Seedling dropping device and seedling dropping method

A monitoring device and a technology for loading seedlings, which are applied in planting methods, applications, agriculture, etc., can solve the problems of inability to effectively control the angle of seedlings, the separation of seedlings and seedlings, affecting the continuity of seedlings, and achieve a simple and reliable structure. , compact structure, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0042] Example 1

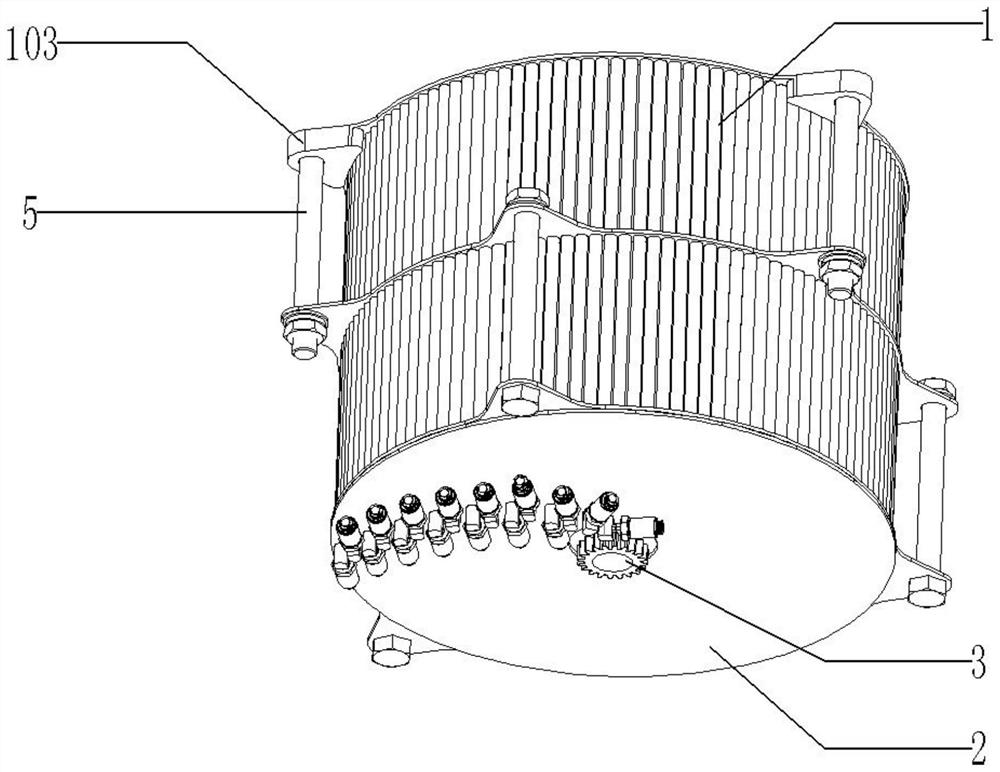

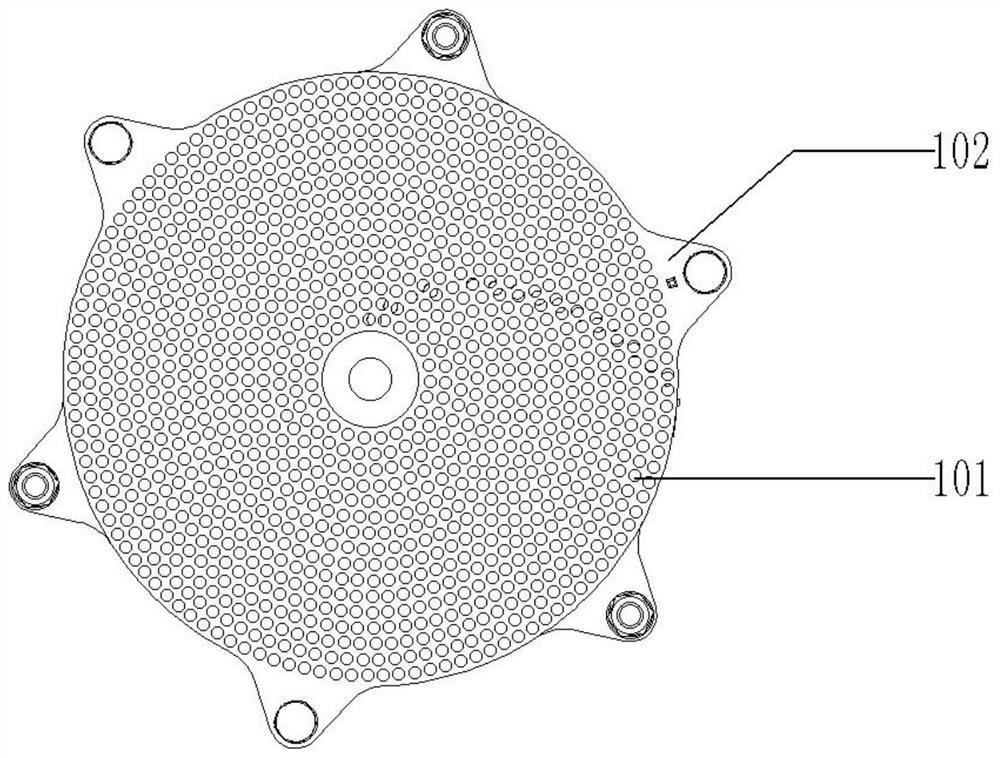

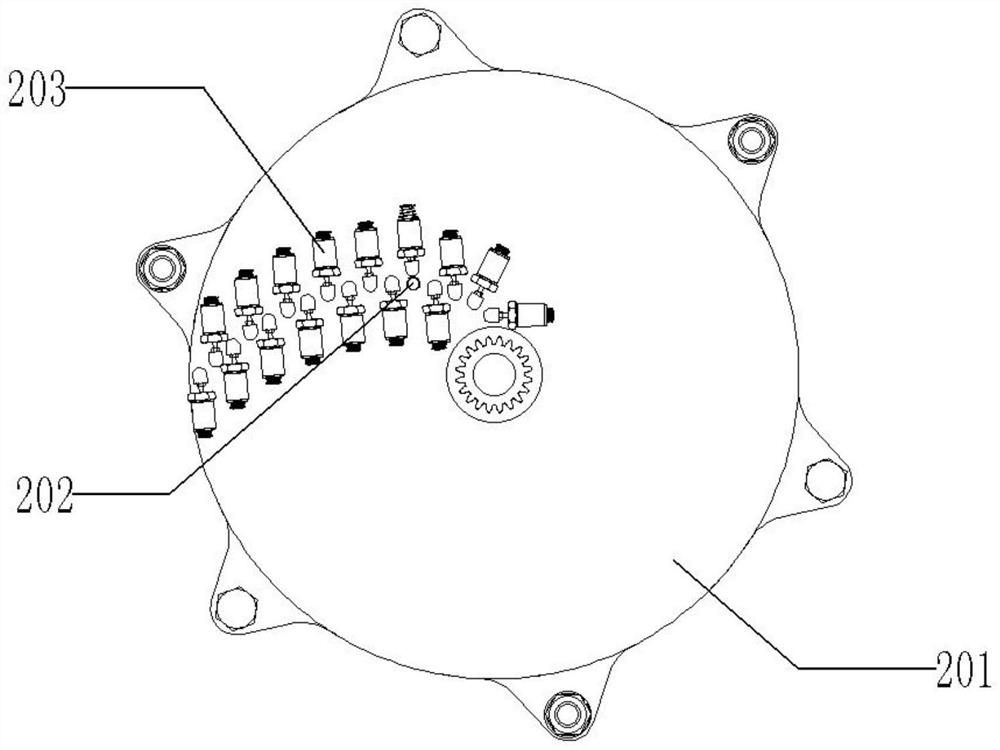

[0043] A seedling device, such as Figure 1-4 As shown, including the femoral container 1 and the seedling unit 2; the seedling container 1 includes a rotating shaft and a plurality of propelinated portions 101 for loading a single seedling, the rotating shaft being provided in the center of the femoral container 1, and multiple locations In the present embodiment, the plunger portion 101 is arranged to form a multi-circle layer structure, in the present embodiment, the number of circles is sixteen, the number of circles can be set according to the actual working condition; the seedling unit 2 includes a bottom plate 201 and a plurality The villary port 202 that matches the voyage portion 101, the bottom plate 201 is rotatably coupled to the femoral container 1, and the plurality of the exit port 202 is disposed in the bottom plate 201, and arranged in accordance with the circle layer structure of the seedling portion 101. The number of seedling port 202 matches the

Example Embodiment

[0050] Example 2

[0051] Method for seedling equipment, such as Figure 1-4 As shown, including the following steps:

[0052] Seedling steps: into each of the seedling container 1 into the seedling portion 101;

[0053] Driving step: By driving the loaded container 1 by the driving unit 3, the bottom plate 201 is fixed, the bottom plate 201 is fixed; the monitoring step: the seedling monitoring device collects the number of turns of the seedling container 1 in real time and the rotational angle data, and transmits to the seedling control system;

[0054] Permanent step: The seedling control system determines the rotational position of the vital portion 101 in accordance with the results of the seedling monitoring device, and when it is determined that the seedling container 1 is rotated to the semifinal port 202 of the bottom plate 201, the seedling control The system control transmits a control signal to the corresponding open-door mechanism 203, and the control opening mechanism 20

Example Embodiment

[0058] Example 3

[0059] Example 3 is a further improvement of Example 2; the number of innermost plug-in filming portions 101 is X (X can be different depending on the working condition), and the number of inwardly adjusted second circles 101 is 2X. The number of three-circle sprigper portion 101 is 3X from the inside outward, so that this is pushed. When the continence of the most inner ring, the exterior port 202 corresponding to the innermost plunger 101 is always opened, and the remaining fifteen emerging ports 202 are closed. After the femoral container 1 is rotated, the innermost plunger will be completed. After the first circle seedlings were passed, the outlet 202 corresponding to the first circle seedlings was closed. At this time, due to the number of pieces of the second circle of the seedling portion 101, the speed ratio of the drive unit 3 drives the container 1 is constant, so The angular velocity of the second loop is twice the first circle, that is, the 2X seedling

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap