Dried sea cucumber manufacturing method capable of keeping high purity of holothurian saponins

A sea cucumber saponin, high-purity technology is applied in the direction of drying and preserving meat/fish, etc., which can solve the problems of complicated and complicated drying methods, high cost of drying sea cucumbers, long processing time, etc., so as to avoid deformation of sea cucumbers and avoid nutrients. The effect of draining and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

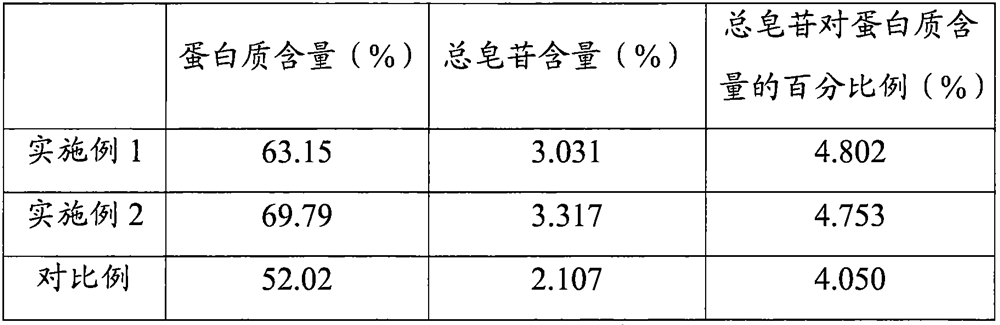

Examples

Embodiment 1

[0028] A sea cucumber light-dried method for retaining sea cucumber saponins with high purity comprises the following steps:

[0029] (1) Cleaning: Make an incision on the abdomen of the sea cucumber, rinse it with salt water pressurized to 90Pa to remove the internal organs, then wash the mucus attached to the inner and outer surfaces with light salt water, and then soak it in water for 5 hours;

[0030] (2) Low-temperature aging: place the sea cucumbers cleaned in the step (1) in a steam pot at 60°C for 3 hours at low temperature until the skin is tight and the thorns are hard, and then cool naturally to obtain ripened sea cucumbers;

[0031] (3) Preliminary drying: the sea cucumber cooked in step (3) is air-dried at low temperature, and the temperature gradient is controlled to carry out multi-stage air-drying, specifically:

[0032] (3.1) Preliminary dehumidification: put the matured sea cucumbers evenly in the drying tray and send them into the drying tunnel, set the tempera

Embodiment 2

[0039] A sea cucumber light-dried method for retaining sea cucumber saponins with high purity comprises the following steps:

[0040] (1) Cleaning: Make an incision on the abdomen of the sea cucumber, rinse it with salt water pressurized to 110Pa to remove the internal organs, then wash the mucus attached to the inner and outer surfaces with light salt water, and then soak it in water for 3 hours;

[0041] (2) Low-temperature aging: place the sea cucumbers cleaned in the step (1) in a steam pot at 65°C for 2 hours at low temperature until the skin is tight and the thorns are hard, and then cool naturally to obtain ripened sea cucumbers;

[0042] (3) Preliminary drying: the sea cucumber cooked in step (3) is air-dried at low temperature, and the temperature gradient is controlled to carry out multi-stage air-drying, specifically:

[0043] (3.1) Preliminary dehumidification: put the matured sea cucumbers evenly in the drying tray and send them into the drying tunnel, set the temper

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap