Jet mill for ultra-fine powder

A technology of jet mill and ultrafine powder, which is applied in grain processing and other directions, can solve the problems that materials cannot meet the requirements of microgrinding and ultrafine powder, cannot adapt to cutting-edge national defense, high technology, etc., and achieve the effect of meeting processing requirements and adapting to technological development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

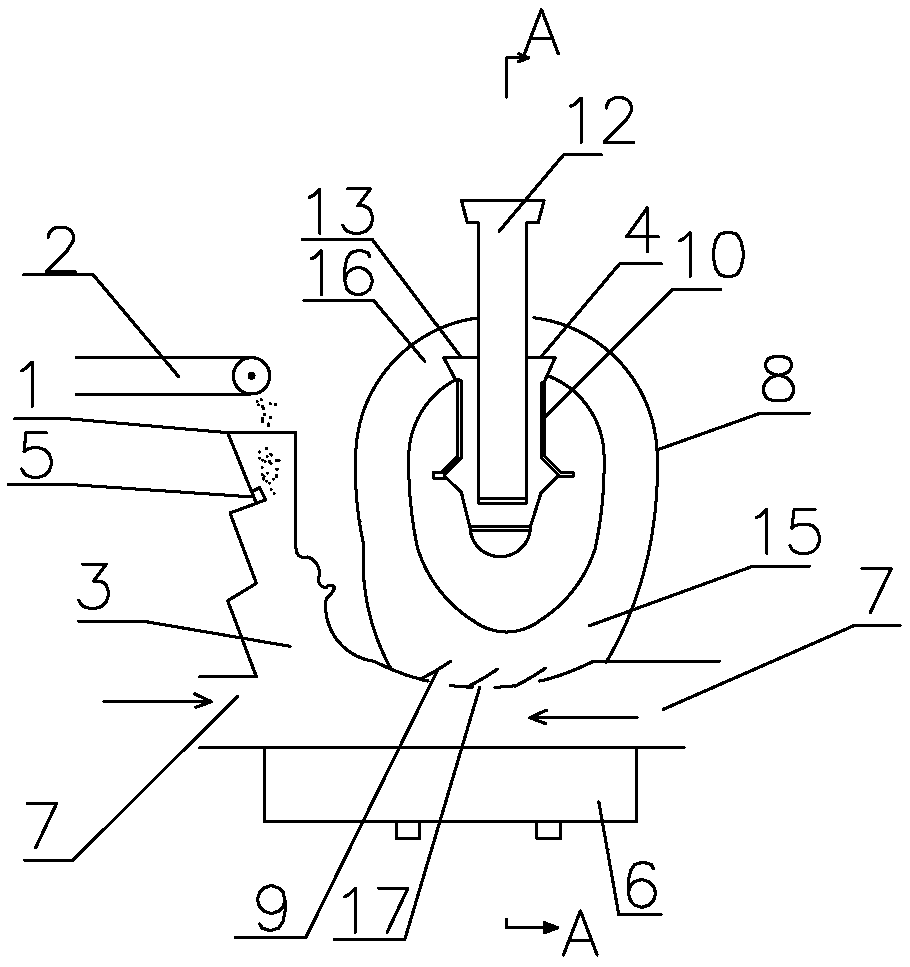

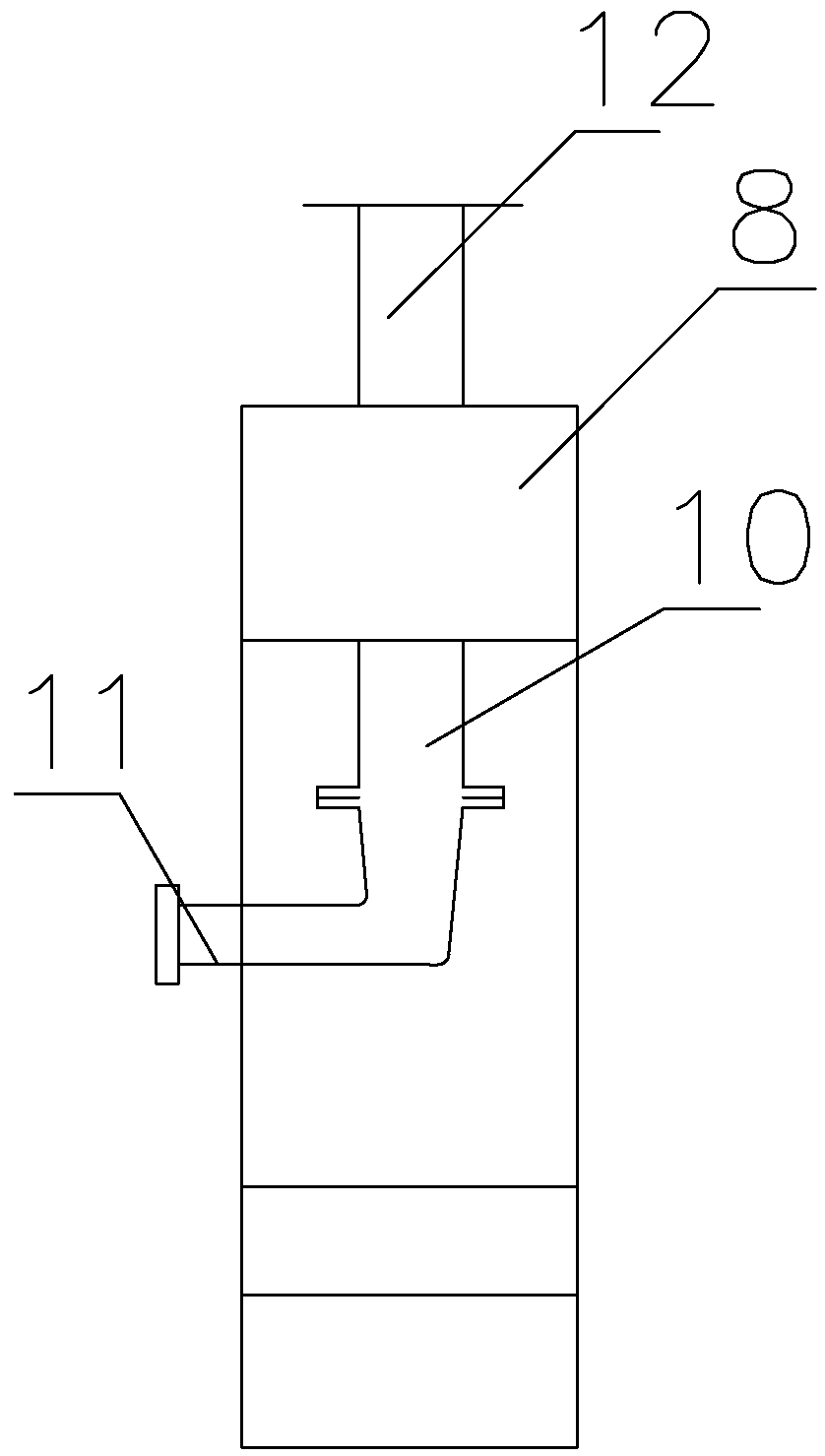

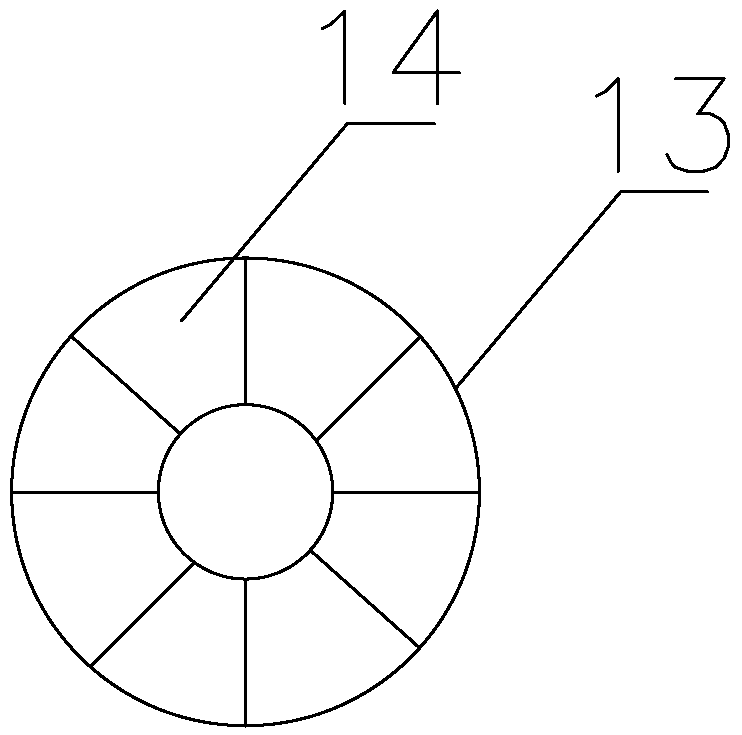

[0013] Such as figure 1 , figure 2 , image 3 As shown, the present invention comprises a hopper 1, a feeder 2, a crushing device, and a classifying device. The hopper 1 is connected with the crushing device through a feedway 3, and the classifying device includes a classifier 4. The entrance of the feedway 3 is provided with an injector 5, and the feedway 3. The bottom is connected with a support box 6, and the support box 6 is provided with an air flow port 7. The crushing device includes a variable-section circulation pipe 8 connected with the material channel 3 and located above the support box 6, and a variable-section circulation tube connected to the material channel 3. The pipe 8 is provided with a nozzle 9, the axis of the spraying direction of the nozzle 9 is tangent to the center line of the variable cross-section circulation pipe 8, and the upper part of the variable cross-section circulation pipe 8 is connected with the classifier 4, and the classifier 4 is connect

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap