Isolation drainage heating stirrer

A technology for heating, stirring and isolating blocks, which is used in mixer accessories, transportation and packaging, mixers, etc., can solve the problems of inability to achieve the isolation function of medicinal liquid, inability to effectively eliminate volatilization of medicinal liquid, and inability to control the step-by-step addition of medicinal liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

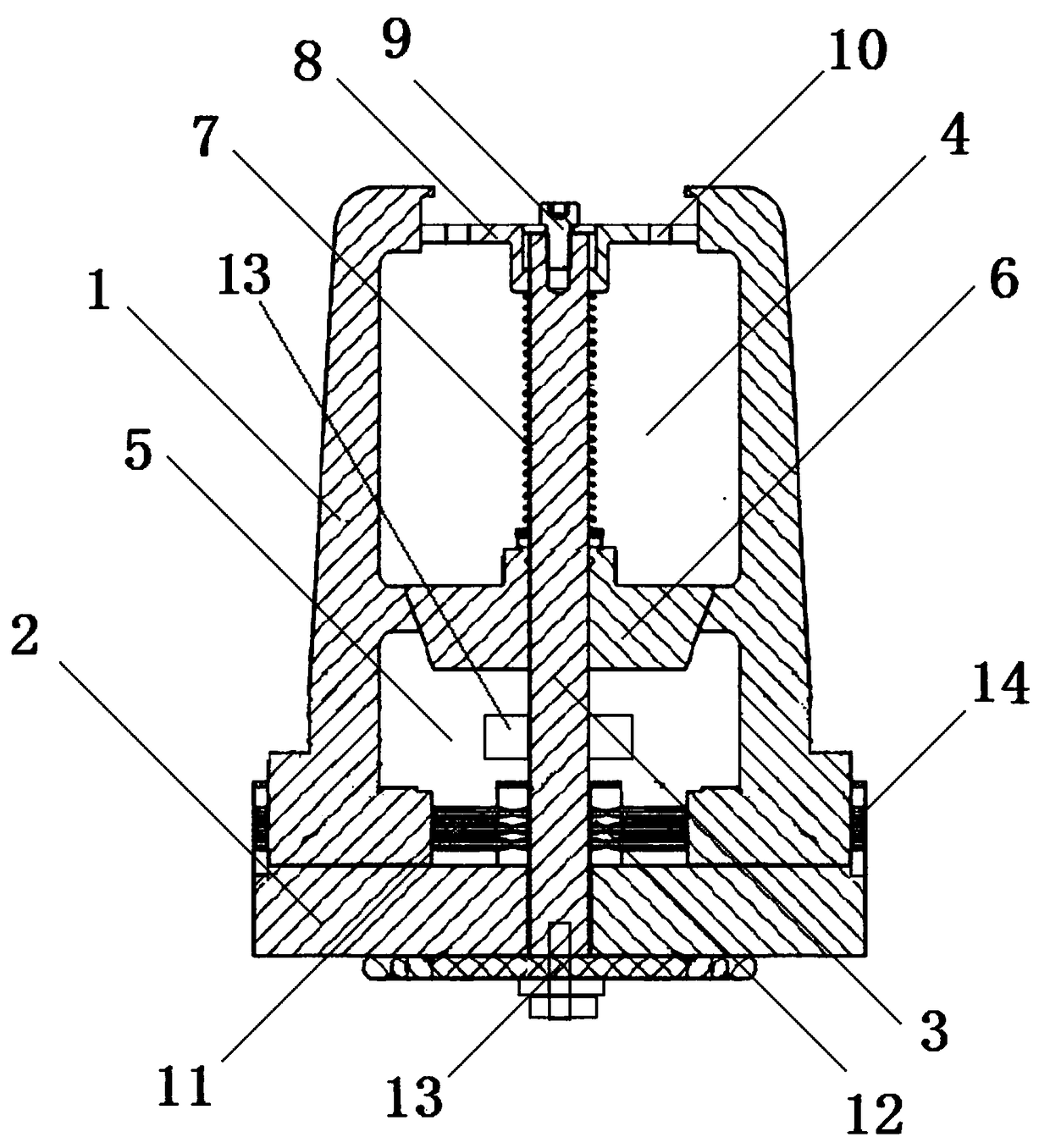

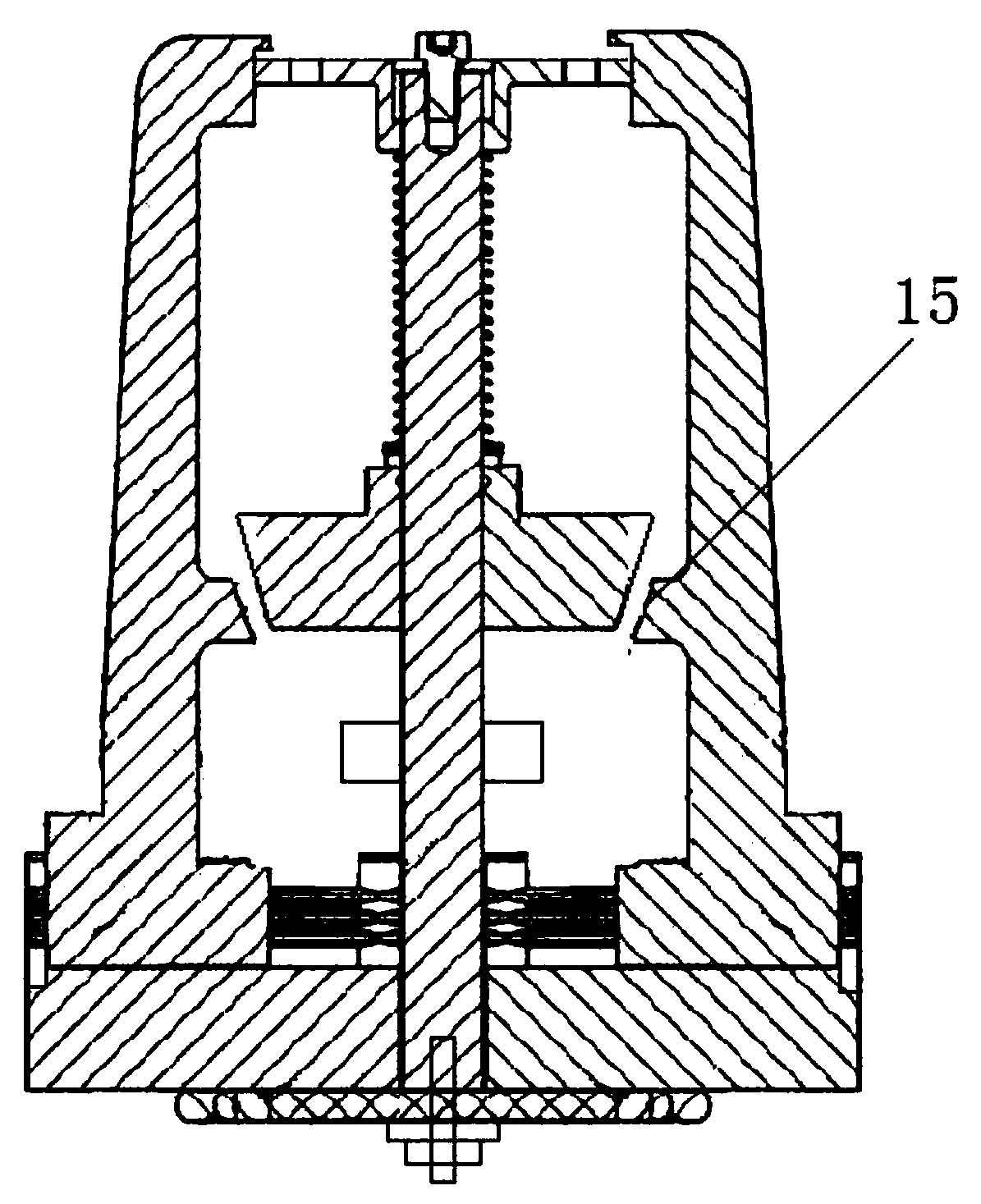

[0019] Such as figure 1 and figure 2 As shown, the present invention is an isolation and drainage type heating and stirring device, including a housing 1, a base 2, a pressing actuator cover 8 and a heater 13, the bottom end of the housing 1 is arranged on the base 2, and the pressing actuator cover 8 is embedded in the The top of the housing 1 and the interior of the housing 1 are sequentially provided with a drainage chamber 4, a drainage isolation chute 15, and a mixing chamber 5 from top to bottom, and the drainage chamber 4 is connected to the mixing chamber 5 through the drainage isolation chute 15 Generally, the inner center of the housing 1 is also provided with a longitudinal mandrel 3,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap