Reflow soldering auxiliary tool and reflow soldering method for flexible circuit board

A flexible circuit board and reflow soldering technology, which is applied in the direction of assembling printed circuits with electrical components, can solve problems such as poor soldering, thermal bending deformation and floating of FPC circuit boards, and achieve high operating efficiency and high qualified rate of processed products , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

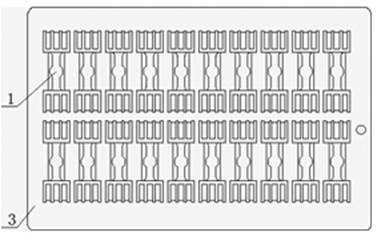

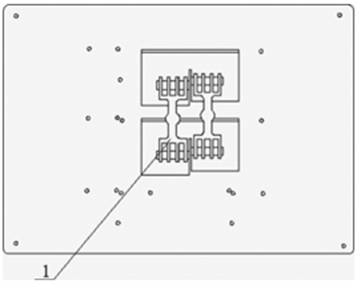

[0014] Such as figure 1 , figure 2 As shown, a reflow soldering auxiliary tool for a flexible circuit board includes a bead 1 and a bead placement tray 3. The bead 1 is a flat and elongated structure with the left half and the right half symmetrical to each other. The middle part of the bead 1 is provided with Circular SMT mounter suction part 2, the bead placement tray 3 is provided with a plurality of bead 1 placement slots corresponding to the shape of the bead 1, and the bead 1 is placed in the bead 1 placement grooves of the bead placement tray 3 .

[0015] A reflow soldering method for a flexible circuit board, comprising the steps of: placing a bead placement tray 3 on which a bead 1 is placed in the tray of an SMT placement machine, and writing data of the bead 1 in the program of the SMT placement machine, such as the suction position , bead 1 size, bead 1

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap