Milling insert and a milling insert tool for chip removing machining

a technology of inserts and milling tools, which is applied in the direction of milling equipment, turning tools, milling equipment, etc., can solve the problems of poor service life of tools, and cost-consuming and time-consuming process for making threads in hard materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

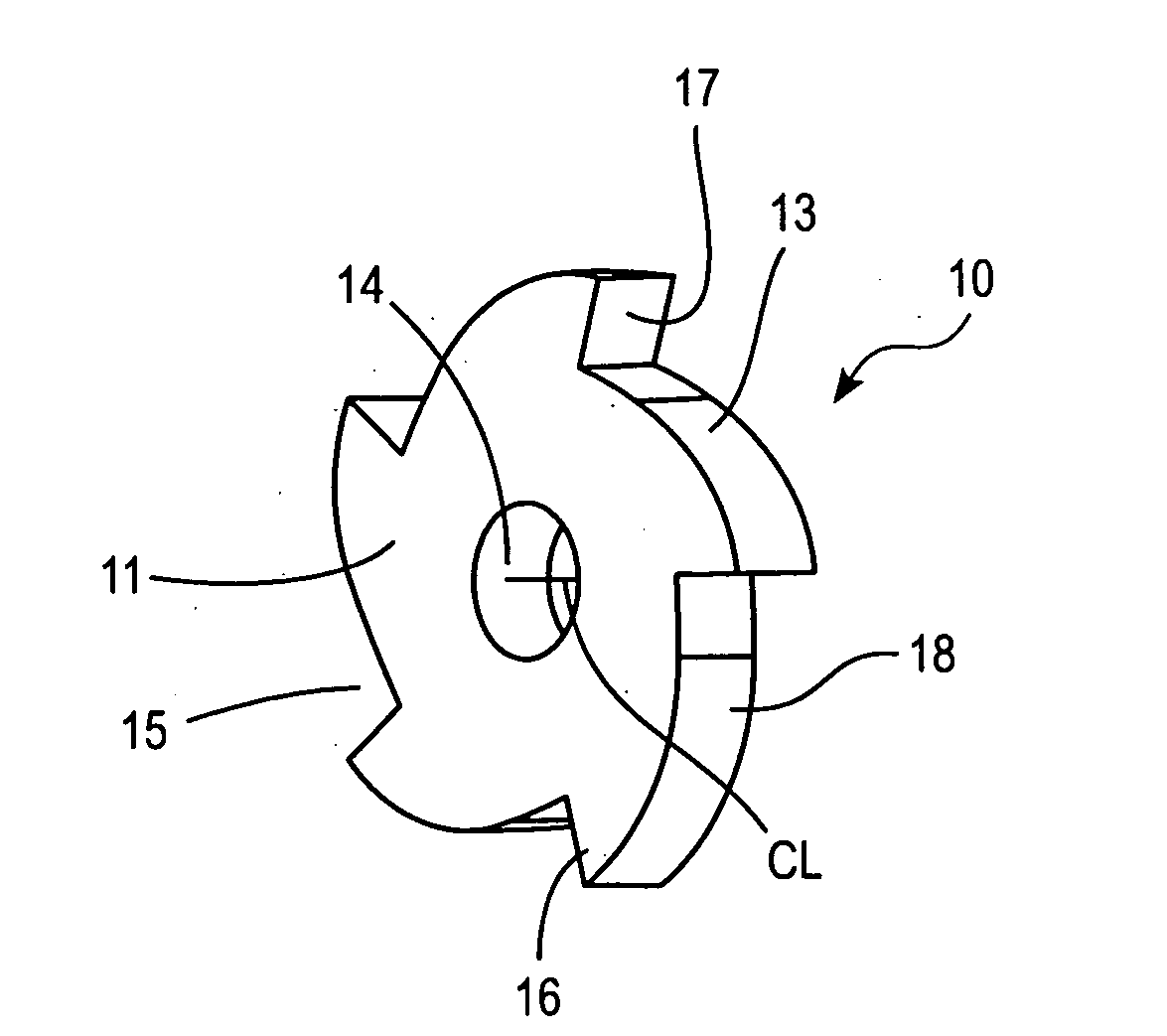

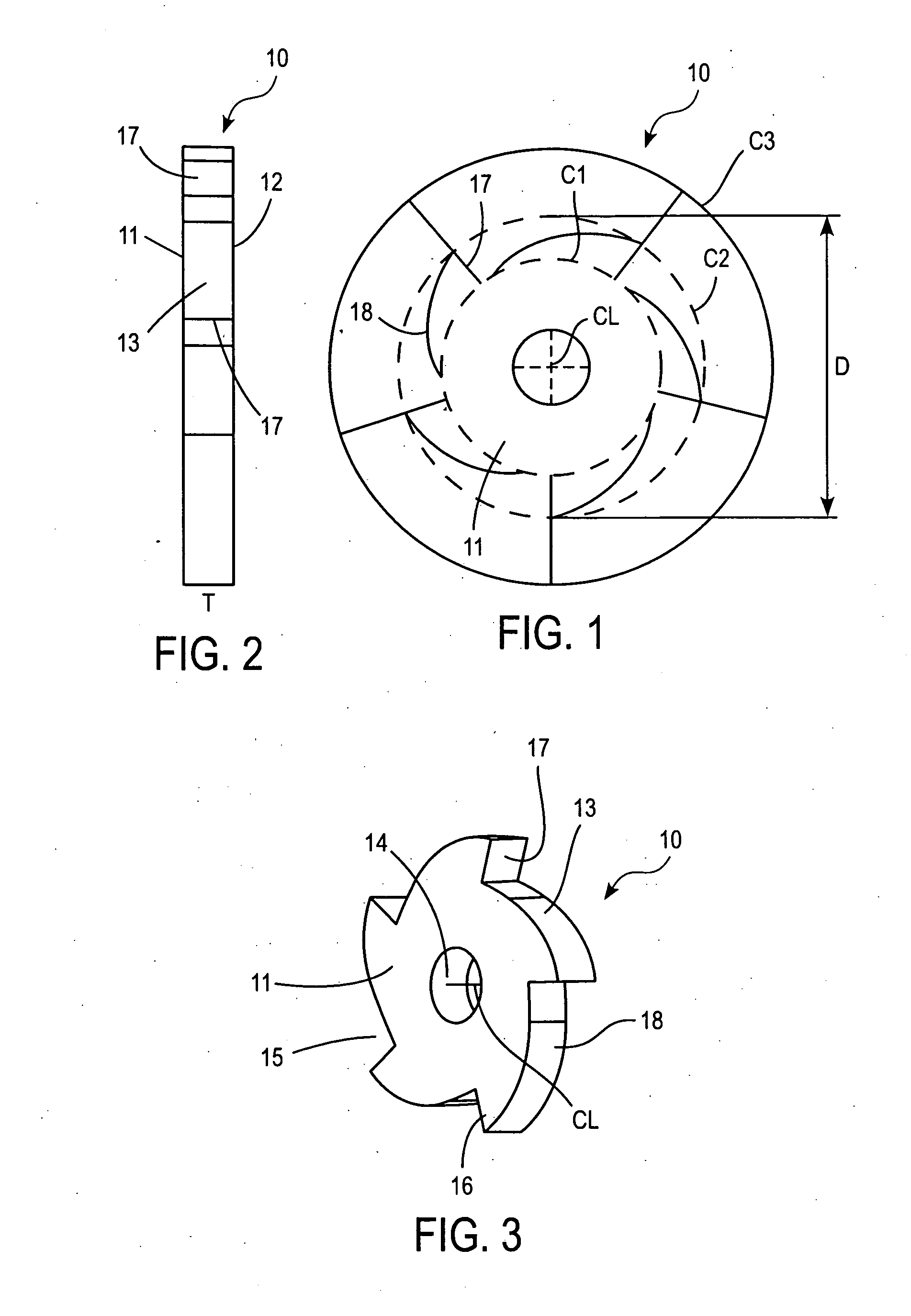

[0017]In FIGS. 1, 2 and 3, a work piece 10 is shown for a milling insert according to an embodiment of the invention. The work piece 10 consists exclusively of solid cubic boron nitride (CBN). The work piece 10 may be produced from a solid body of CBN by means of wire cutting. The work piece has the basic shape of a circular plate having a topside 11, an underside 12 as well as an edge surface 13 extending therebetween. The work piece has a thickness T, which is defined by the distance between the topside 11 and the underside 12. The thickness may be chosen in, for example, the interval of 2-5 mm. The work piece has a centrally placed, through-going hole 14. A number of recesses 15 are arranged at the periphery of the work piece, preferably produced by means of grinding. The number of recesses in the embodiment illustrated is five, but all from two to ten recesses is feasible. The recesses 15 form teeth 16 projecting from a circle C1. The circle C1 is concentric with the center axis CL

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap