Film substrate, semiconductor device, method of manufacturing film substrate, method of manufacturing semiconductor device and method of manufacturing circuit board with semiconductor device

a technology of semiconductor devices and film substrates, which is applied in the direction of printed circuit components, printed circuit manufacturing, printed circuit assembling, etc., can solve the problems of difficult handling of film substrate pieces, difficult to achieve the improvement of productivity through automation, and not meeting the needs of miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The embodiment of the present invention will be described below with reference to the accompanying drawings.

[0050] First, the manufacturing method according to the embodiment will be described with reference to FIG. 1A and FIG. 1B to FIG. 13A and FIG. 13B.

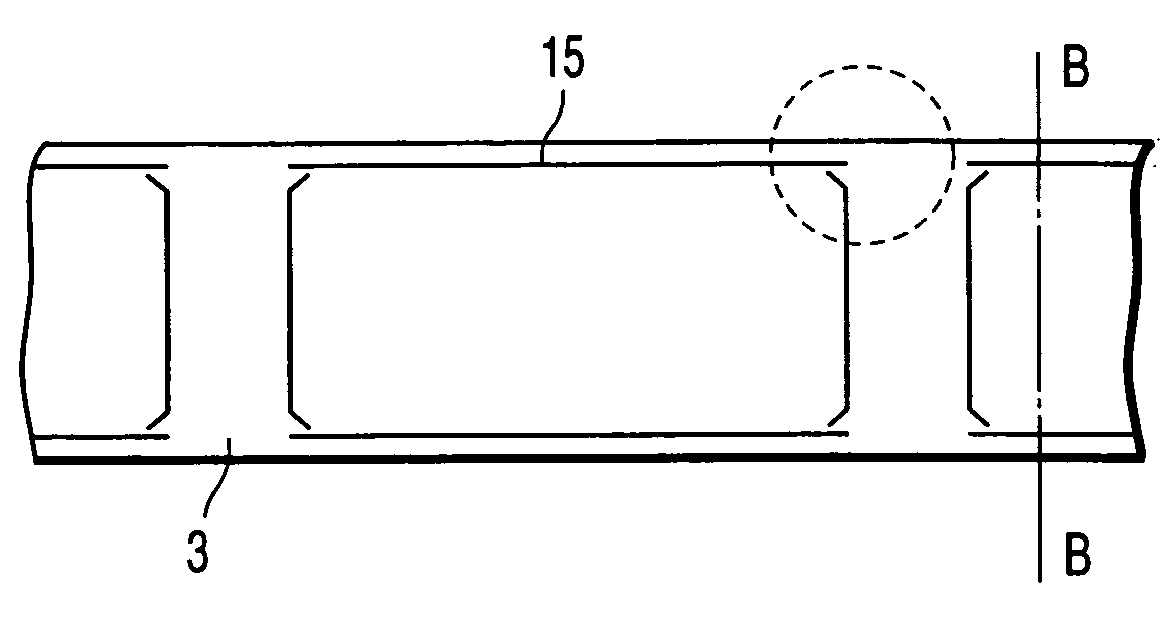

[0051] As illustrated in FIG. 1A and FIG. 1B, a slit is formed in a tape-like insulative film (which corresponds to insulative sheet) 3 such as polyimide and PET (polyester terephthalate) using a metal blade (e.g., Thomson blade) 13 so as to penetrate through the insulative film 3.

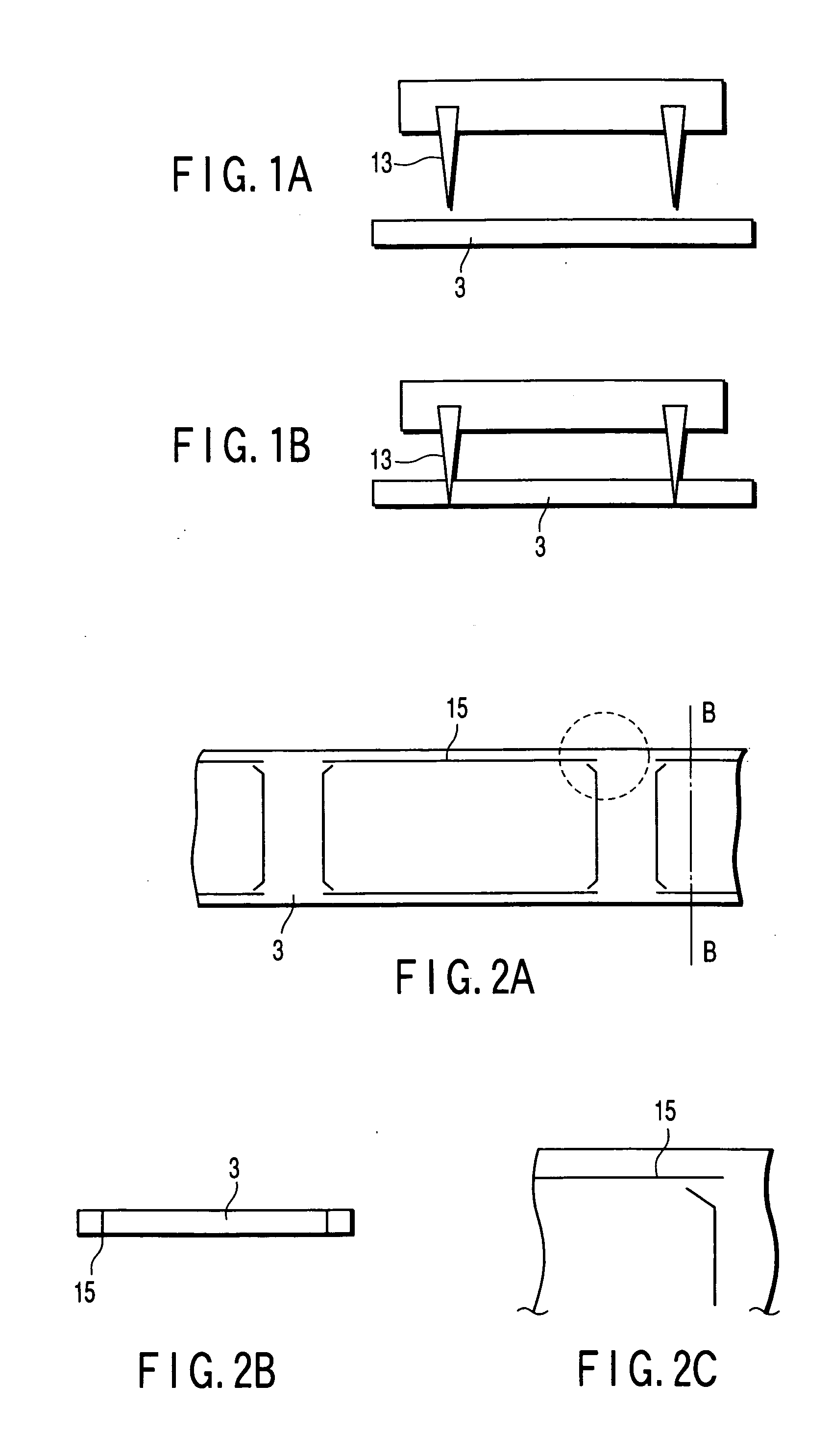

[0052]FIG. 2A is a plan view showing the insulative film 3 with a slit 15, FIG. 2B is a cross-sectional view taken along a line B-B of FIG. 2A, and FIG. 2C is an enlarged view showing a circle shown by the broken line of FIG. 2A. As seen from FIG. 2A, the slit 15 is formed partially along the outer peripheral line (outline) of a separating region (finally necessary region), which will be separated. That is, the slit 15 is not formed over the entire

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap