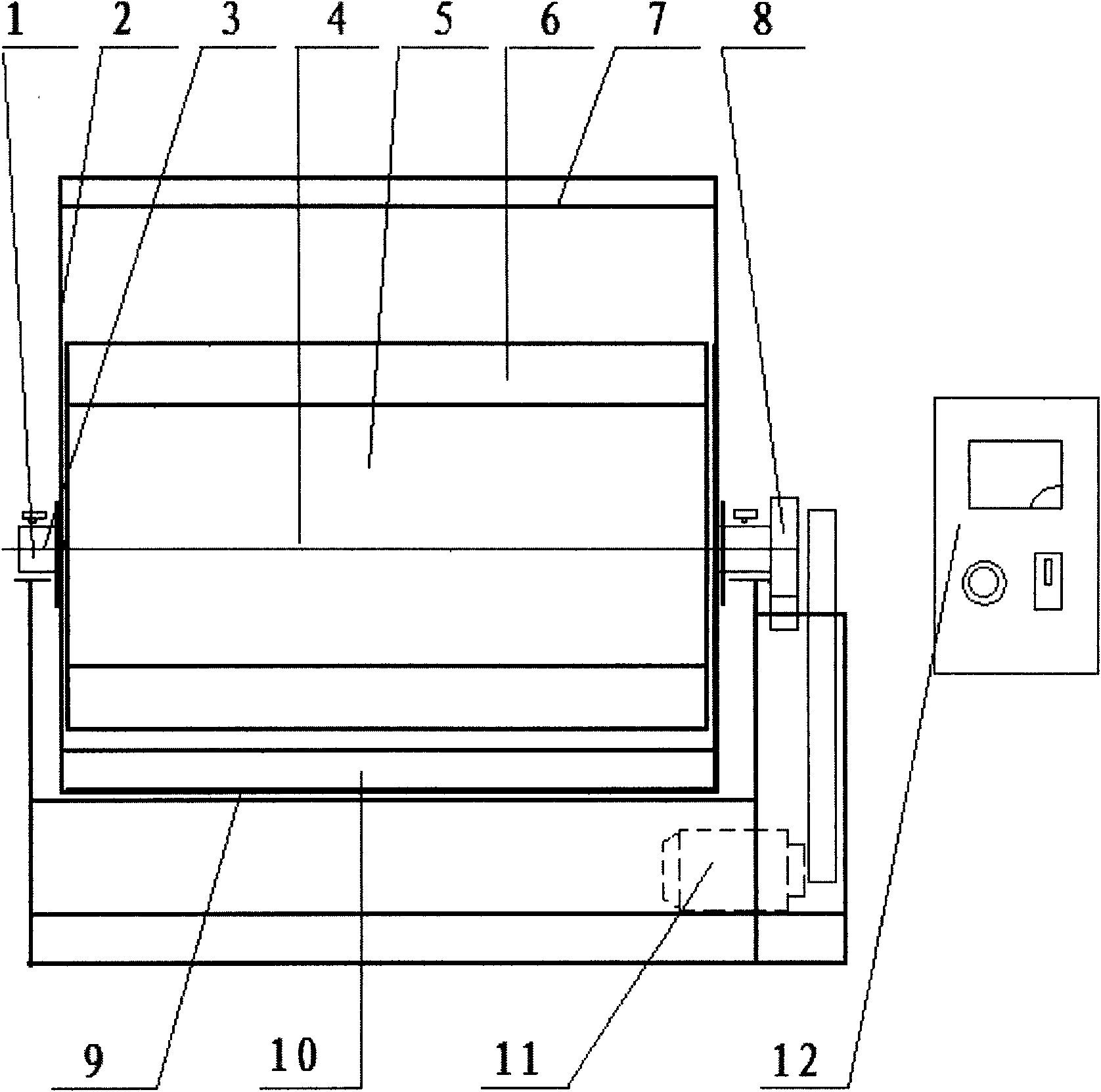

InactiveCN104911433AImprove chemical performanceLow pricePackaging corrosive chemicalsChemical industryCoupling

Owner:含山县宏记精工铸造厂

Multifunctional integrated machine

InactiveCN101987304AReasonable structureEasy maintenanceChemical industryGrain treatmentsChemical industryMotor drive

Owner:原平彤

Foam hand sanitizer with coriander extract as fishy smell removing component and preparation method of foam hand sanitizer

PendingCN114344204AMeet decontaminationGood effect of removing fishy smellCosmetic preparationsToilet preparationsBiotechnologyChemical industry

Owner:南风化工(运城)集团有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap