Supporting and adsorbing jig for PCB

A technology for PCB boards and jigs, applied in the field of PCB board support adsorption jigs, can solve the problems of non-adjustable upper and lower positions of PCB boards, limited scope of application, and affecting the processing accuracy of PCB boards, and achieves wide application range, good versatility, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

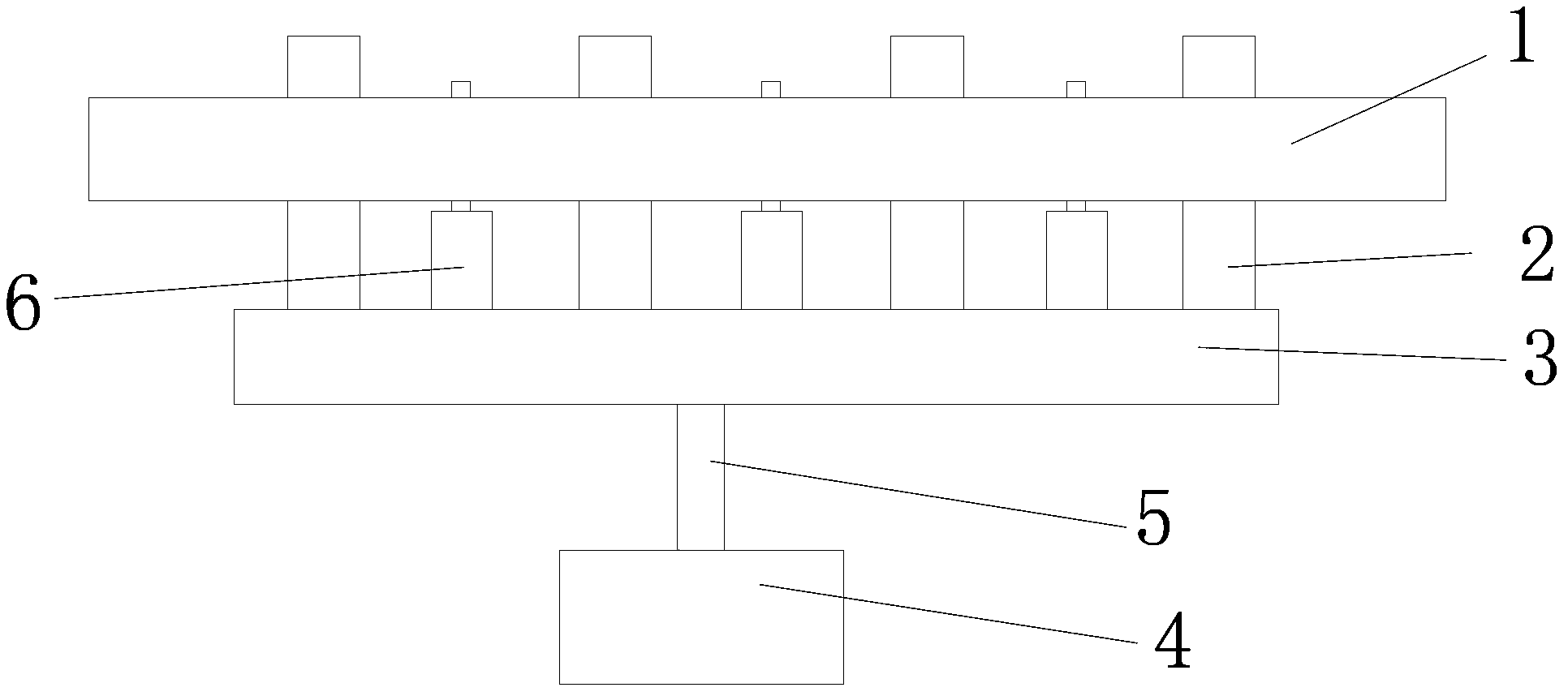

[0014] Such as figure 1 As shown, a PCB board support adsorption jig includes a rectangular base 1, a thimble 2, a moving plate 3, a cylinder 4, an adsorption nozzle 6 and a vacuum generator. The thimble 2 is connected with a moving plate 3 at the bottom of the thimble 2, the bottom of the moving plate 3 is connected with the cylinder rod 5 of the cylinder 4, and three adsorption nozzles 6 are arranged on the moving plate 3, and the corresponding position of the rectangular base 1 is provided with The through hole, the suction nozzle 6 can pass through the through hole, the length of the suction nozzle 6 is less than the length of the thimble 2, and the suction nozzle 6 is connected with the vacuum generator through a pipeline.

[0015] The thickness of the rectangular base 1 is 1 cm, the length of the thimble 2 is 3 cm, and the length of the suction nozzle 6 is 2.5 cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap