Chemical industry raw material placing barrel

A technology for chemical raw materials and barrel placement, which is used in the packaging of corrosive chemicals, harmful substances, and types of packaging items. The effect is not high and the chemical properties of the product are excellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below.

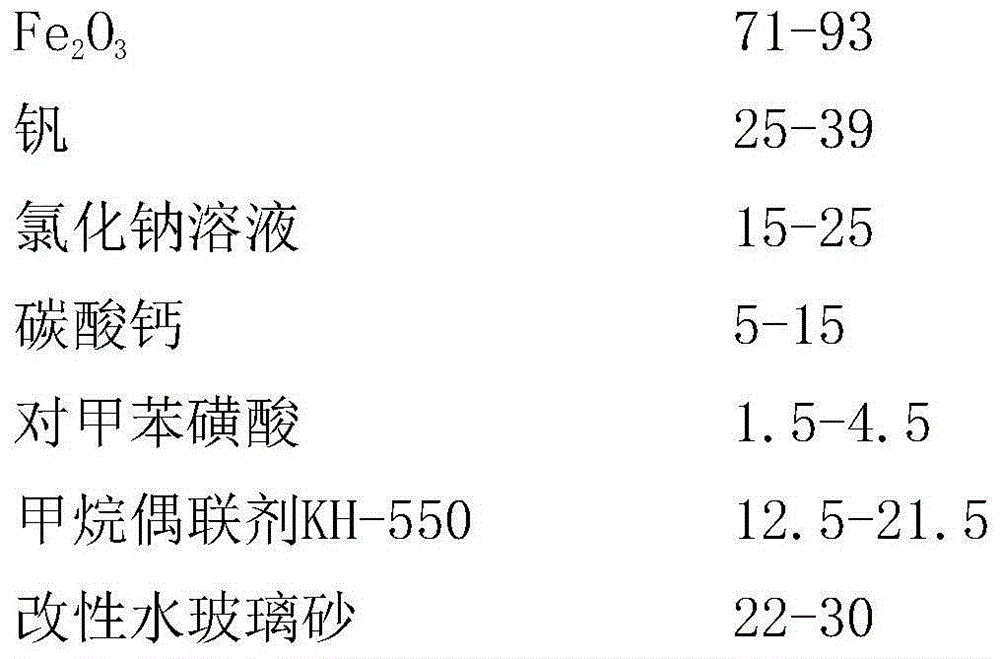

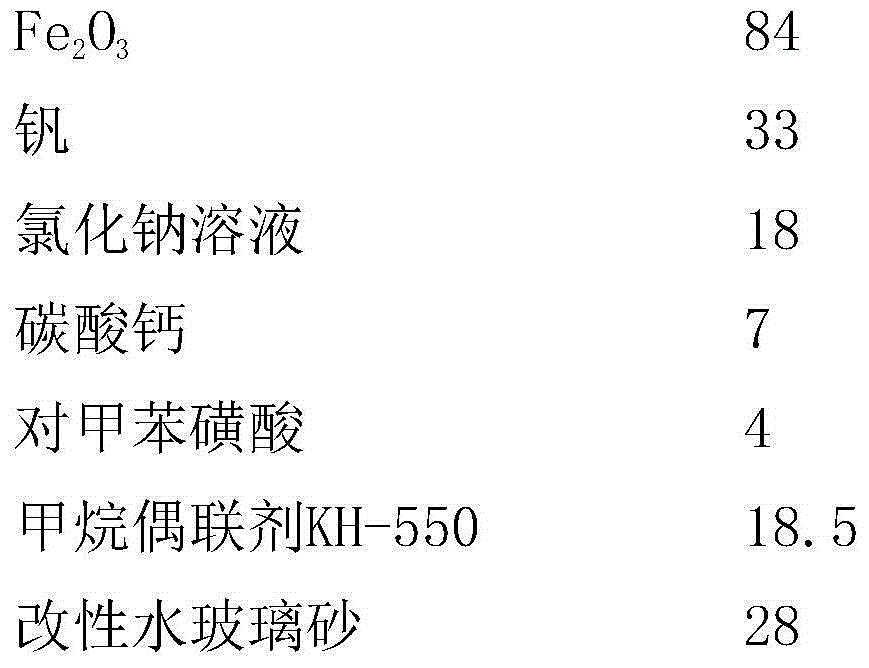

[0017] A chemical raw material storage barrel, which is characterized in that: the distribution ratio of each group is as follows in weight fraction,

[0018]

[0019] A method for preparing chemical raw material storage barrels includes:

[0020] Ⅰ Make models and runners as needed, and add Fe 2 O 3 And vanadium melted into liquid;

[0021] Ⅱ Mix the liquid in Ⅰ and add p-toluenesulfonic acid, and stir, then put it into the baking equipment for high temperature heating, the temperature is 321-431 ℃, the time is 1.5 hours, and the baking time is 1.1 hours. Add calcium carbonate;

[0022] Ⅲ Pour the above-mentioned heated materials into the runner with model, and add modified sodium silicate sand at the same time;

[0023] Ⅳ Put the finished material of Ⅲ into the condensing room at a low temperature of 0

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap