Eafd stabilizer for returned concrete and mixer drum wash water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0024]Concrete ingredients were mixed according to the standard ASTM C-192 “Standard Method of Making and Curing Concrete Test Specimens in the Laboratory.” The water-binder ratio of 0.52 and temperatures at 20±2° C. was maintained throughout. Initially, aggregates were added into a mixer together with absorption water. After a few revolutions of the mixer, the cement and the remaining mixing water were added. The mixer was run for about 3 minutes after all the ingredients were added, then left to rest for 3 minutes. Finally, the mixer was run for another 2 minutes.

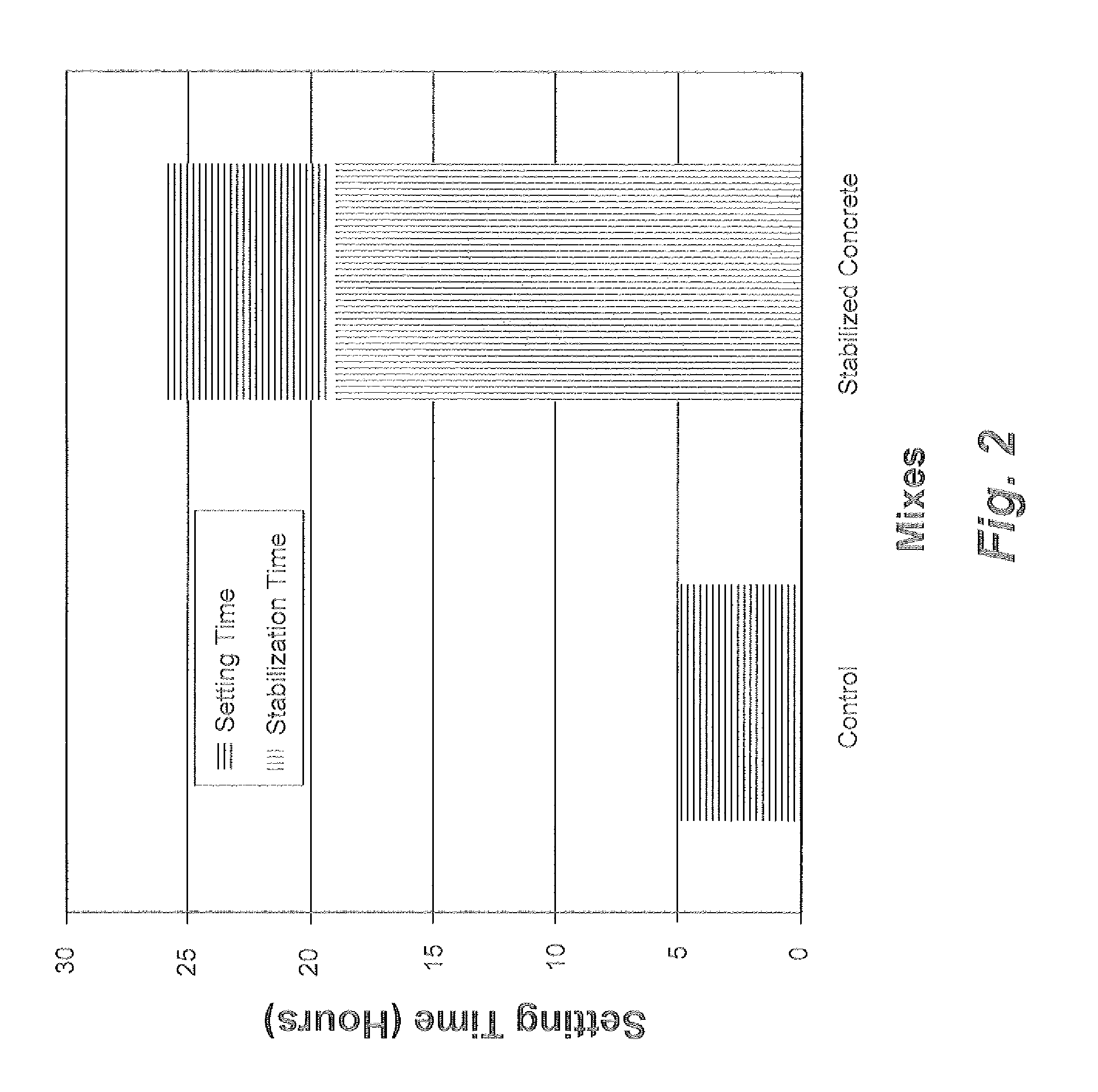

[0025]To simulate the case of using EAFD as a stabilizer for concrete, the specified amount of EAFD was spread out over the concrete mixture, and the amount of water necessary to adjust the water-binder ratio was then added to the mixer. In the non-limiting exemplary embodiment, the amount of EAFD used was about 3% by weight of cement. The mixer was run for other 5 minutes. The fresh concrete was then discharged into wheel b

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap