Wet nanometer grade vortex dust-removing device and dust removing method

A dust removal device and nano-level technology, which are applied in the directions of combination devices, separation methods, chemical instruments and methods, can solve the problems of unsatisfactory dust removal effect and inability to achieve dust removal efficiency, and achieve ideal dust removal effect and improve the effect of dust removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

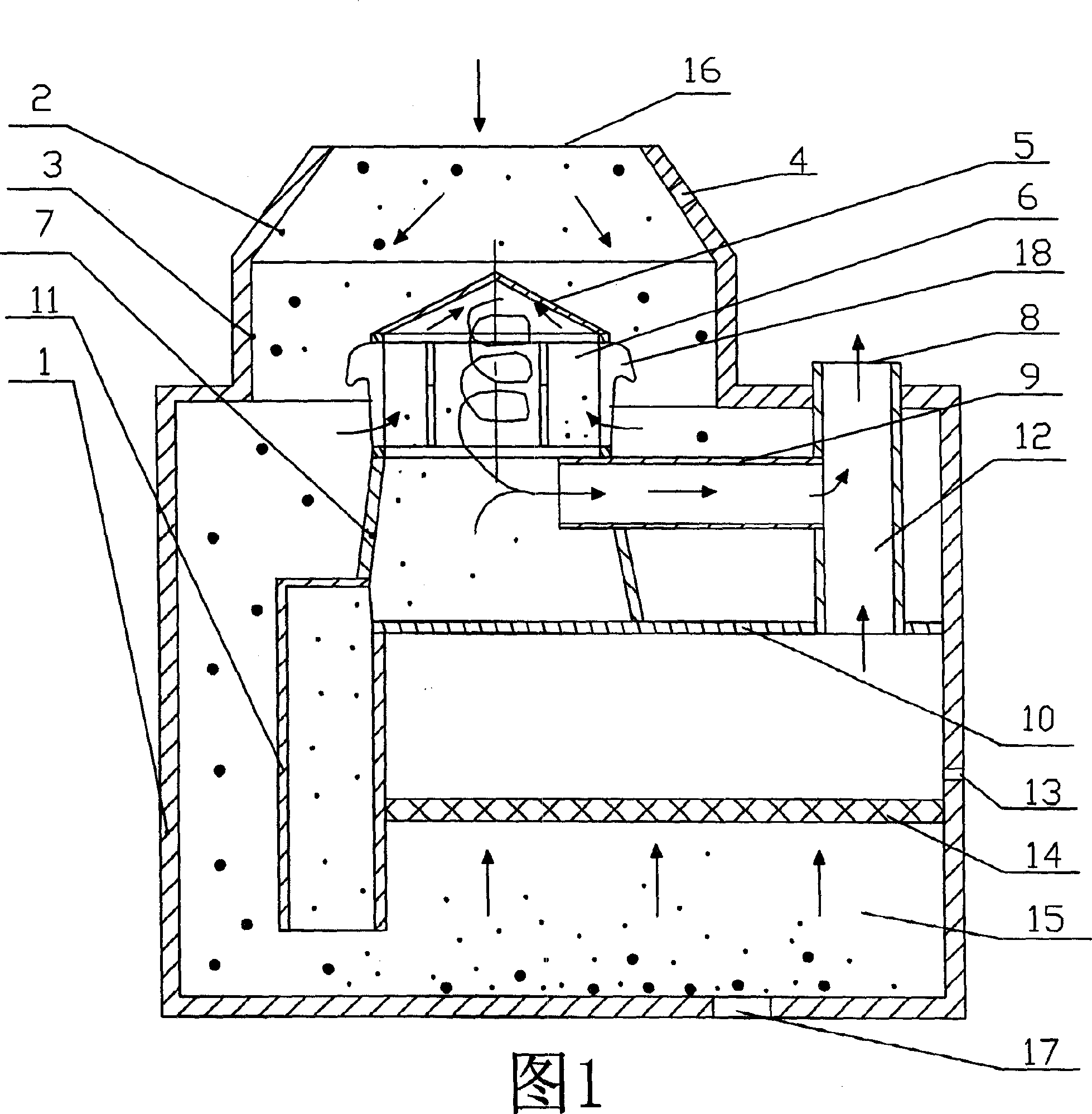

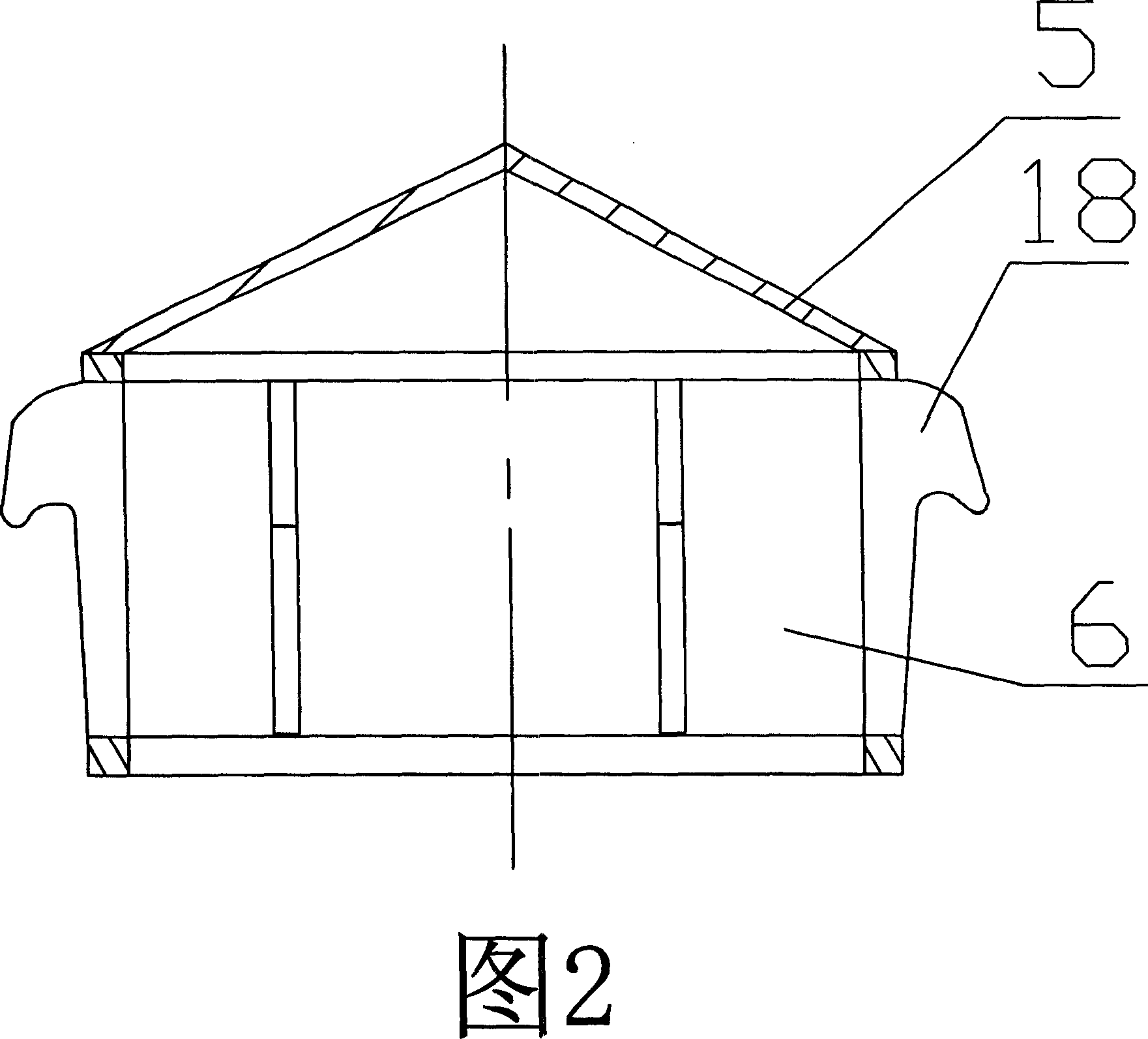

[0043] A wet-type nano-scale vortex dust removal device, the cylindrical furnace body is a stainless steel shell 1, the inner wall of the shell is coated with acid and alkali materials, the height of the furnace body is 160cm, the horizontal diameter is 200cm; the flue gas of the flue liquid mixing chamber 2 on the top of the furnace body The inlet is connected to the smoke and dust input nozzle 16 of the Venturi type equipment. The smoke-liquid mixing chamber 2 is hollow and frusto-conical, with a top diameter of 24 cm, a cone bottom diameter of 40 cm, and a height of 25 cm. The treatment liquid injection nozzle 4 is installed in the chamber On the chamber wall; below the smoke-liquid mixing chamber 2 is a hollow cylindrical smoke-liquid expansion chamber 3 connected to it, with a column diameter of 40cm and a column height of 25cm; installed in the furnace body and located in the flue gas expansion chamber 3 for vortex dust removal The device is composed of a hollow guide cone 5 lo

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap