Cutter head molding machine

A technology of molding machine and cutter head, applied in the direction of manufacturing tools, grinding racks, grinding machine parts, etc., can solve problems such as low production efficiency, and achieve the effect of improving processing efficiency, improving molding accuracy and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Attached to the following Figure 1-4 This application will be described in further detail.

[0035] The embodiment of the present application discloses a cutter head molding machine.

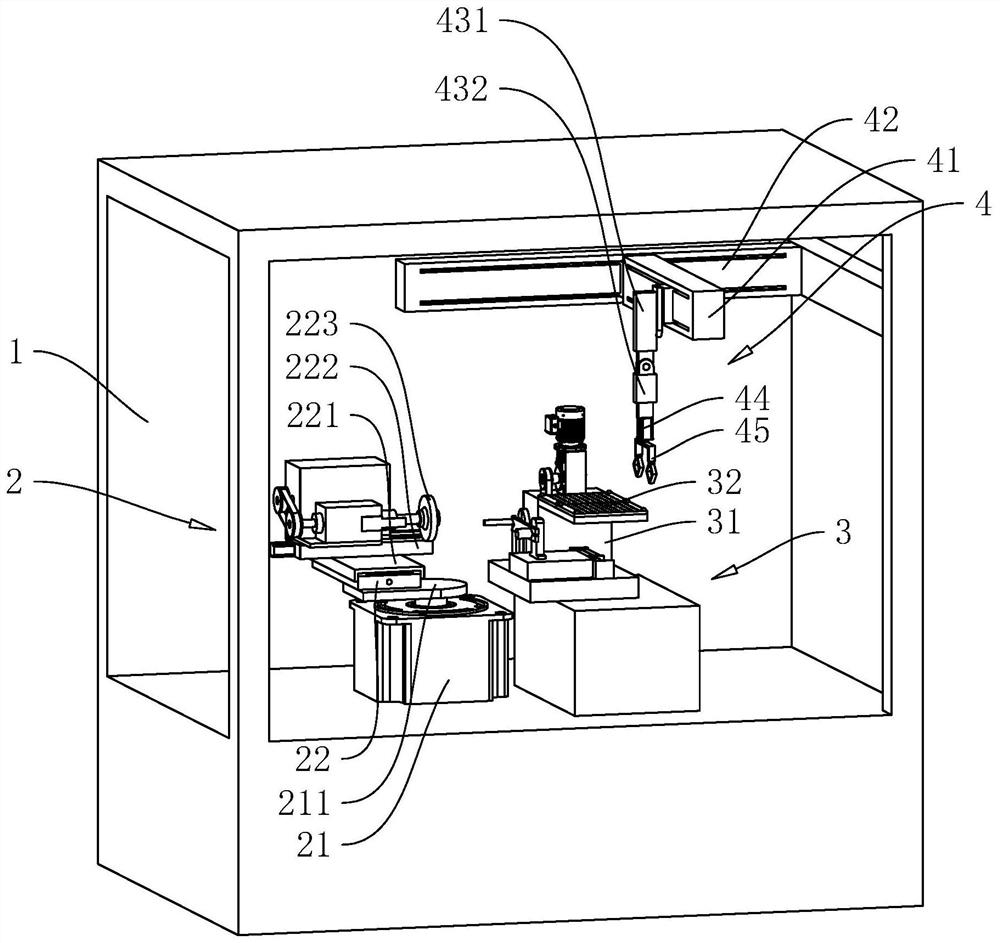

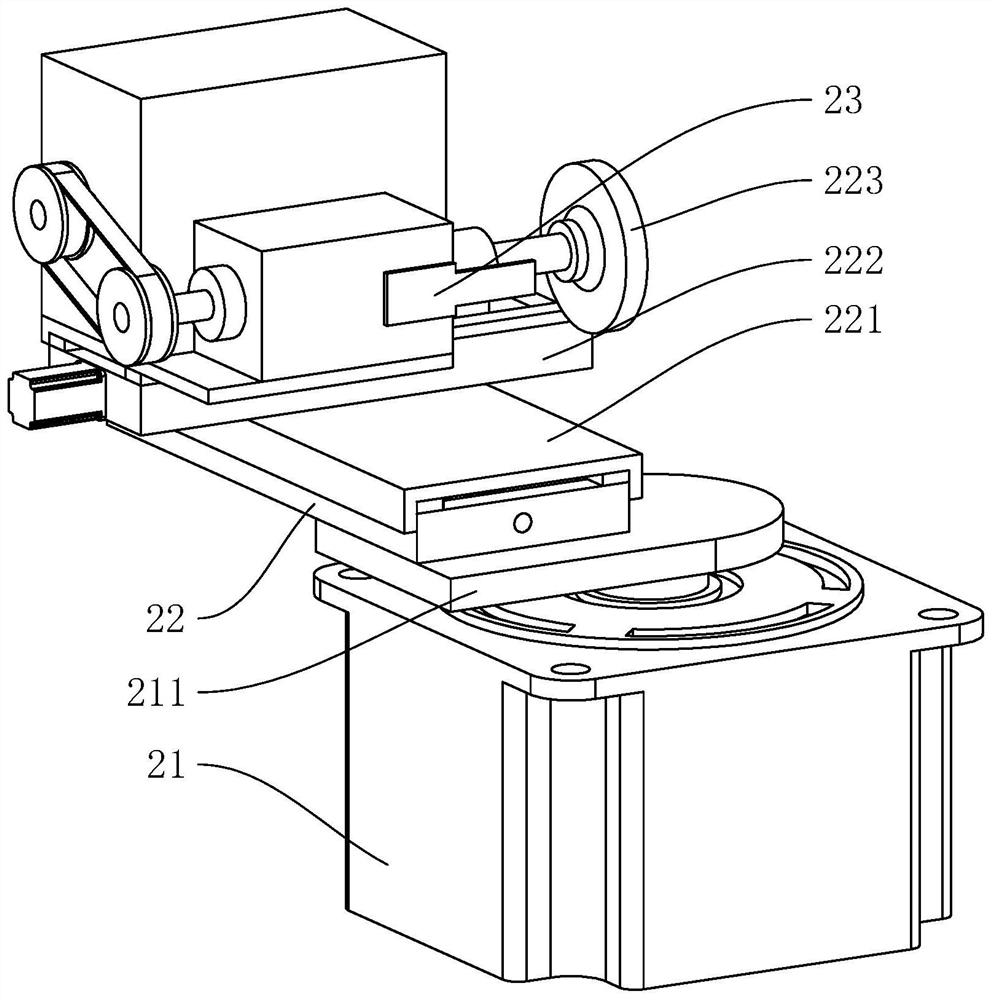

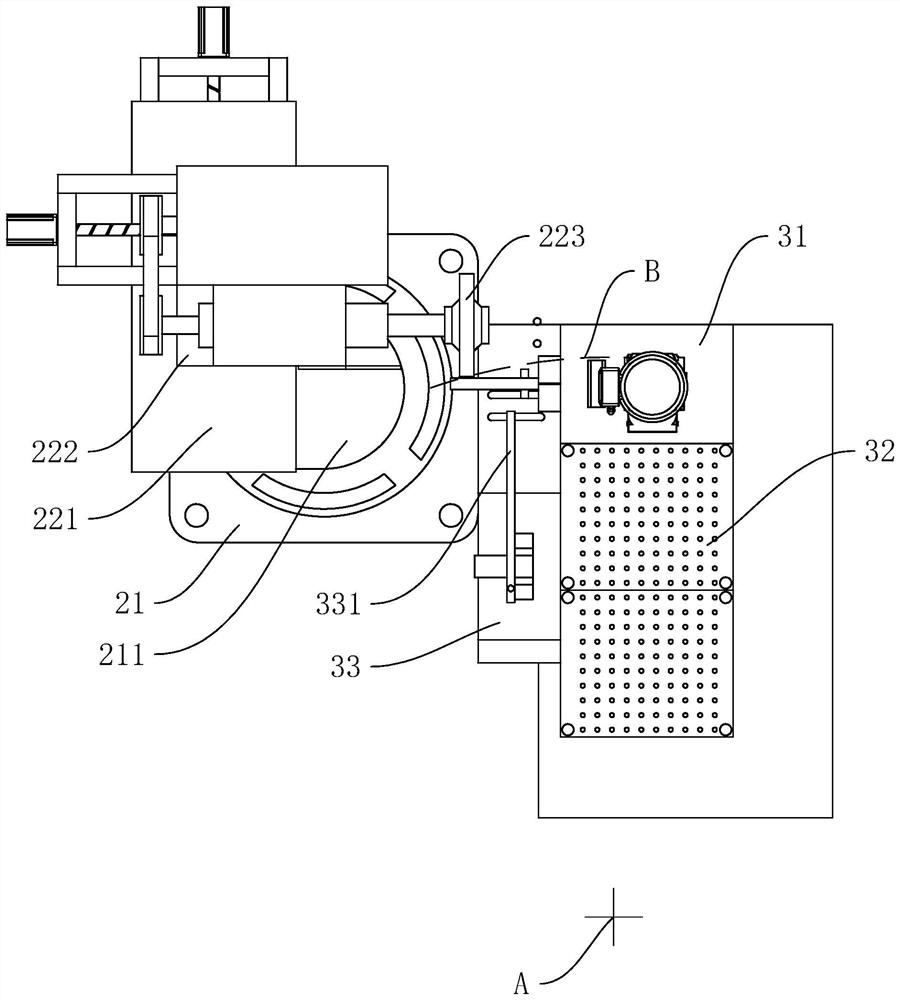

[0036] refer to figure 1 and figure 2 , a cutter head molding machine includes a frame 1, the frame 1 is provided with a modeling assembly 2, a fixing assembly 3 and a feeding assembly 4, and the modeling assembly 2 includes a rotating motor 21 fixed on the base of the frame 1, which rotates A turntable 211 is fixedly connected to the output shaft of the motor 21 , a fixing block 22 is fixedly arranged on the turntable 211 , a first sliding block 221 is arranged on the fixing block 22 through the sliding of a screw rod, and the first sliding block 221 is provided with a screw rod. The sliding is provided with a second sliding block 222, the sliding direction of the first sliding block 221 and the sliding direction of the second sliding block 222 are perpendicular to each other; the seco

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap