Method for drying ceramic green body in drying chamber

A ceramic green body and drying method technology, applied in the field of ceramic production, can solve the problems of high cracking rate and long time consumption of the green body, and achieve the effects of reducing the process, increasing the cracking rate, and increasing the drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] A preferred embodiment is given below to illustrate the present invention more clearly and completely in conjunction with the accompanying drawings.

[0027] A method for drying a ceramic body in a drying oven, which includes the following steps:

[0028] Step 1. Place the ceramic body in the drying room.

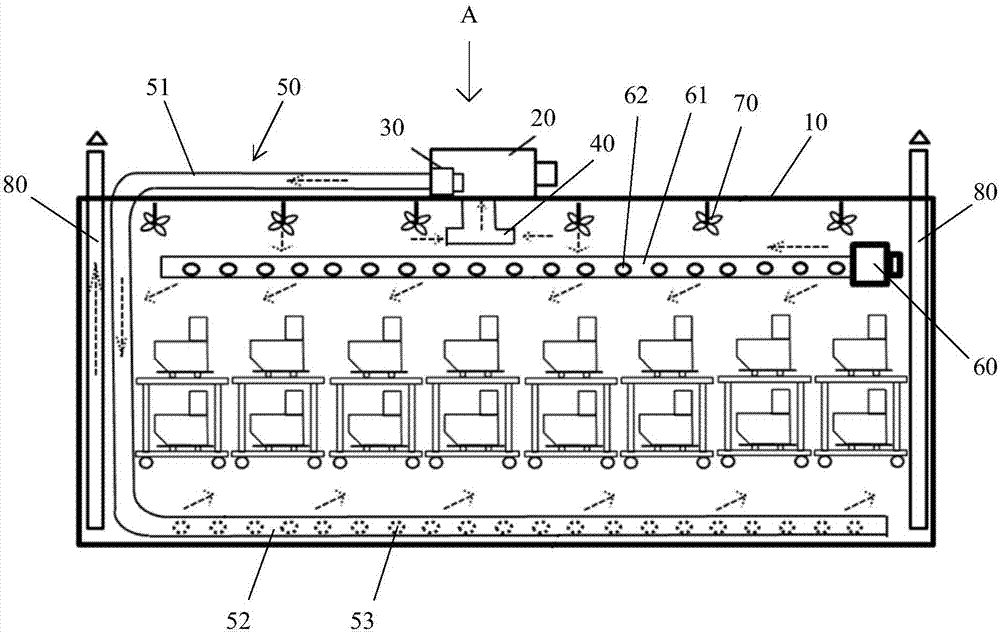

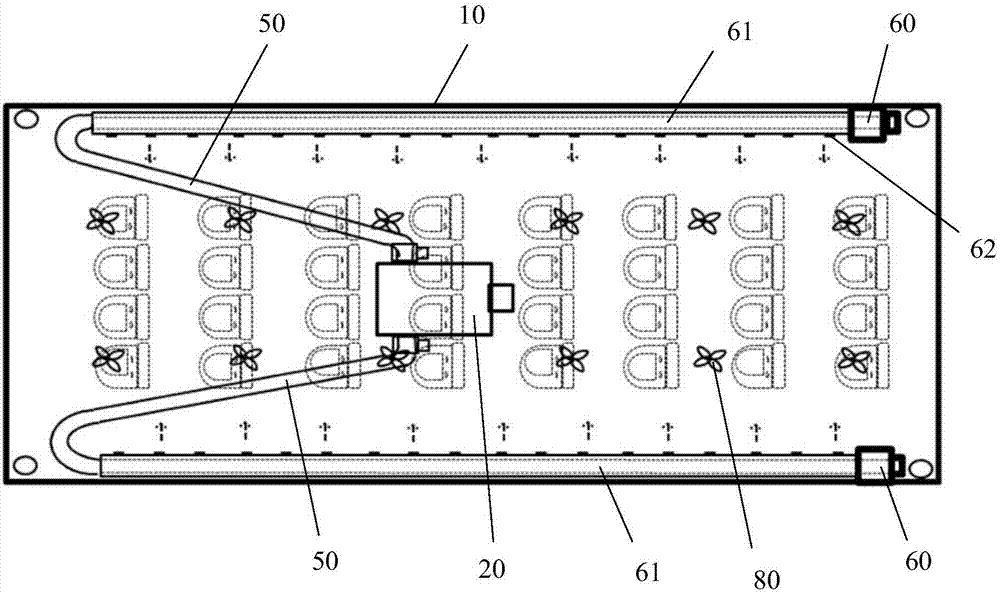

[0029] Such as figure 1 with figure 2 As shown, the drying room includes a room body 10, and a hot air generating system 20 is provided on the outside of the room body 10. The hot air generation system 20 includes a circulating fan 30 and an air inlet 40, and the air inlet 40 is located at the top of the inner cavity of the house 10.

[0030] The circulating fan 30 is connected with two circulating air ducts 50. Each circulating air pipe 50 includes an air supply pipe section 51 connected to the circulating fan 30 and an air outlet pipe section 52 connected to the air supply pipe section 51. The air outlet pipe section 52 is provided with a plurality of circulating air outlet

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap