Mining area coal bunker concrete preparing system and coal bunker building method

A technology for making a system and concrete, which is applied to clay preparation devices, chemical instruments and methods, mining equipment, etc., can solve the problems of long time for concrete dumping, discontinuous transportation, low winch efficiency and safety, etc., and achieves good continuity, The effect of reducing the transfer link and ensuring the construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

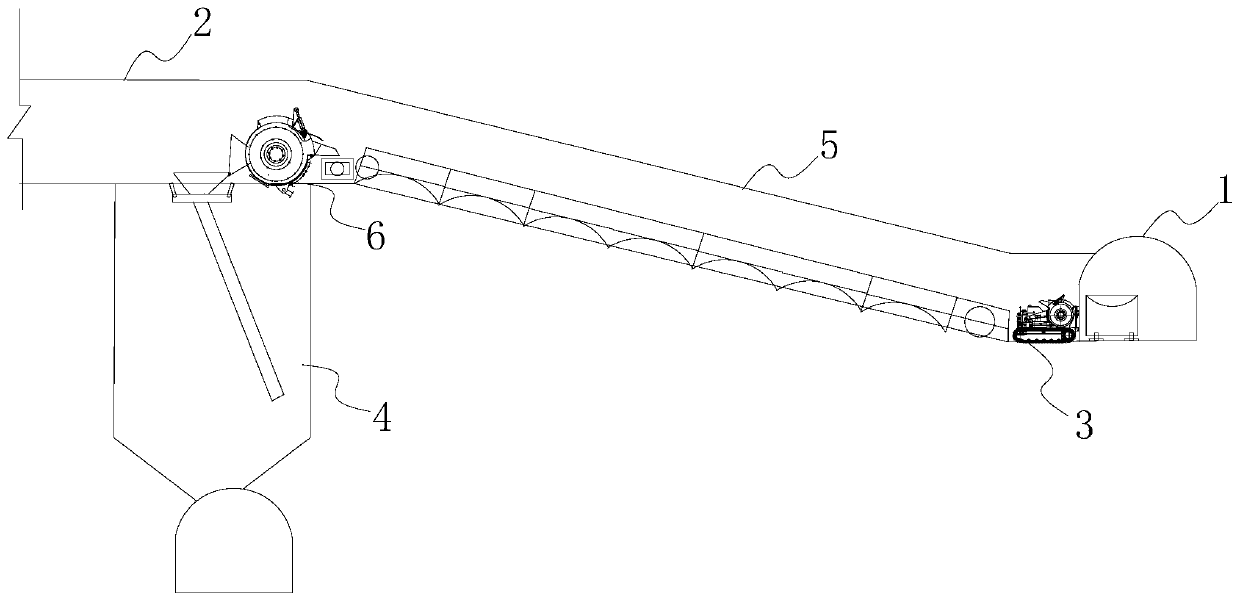

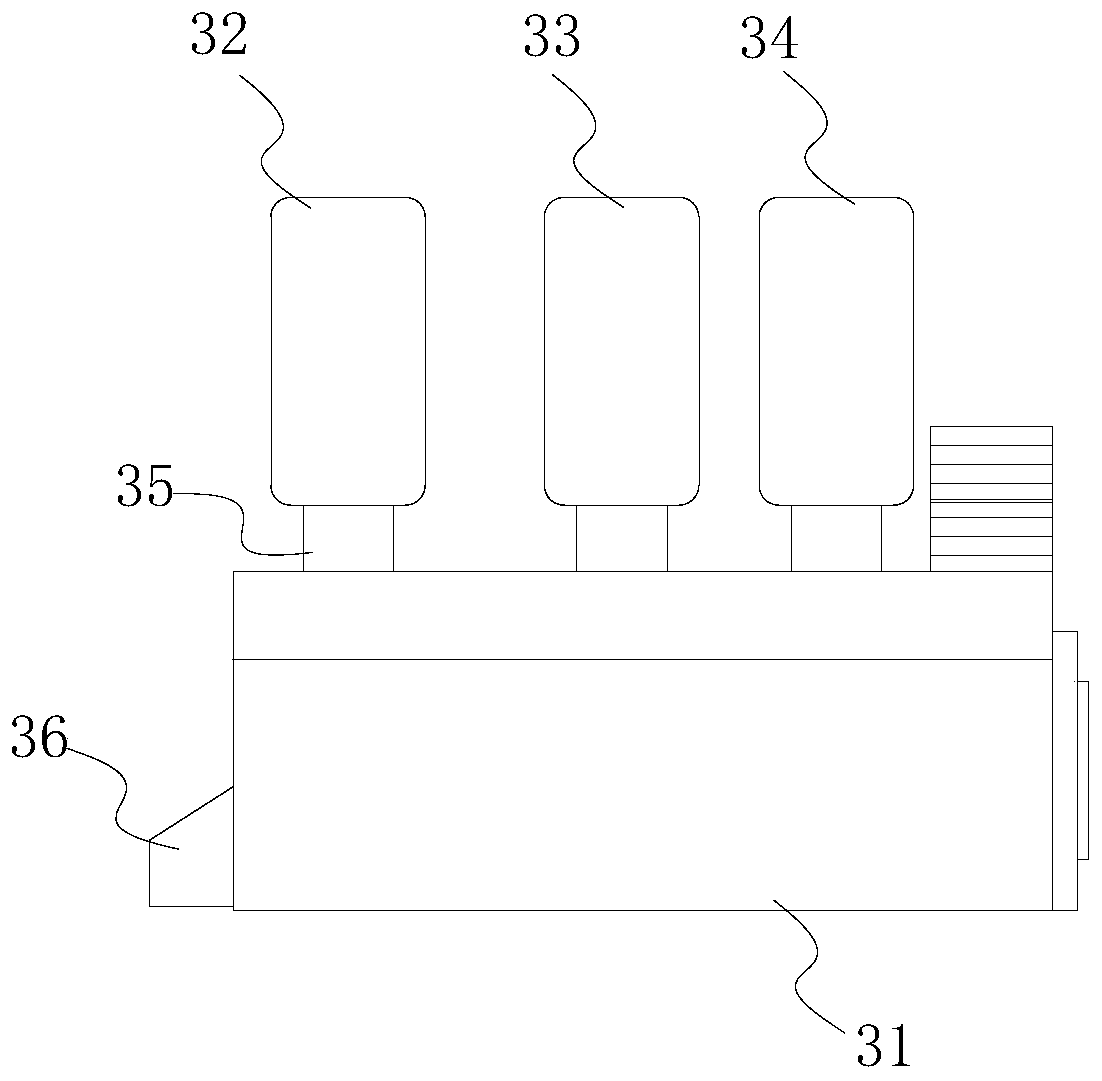

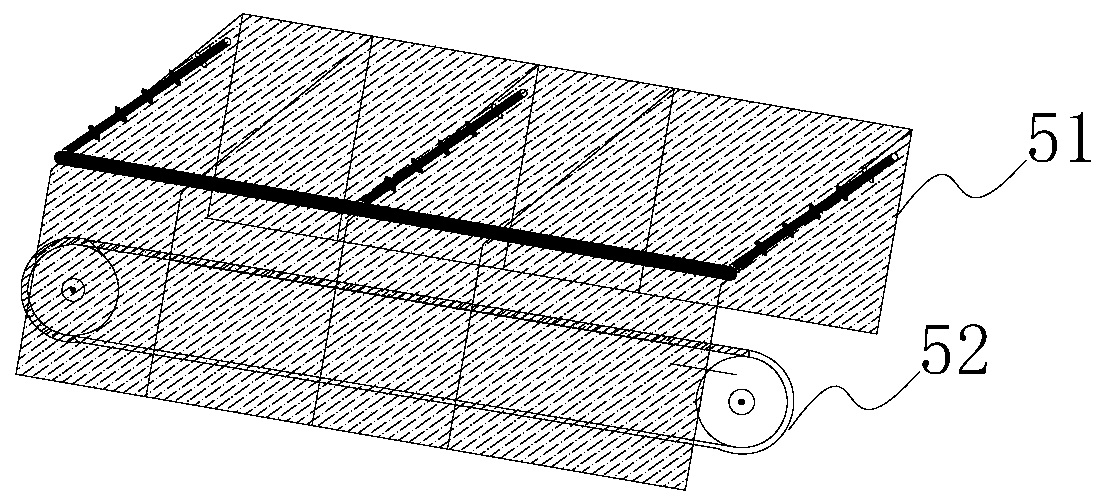

[0029] combine Figure 1 to Figure 6 As shown, a coal bunker concrete production system and a coal bunker construction method in the mining area provided by the present invention are implemented in the following manner.

[0030] A coal bunker concrete production system in a mining area specifically includes a material transportation road 1, a belt transportation road 2, an aggregate chamber 3, a coal bunker 4, a mining area connecting road 5 and a mixing chamber 6. The system ensures the continuity of the concrete proportioning, conveying and mixing process through the reasonable setting of material transportation lane 1, belt transportation lane 2, aggregate chamber 3, mining area connection lane 5 and mixing chamber 6. And the reloading link is reduced, especially the materials with good ratio are directly sent to the mixing chamber 6 for mixing, which realizes the continuous production of concrete. Among them, the aggregate chamber 3 is set in the material transportation road

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap