Clamping device for plug-in unit

A plug-in and gripper technology, which is applied in the field of plug-in clamping devices, can solve problems that affect the efficiency of circuit board space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

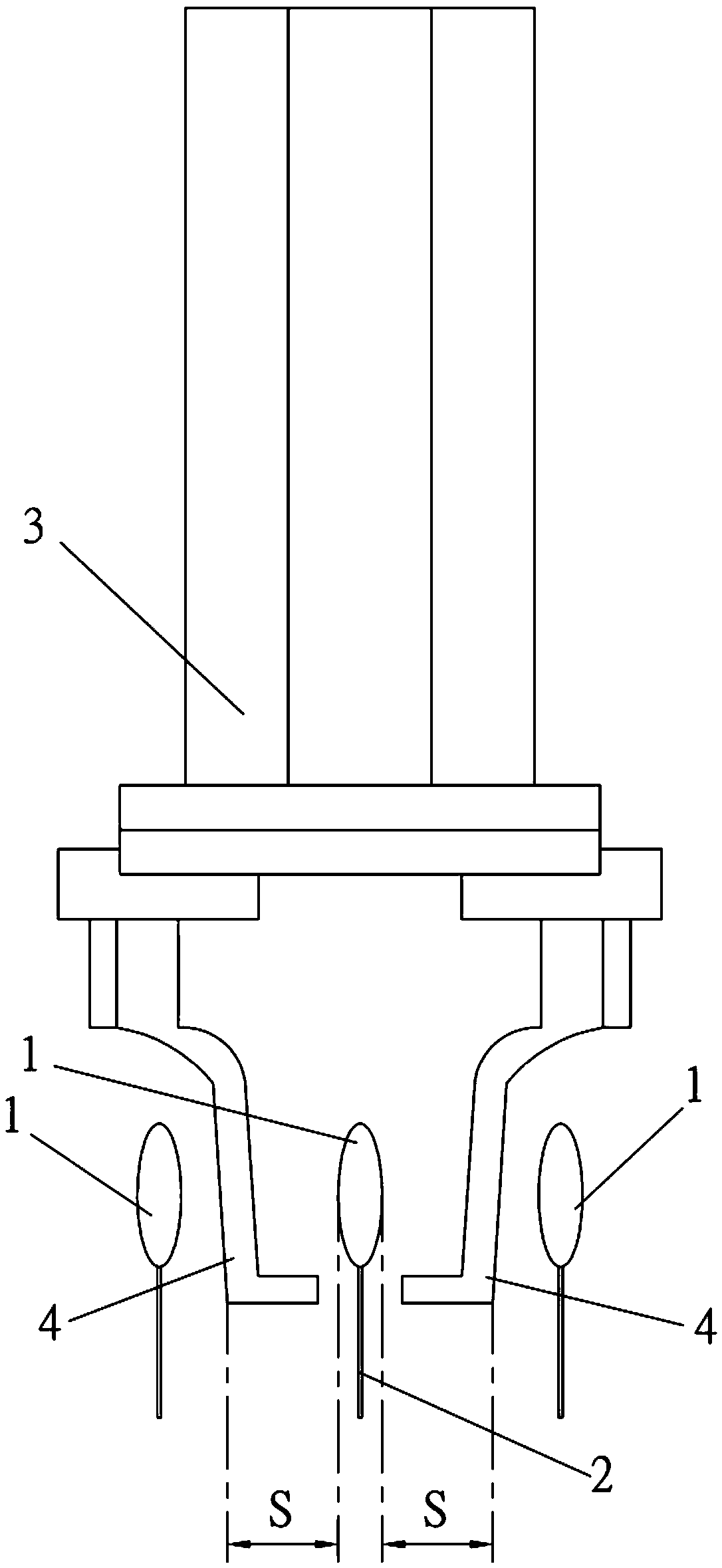

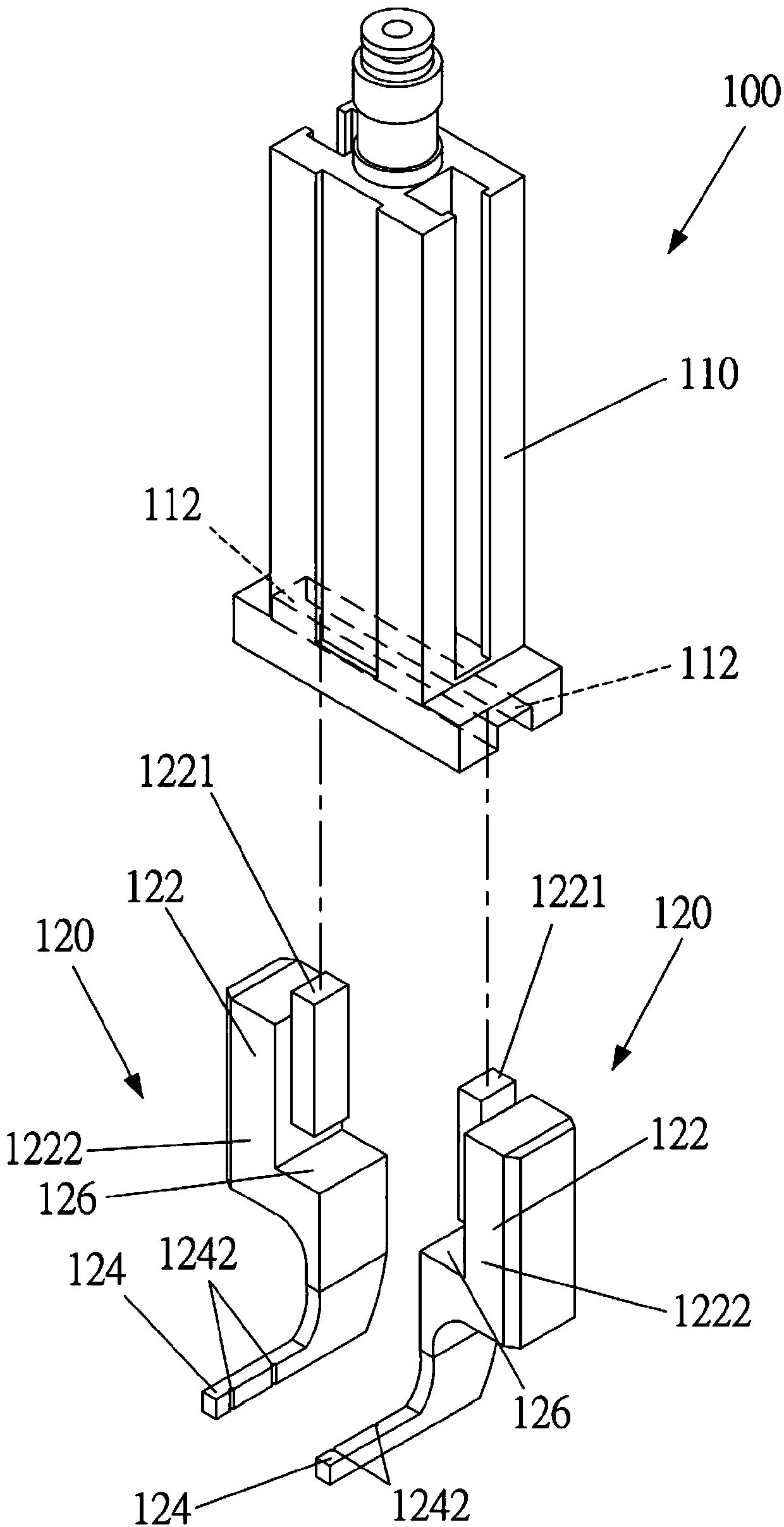

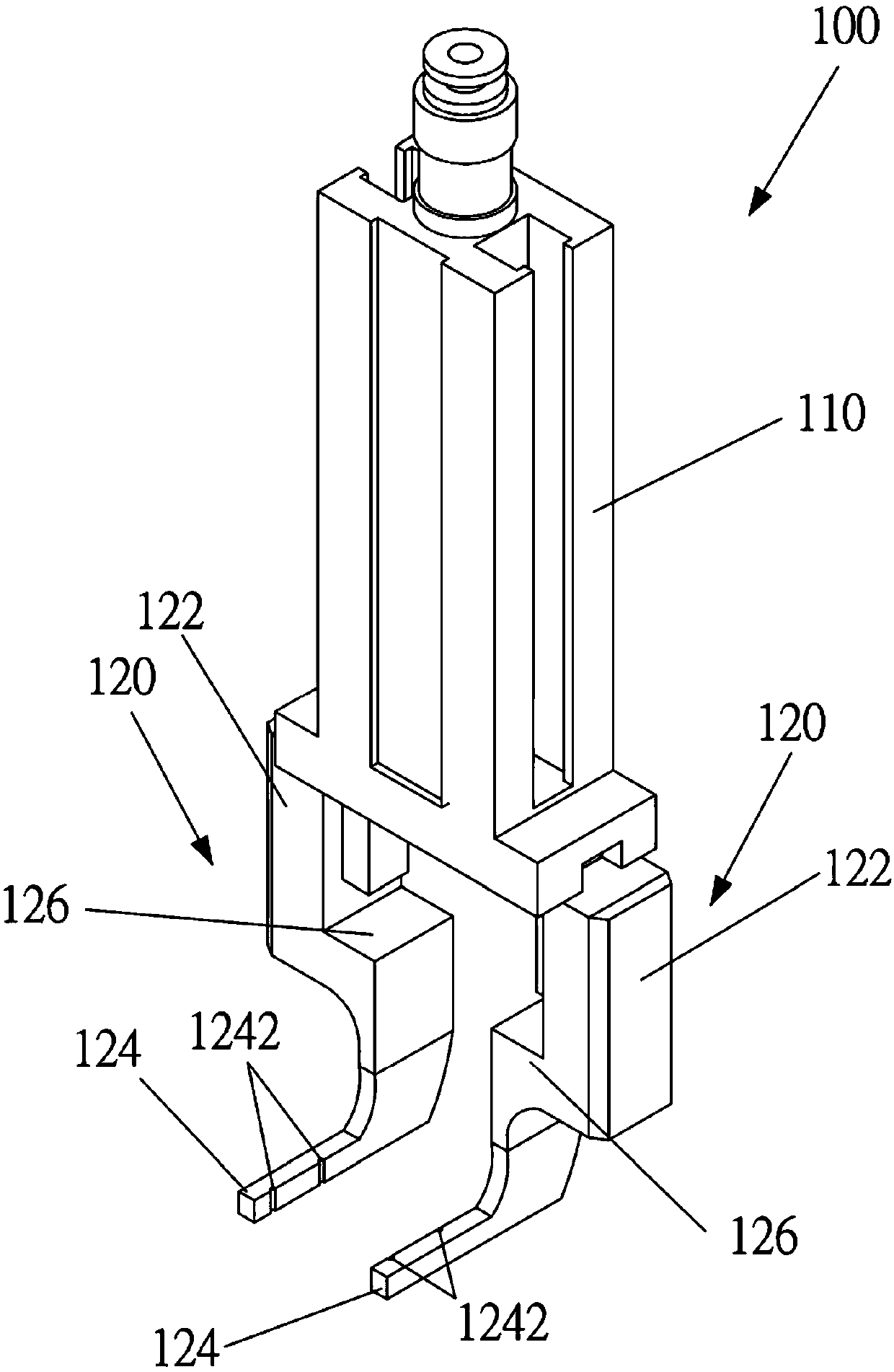

[0049] See attached figure 2 , attached image 3 and attached Figure 4 Shown is a clamping device 100 for inserts according to the first embodiment of the present invention. Insertion refers to the operation of inserting the pin 220 of the electronic component 200 into the conductive through hole 310 (Platating Through Hole) of the circuit board 300 . The aforementioned electronic component 200 includes a body 210 and a plurality of pins 220 ; a specific embodiment of the electronic component 200 is a ceramic capacitor, which has a flat body 210 and two parallel pins 220 . The clamping device 100 is used for clamping the electronic component 200 from the feeding mechanism or the feeding tray, placing the electronic component 200 on a circuit board 300 , and inserting the pin 220 into the conductive through hole 310 of the circuit board 300 . Subsequent soldering is performed to fix the pins 220 to the conductive through holes 310 , so that the electronic components 200 an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap