Low-temperature peracetic acid disinfectant and preparation method thereof

A technology of peracetic acid disinfectant and peracetic acid, which is applied in the direction of disinfectants, botany equipment and methods, biocides, etc., can solve the problems of lack of available products, poor disinfection effect, and high irritation of disinfectants, etc. Corrosion of the metal surface and the effect of reducing the stimulation of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030]Preparation of the composite low temperature solvent:

[0031]S1 quantitatively referred to water to add a stirred vessel, quantitatively weigh corrosion inhibitor to add, stir until dissolved;

[0032]S2 quantitatively referred to water soluble thickener, add it to the S1 product, heat dissolved;

[0033]S3 quantitatively weighs organol antifreeze, add quantitative weighted thickening thickener, stir until dissolved;

[0034]S4 was mixed and mixed with S3 products and mixed, filtered, fused.

[0035]The example of the inter-coagulation point detection method of the embodiment is, a temperature measurement method.

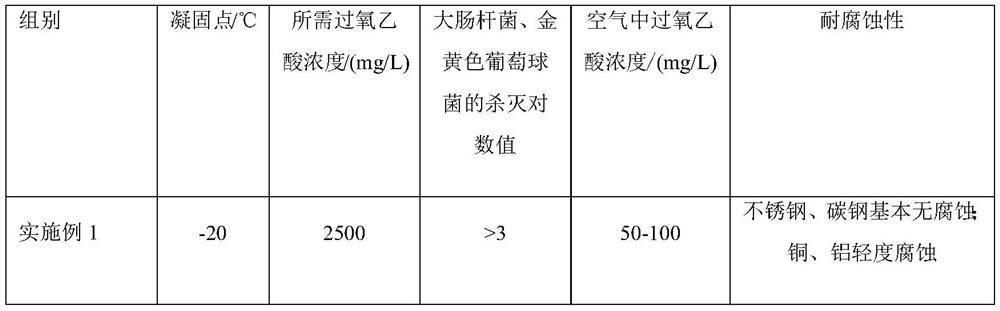

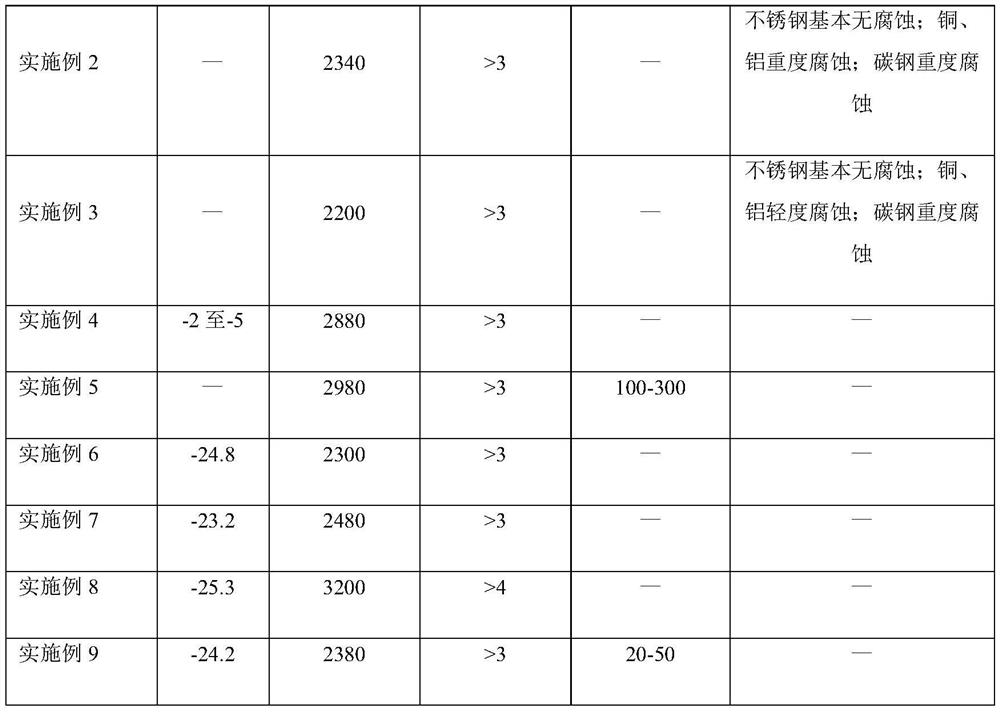

[0036]The embodiment of the example system is detected, and the field simulation test, statistical E. coli, golden staphylococcal value>3 At the concentration of peroxyacetate required.

[0037]The example system volatility detection method is: the solution is applied in a disinfectant amount of 1 g / 24 cm * 33 cm, which is uniformly sprayed on a sizes of 24 cm * 33 cm plastic self-sea

Embodiment 1

[0046]Based on the disclosed embodiment, a low-temperature peroxoacetic acid disinfectant embodiment is preferable, and its components include:

[0047]Peroxidic acid: 15% -18% peroxoic acid concentrated solution, mass 3.3 g.

[0048]Composite low temperature solvent: mass 96.7g; each component is composed, 45g, antifreeze ethanol 8g, antifreeze ethylene glycol 18g, antifreeze isopropanol 4g, thickener polyvinylpyrone 0.01-3 g, EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc EtOAc.

[0049]The samples required in Example 1 were prepared in the preparation method of low-temperature peroxoacetic acid disinfectant preparation method.

Embodiment 2

[0051]Based on the disclosed embodiment, a low-temperature peroxyacetic acid disinfectant embodiment is disclosed as a first control group. The corrosion inhibitor components in its components are phytic acid less than 5%, and the pentaerythritol is less than 10%, and benzatoxazole is less than 5%, and the siloxane is less than 10%, and the remaining same is the same as in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap