Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Product processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Product by process is an online compilation of processes , material and interesting stories about products. Product by process is an attempt to go beyond the polished products and objects that surround us and take a look at how they are manufactured and recycled.

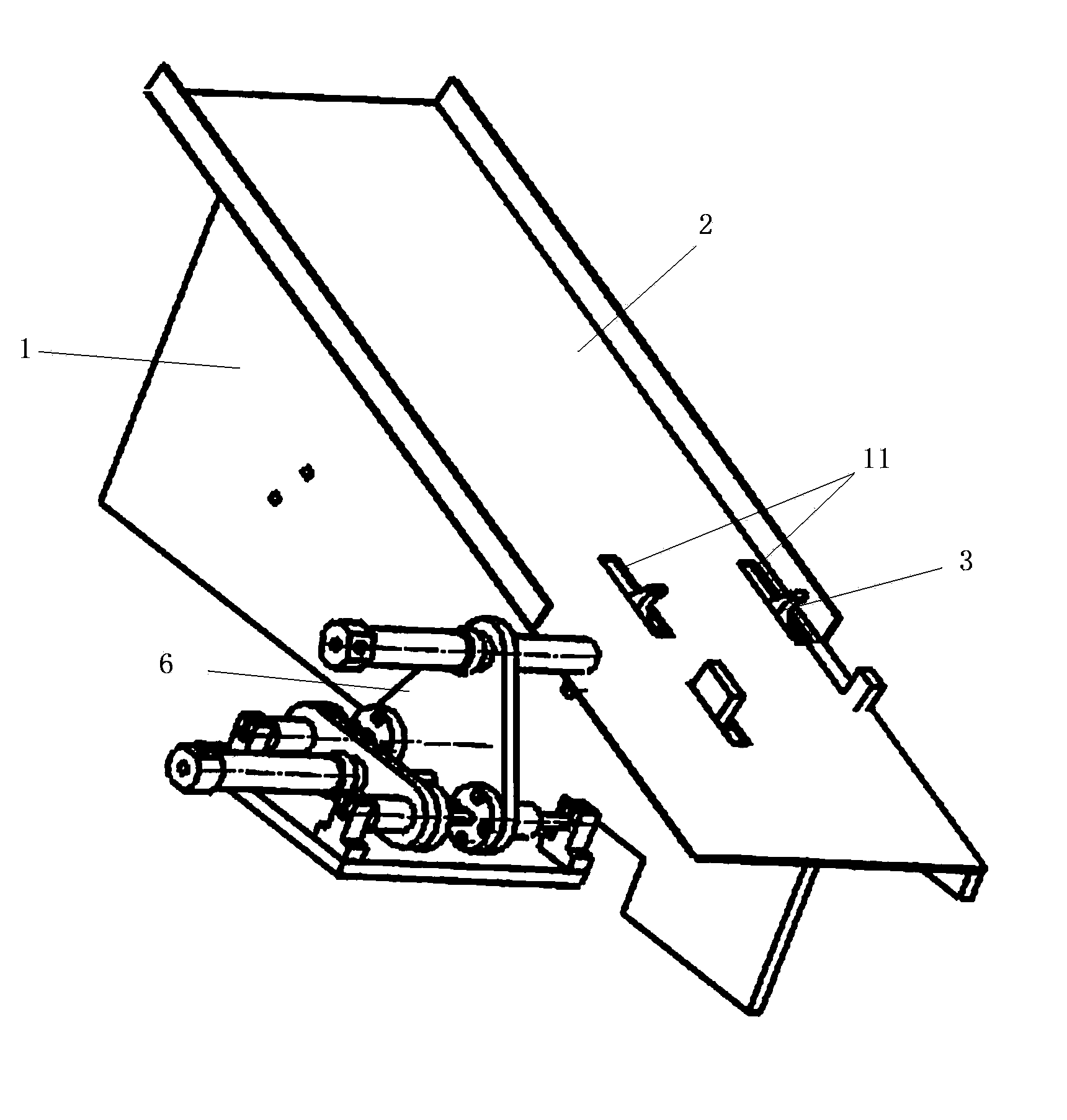

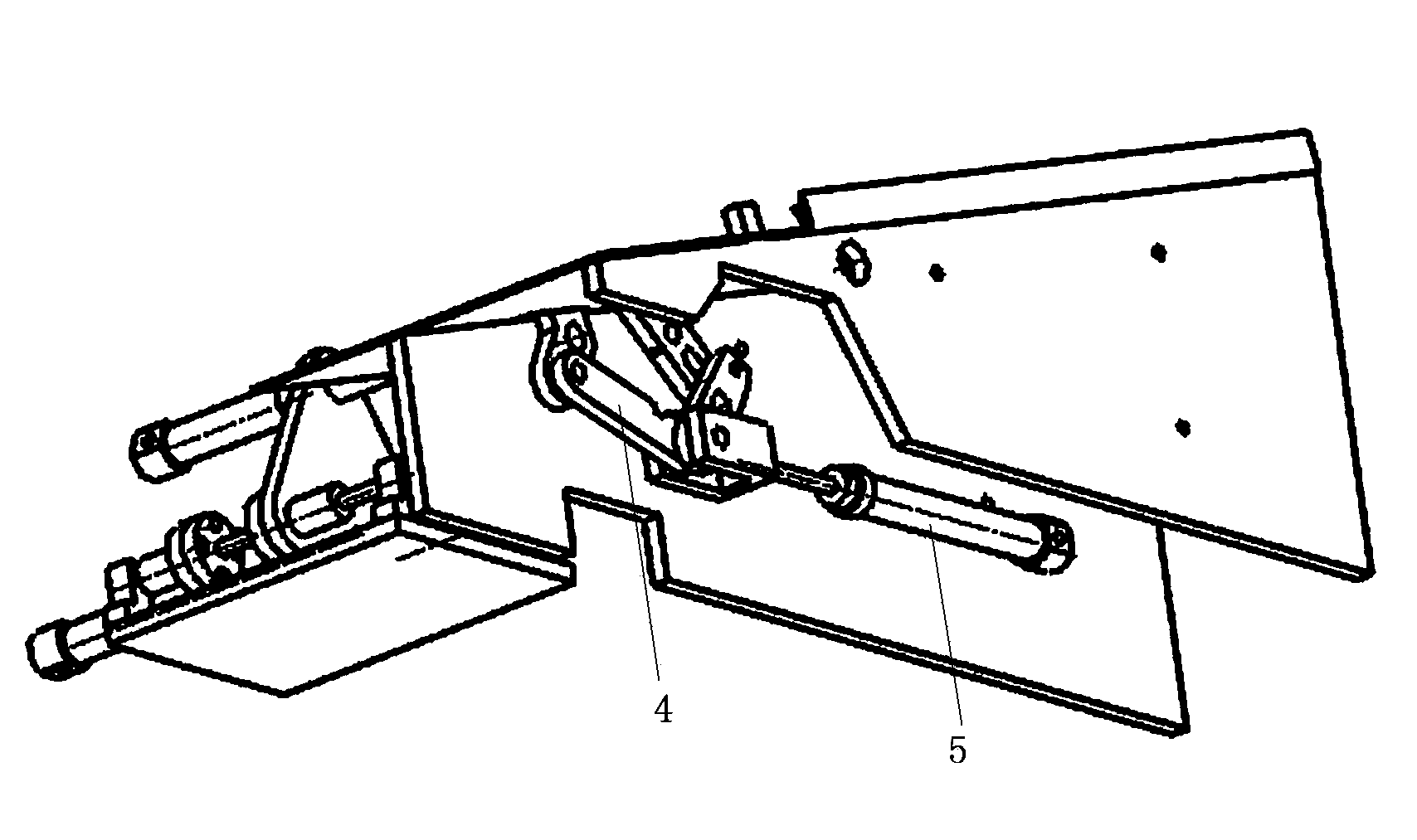

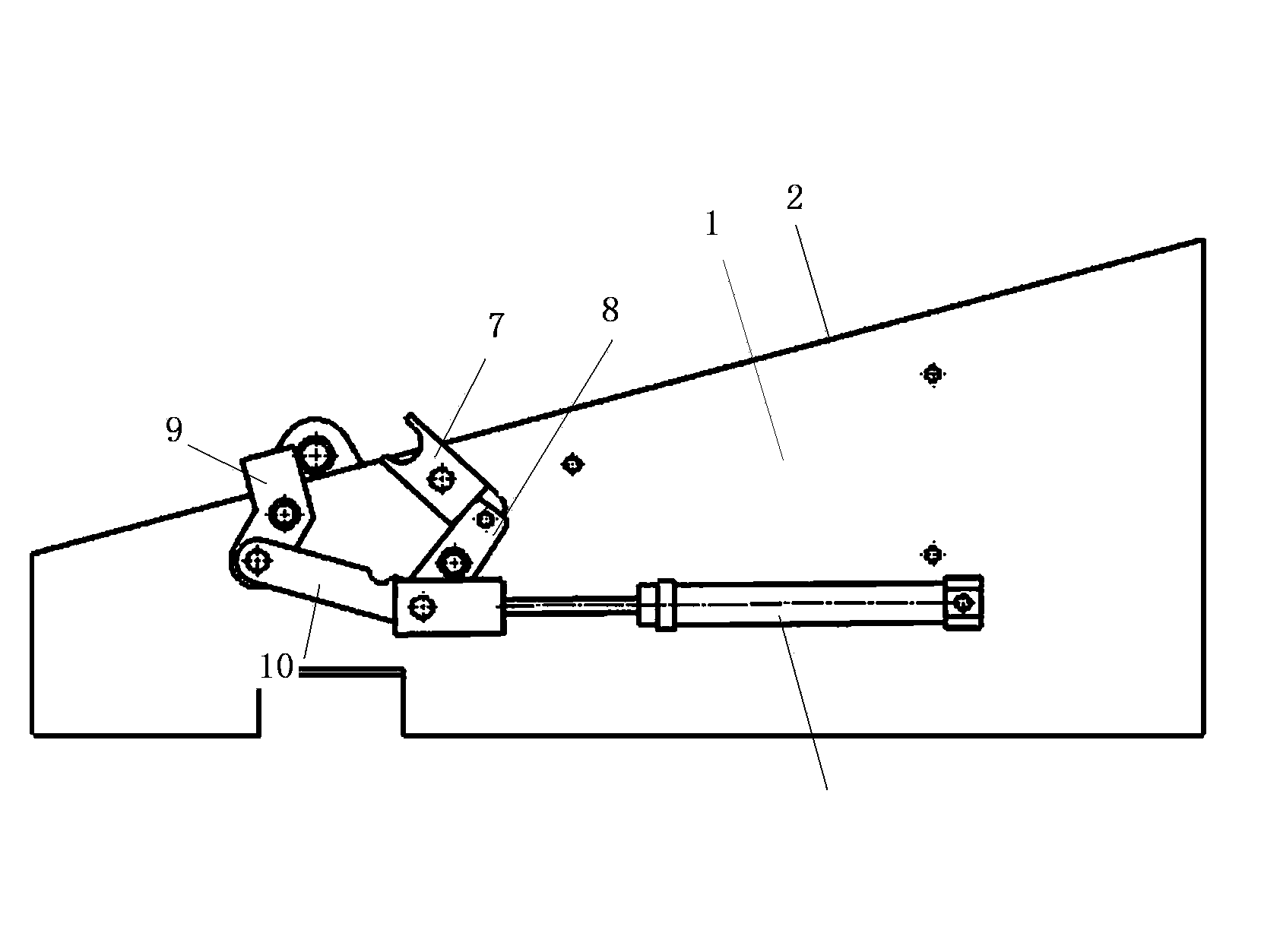

Manually-positioning intermittent edge ironing equipment for shoes

Owner:温州市万润鞋业有限公司

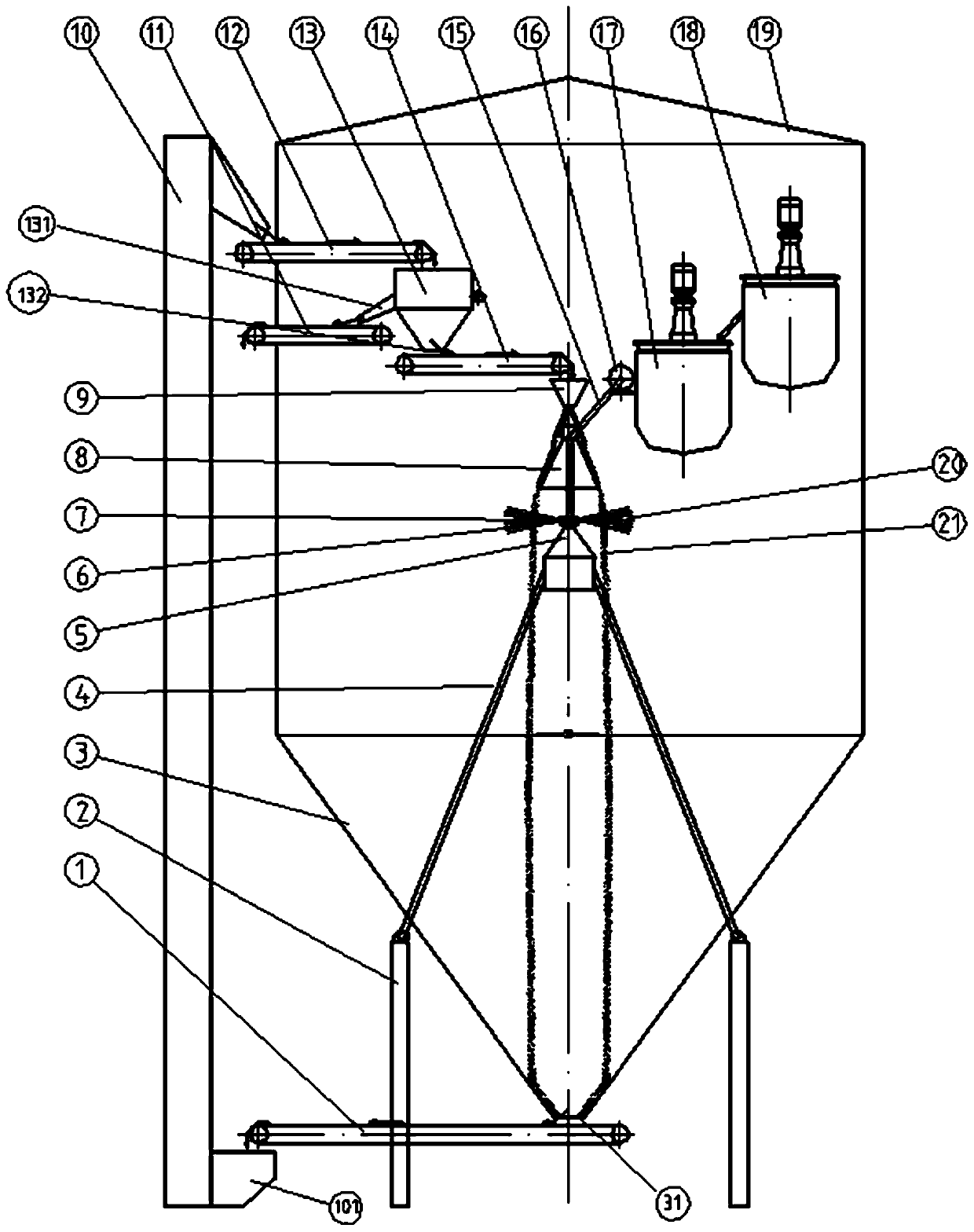

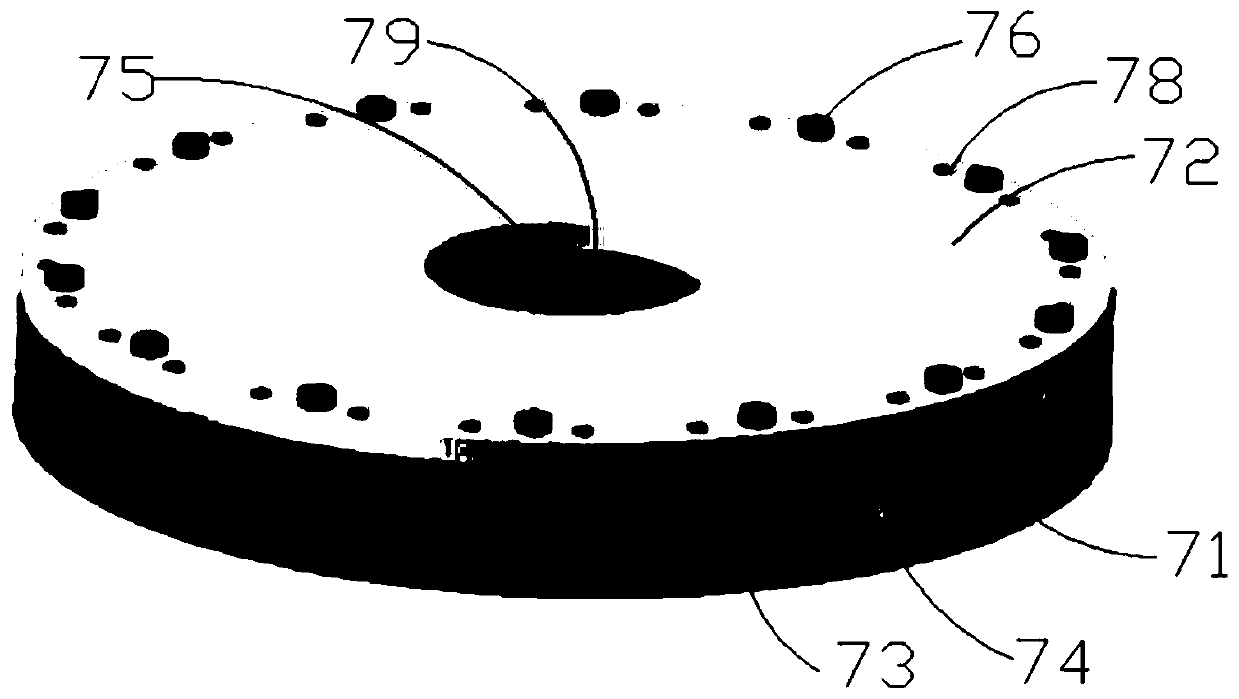

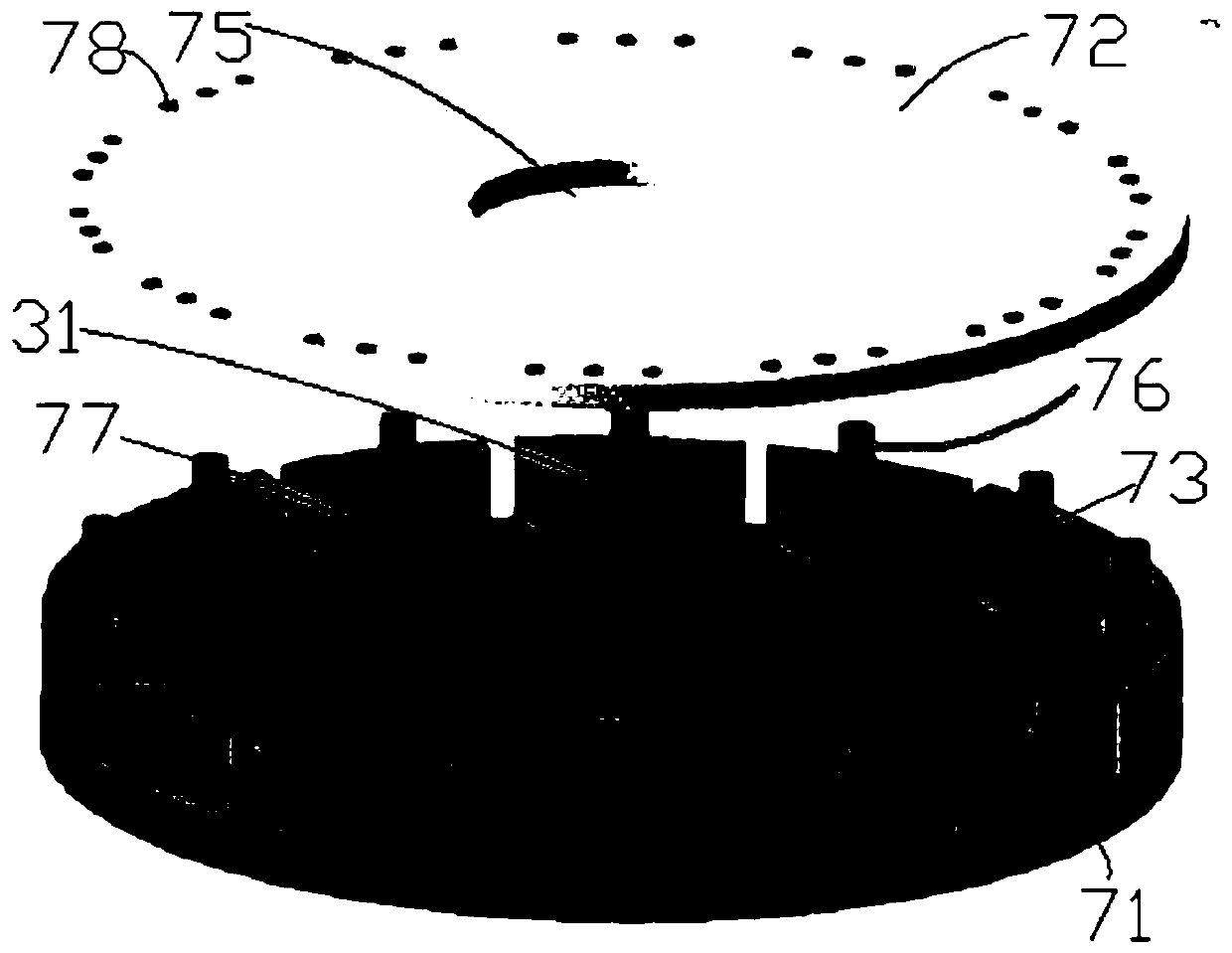

Annular coating granule chemical fertilizer pelletizing tower and process pelletizing method thereof

PendingCN110449090ASmall sizeAvoid easy cloggingGranulation by liquid drop formationGranulation by powder suspensionTowerProduct processing

Owner:SHENZHEN BATIAN ECOTYPIC ENG

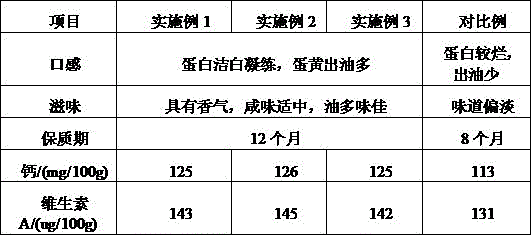

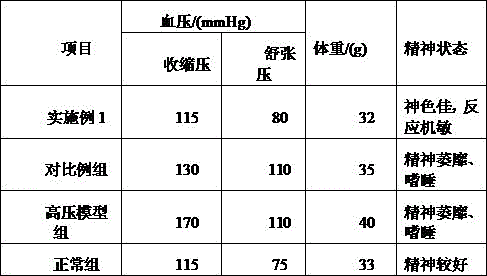

Spiced salted duck egg

InactiveCN106722366AAdd flavorHeightened sensory shapeFood ingredient functionsPhyllanthus urinariaAmorpha fruticosa

Owner:界首市昌盛养殖专业合作社

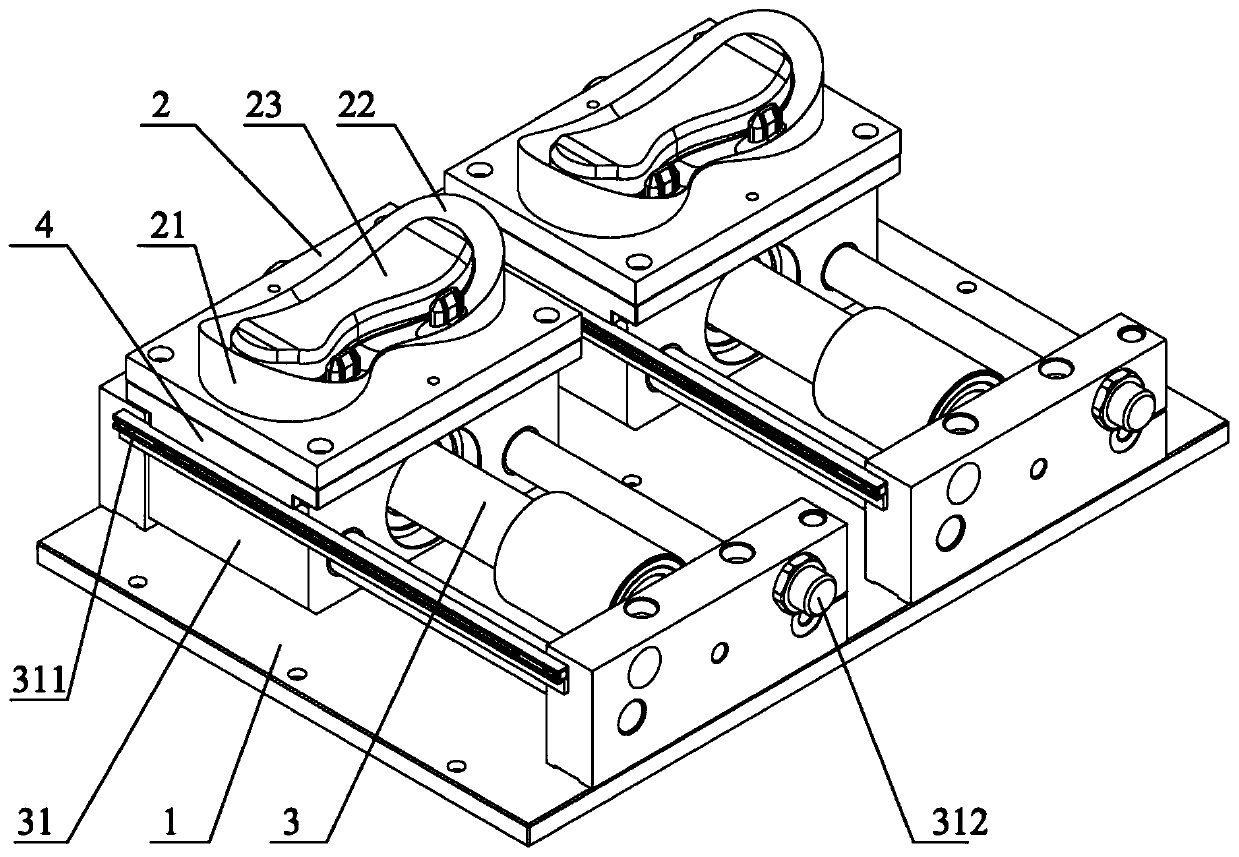

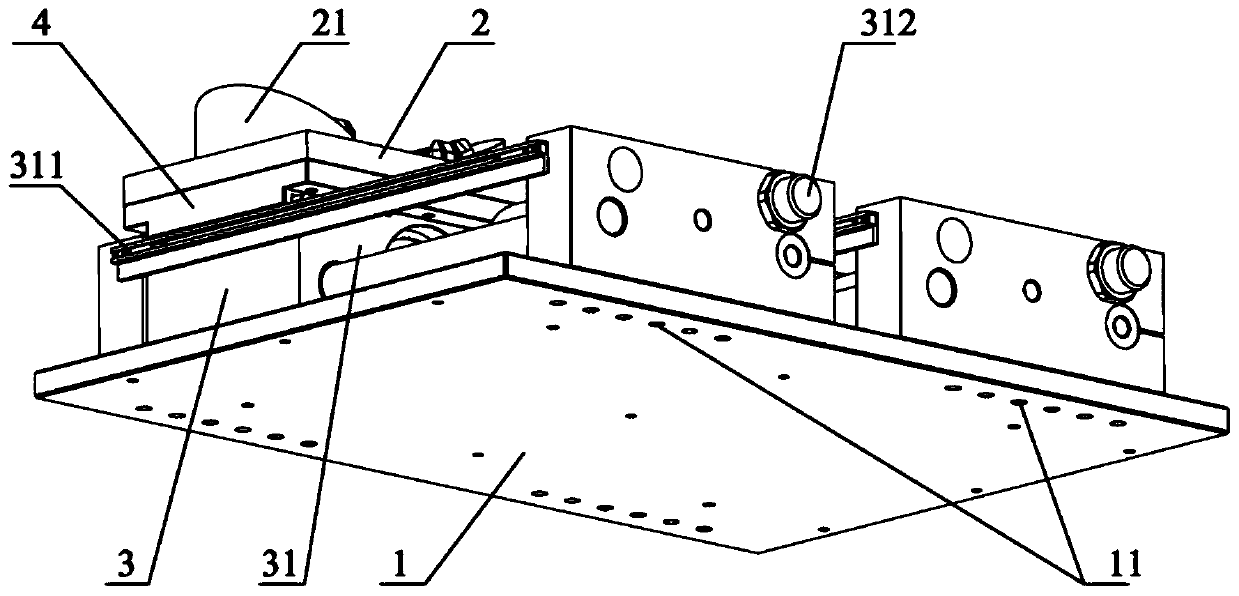

Continuous food 3D printer

The invention relates to the technical field of agricultural product processing equipment, and provides a continuous food 3D printer, which comprises a rotating platform, a clamping extrusion mechanism, an X-axis motion mechanism, a Y-axis motion mechanism, a Z-axis motion mechanism and a plurality of raw material extrusion heads; the plurality of raw material extrusion heads are detachably connected to the rotating platform; the Z-axis motion mechanism drives the Y-axis motion mechanism to move in the Z-axis direction, the Y-axis motion mechanism drives the X-axis motion mechanism to move inthe Y-axis direction, and the X-axis motion mechanism drives the clamping extrusion mechanism to move in the X-axis direction; the clamping extrusion mechanism is used for clamping the raw material extrusion heads and extruding the raw material from the raw material extrusion heads. The continuous food 3D printer is provided with the plurality of raw material extrusion heads, so that raw materialswith various tastes can be added to the printed food.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

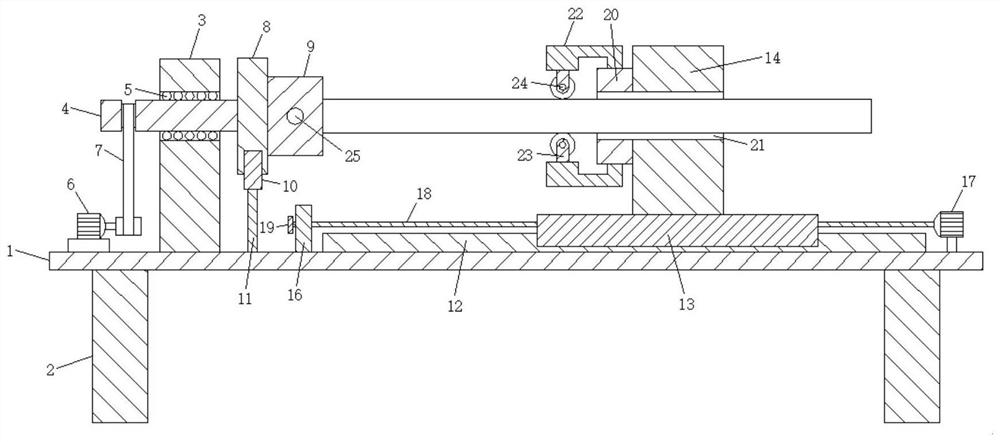

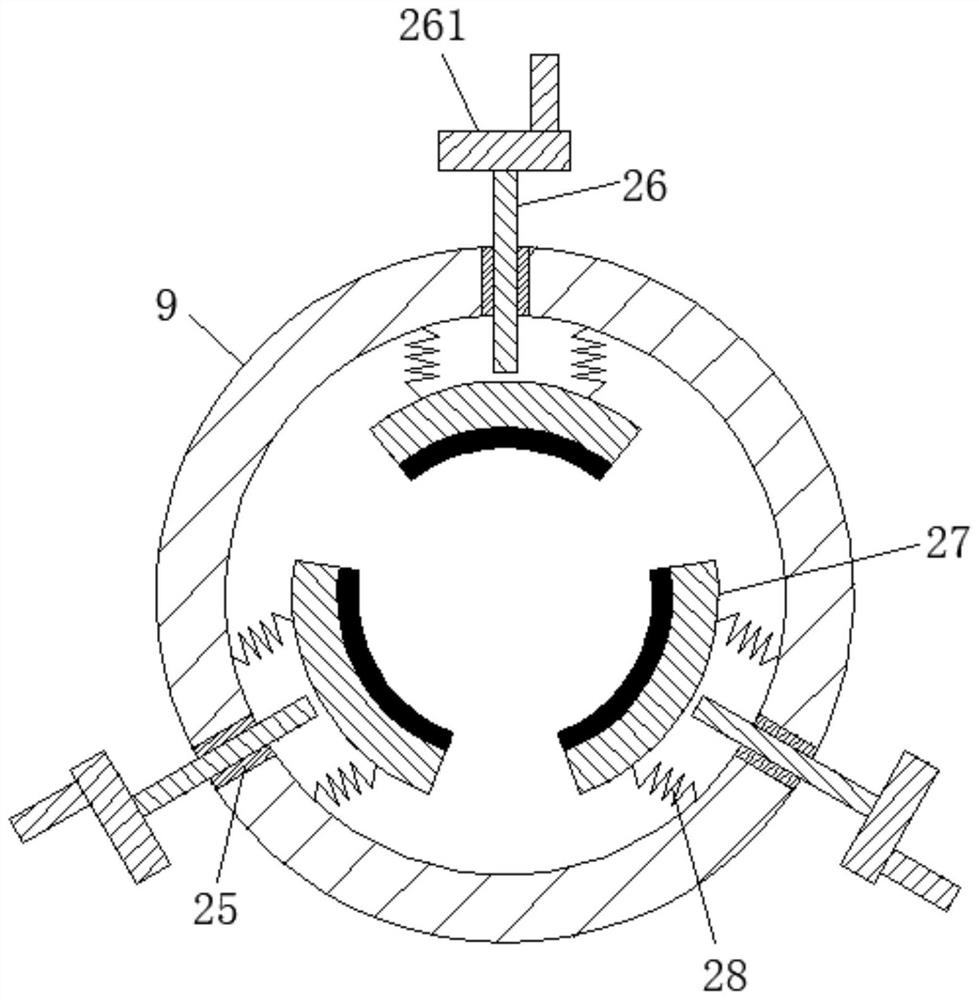

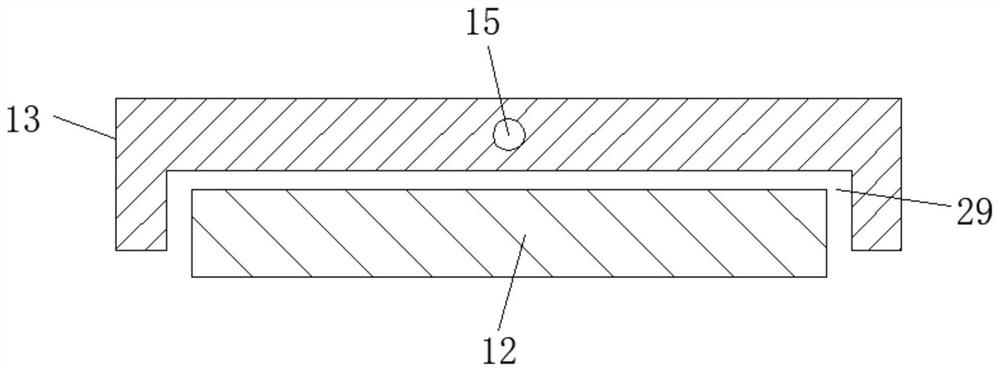

Automatic pipe feeding mechanism

ActiveCN103567314AImprove product qualityFast processingMetal-working feeding devicesPositioning devicesIndustrial AccidentEngineering

Owner:上海汽车空调配件股份有限公司

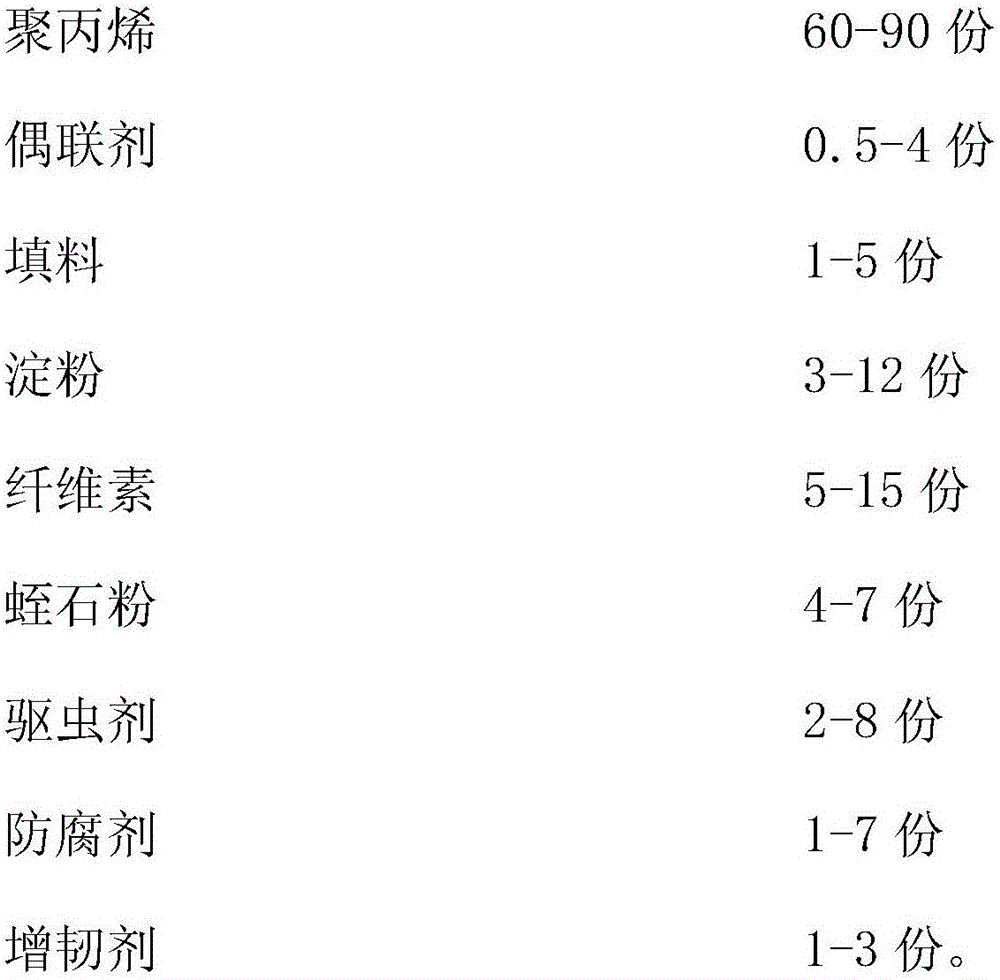

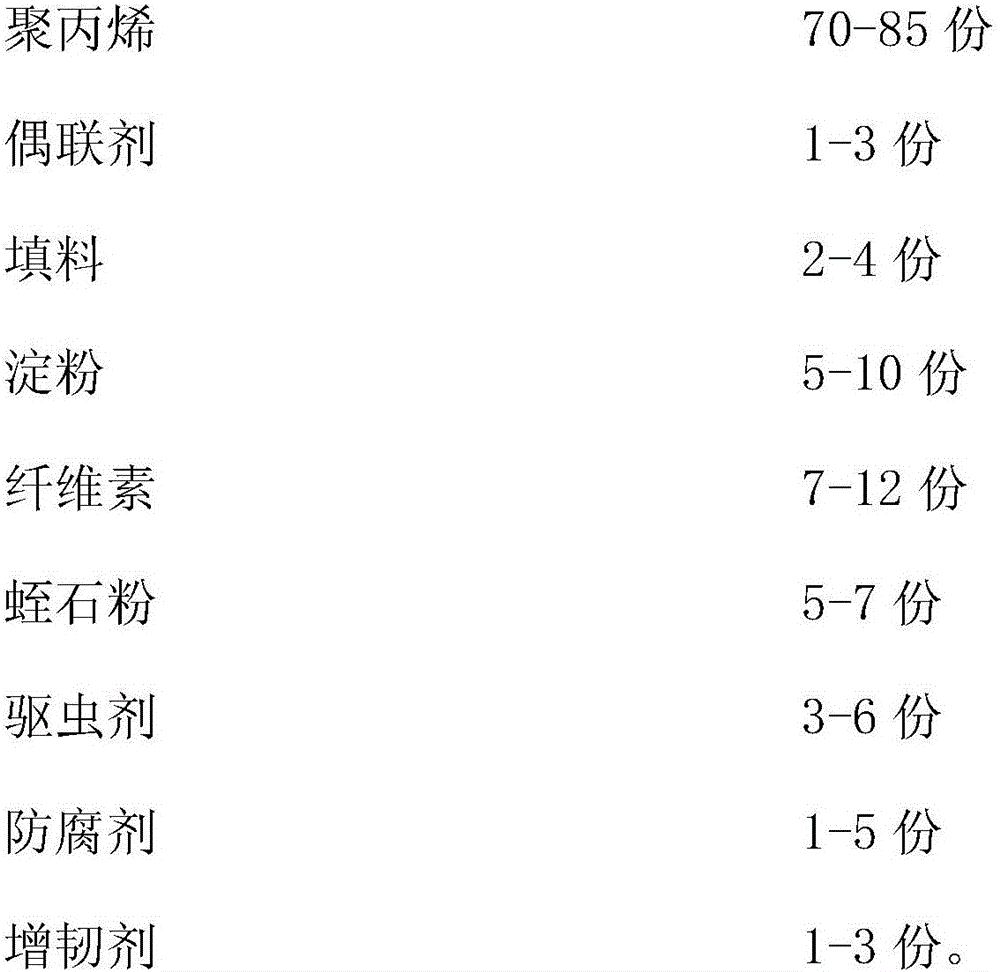

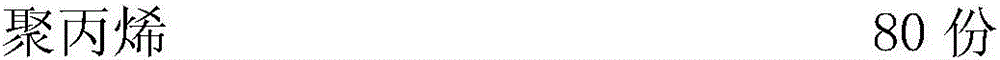

Food packaging bag and preparation method thereof

Owner:安徽明诚塑业有限公司

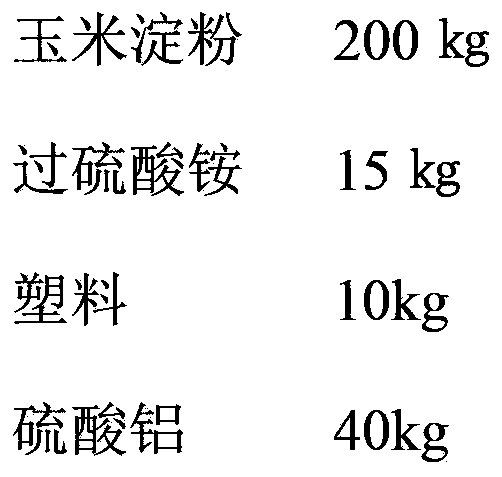

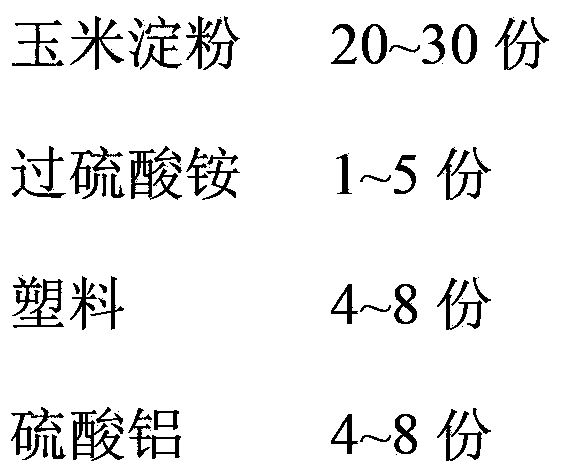

Method for preparing corrugated paper

InactiveCN103410039AHigh indexStrength Enhancement BoostWater-repelling agents additionPaper/cardboardPulp and paper industryHigh intensity

Owner:安徽浙源再生纸业科技有限公司

Twisting machine device for tubular product processing

Owner:TIANJIN SHENGFA IND & TRADE

Jiaxian Zizyphus jujuba Mill. fermentation primary pulp wine brewing method

InactiveCN106867836APlay a role in improving quality and efficiencyFull of nutritionAlcoholic beverage preparationDistillationFood flavor

Owner:杜军锋

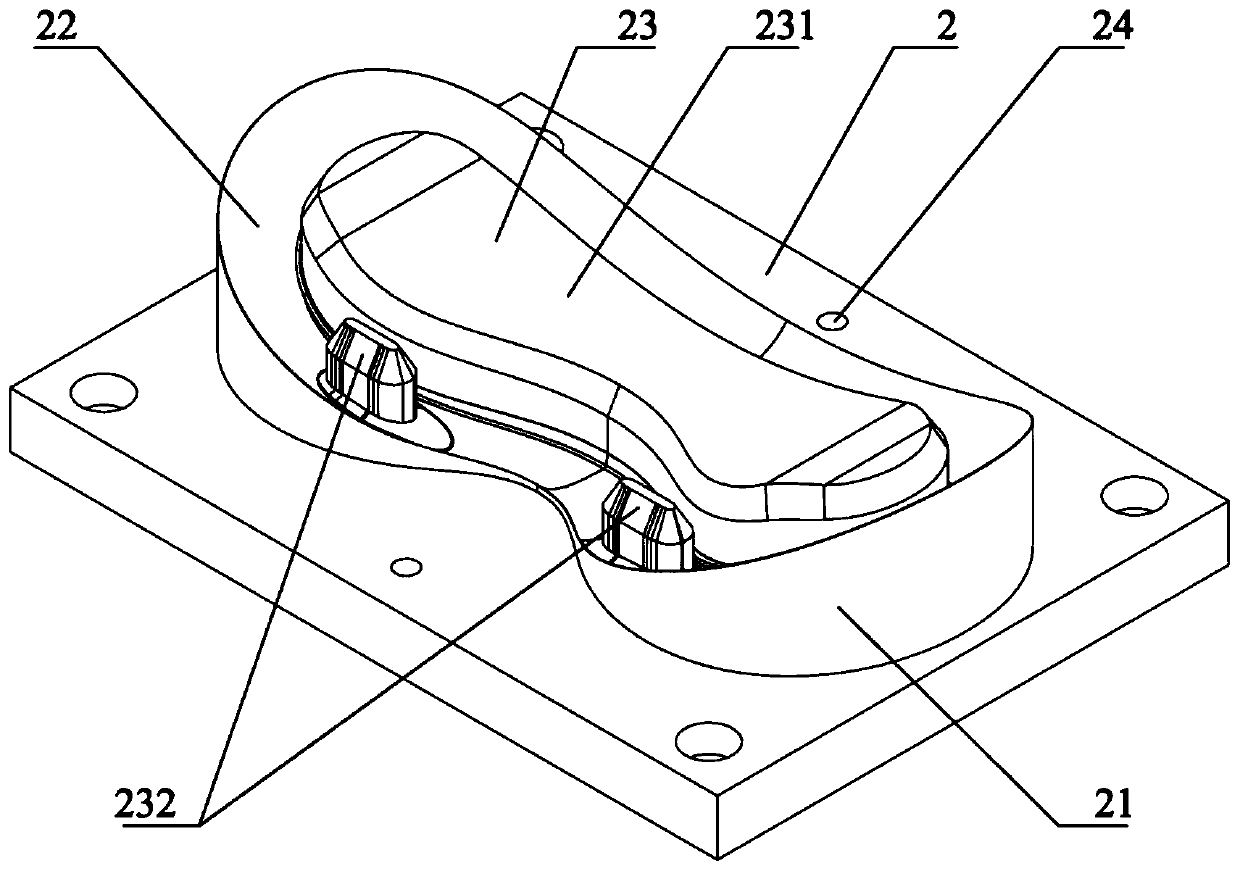

Efficient grinding method for waterproof sealing strip

ActiveCN111993242AImprove grinding efficiencyIncrease contact areaGrinding drivesGrinding machinesElectric machineEngineering

The invention provides an efficient grinding method for a waterproof sealing strip, and belongs to the technical field of rubber product processing. A corresponding positioning screw is selected according to the size of the waterproof sealing strip. The depth of a first guide groove in the positioning screw is required to be less than the thickness of the waterproof sealing strip. Outward pullingis conducted from the end portion of the waterproof seal strip wound around a discharge wheel. Winding is conducted on a discharge screw along a second guide groove by a plurality of rings, then penetrating into a first guide groove is conducted from one end of the positioning screw, then traction onto a winding wheel is conducted from the other end of the first guide groove, a grinding wheel abuts against the waterproof sealing strip on the middle section of the first guide groove, a driving motor, a winding motor and an air pumping motor are started, the discharge screw and the grinding wheel rotate synchronously, the positioning screw is static, the waterproof sealing strip slides in the first guide groove relative to the positioning screw at a uniform speed, and all portions of all waterproof sealing strips wound on the discharge wheel are caused to be sequentially subjected to rough grinding, fine grinding and polishing. The efficient grinding method has the advantages of being capable of continuously performing high-efficiency grinding on the single side of the waterproof sealing strips and the like.

Owner:HUBEI UNIV OF SCI & TECH

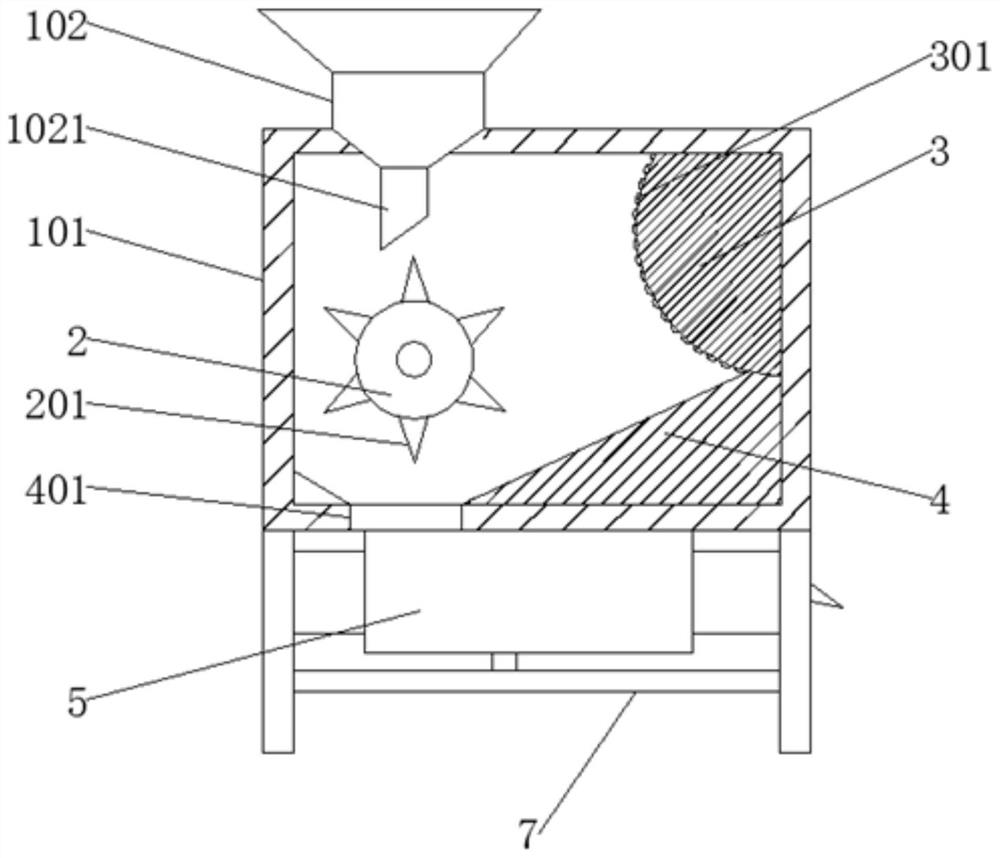

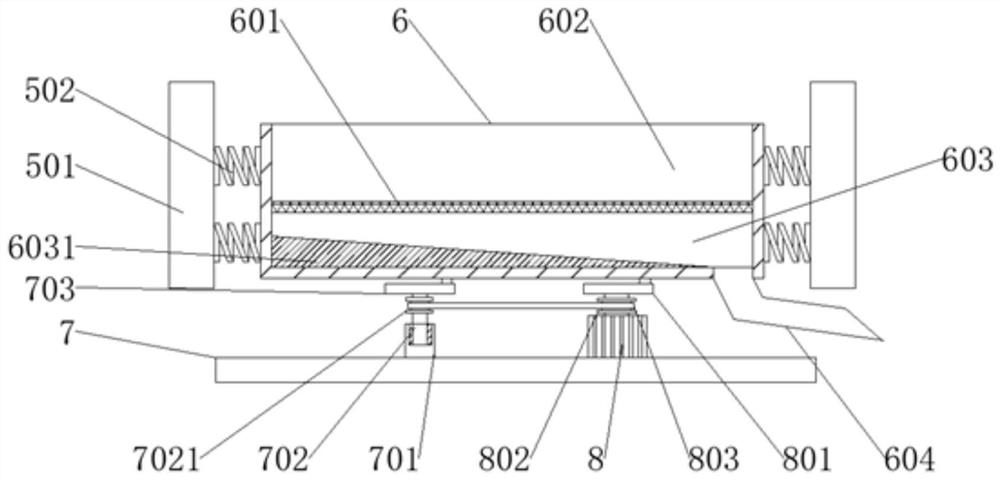

Vibration separation shiny-leaved yellowhorn shelling device

Owner:张掖市黄河农林牧科技有限公司

Dislocation refueling device

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

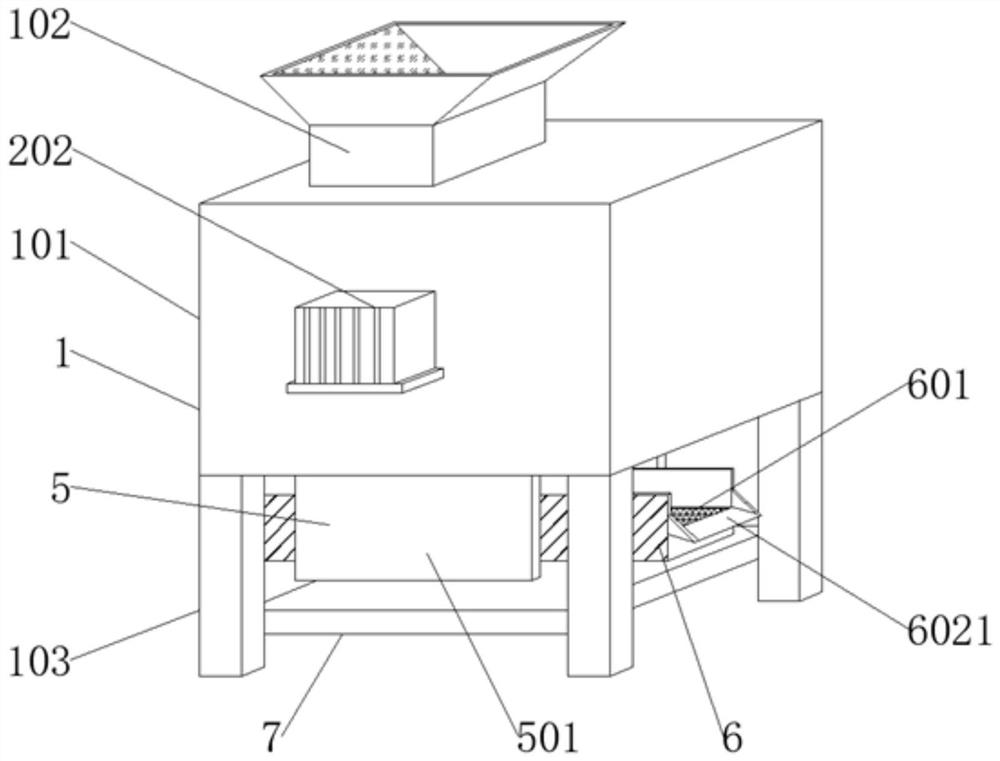

Drying device for aluminum products

The invention discloses a drying device for aluminum products and relates to the field of aluminum product processing. The drying device solves the technical problem of uneven drying of the aluminum products in the prior art. The drying device for the aluminum products comprises a box body and a conveyor belt connected into the box body in a penetrating manner. An air blower is connected to the box body. A heating pipe is arranged in the box body. The box body comprises an outer box body and an inner box body. Air inlet holes connected with the air blower are formed in the outer box body. Multiple vent holes are formed in the side wall of the inner box body. The drying device for the aluminum products is applied to drying of the painted aluminum products.

Owner:天门市燎原环保装饰材料股份有限公司

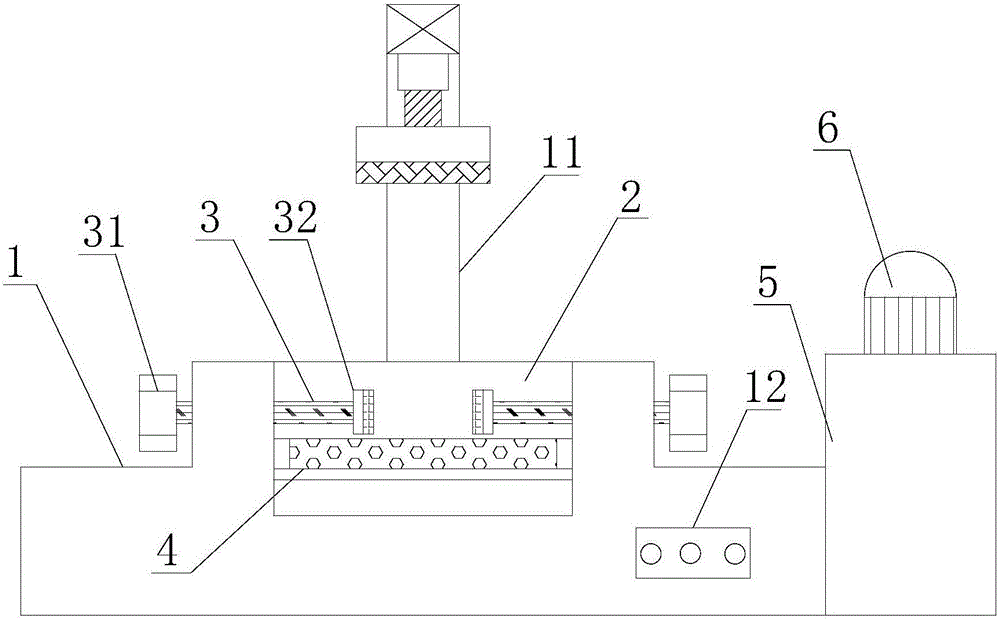

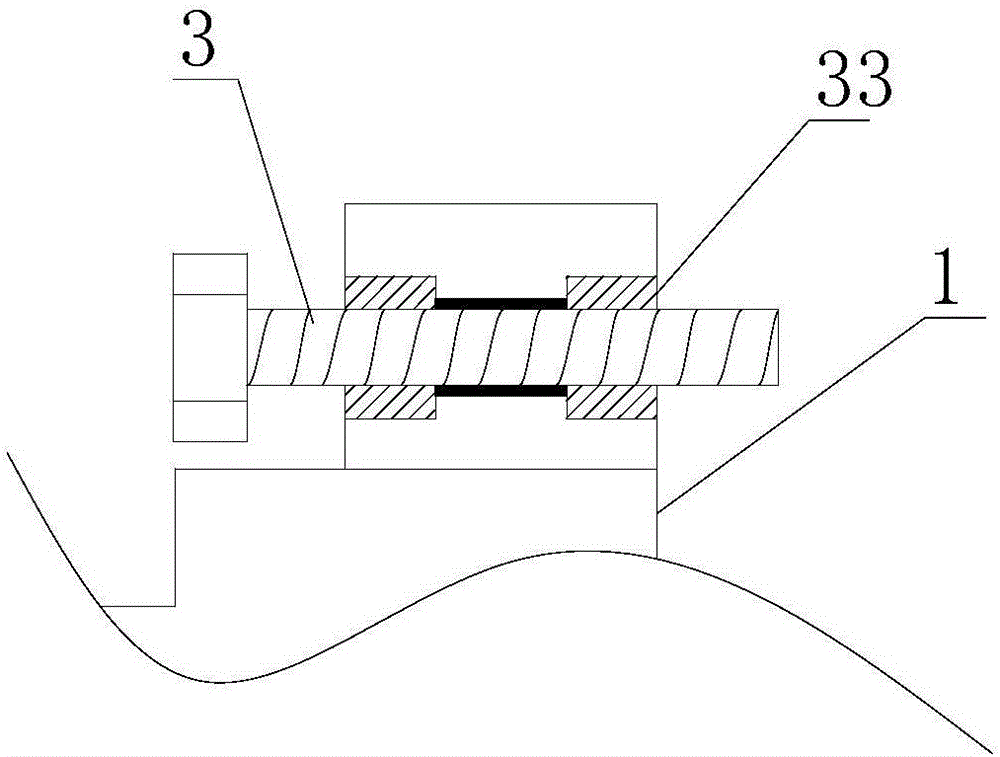

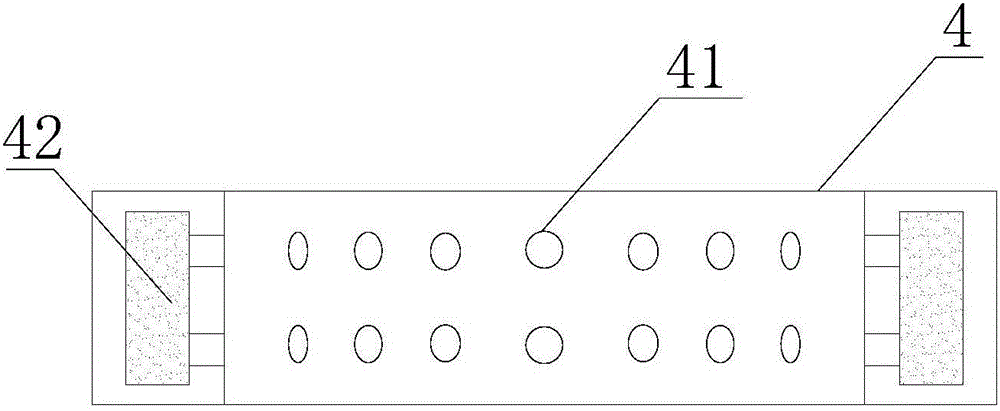

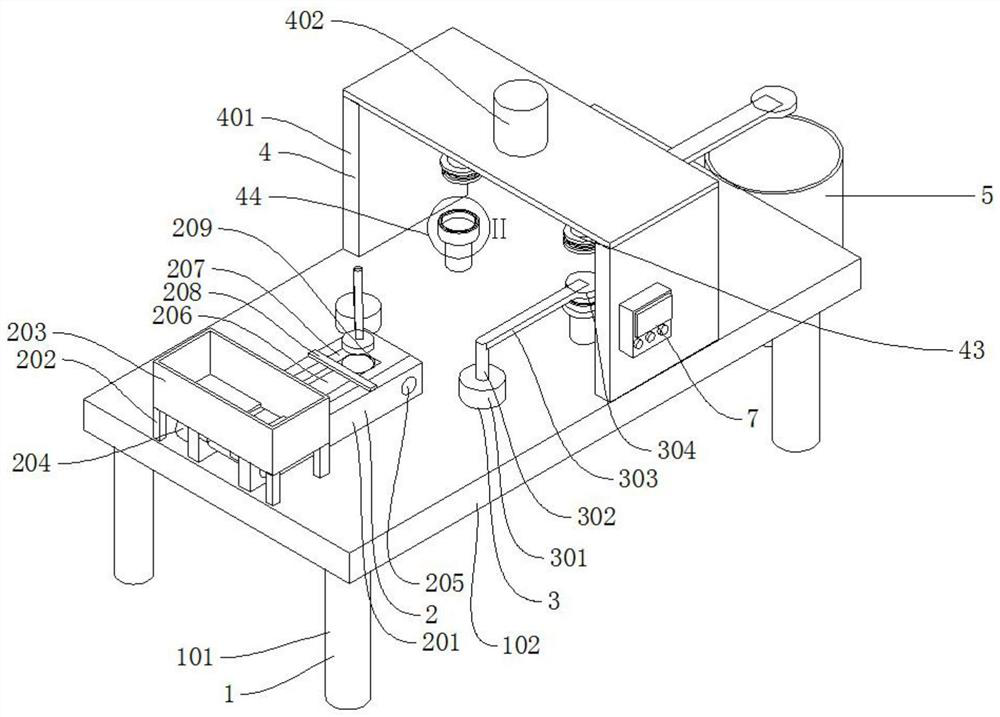

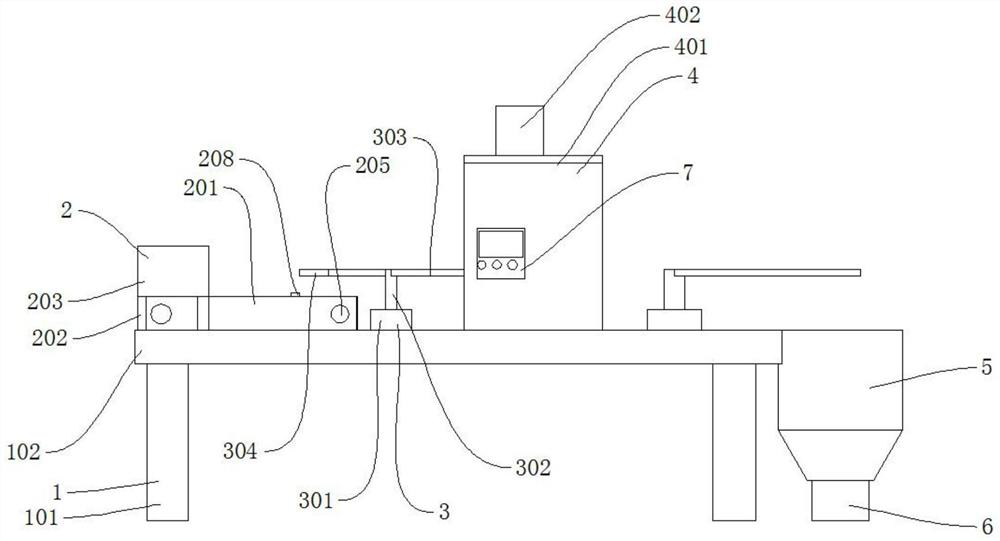

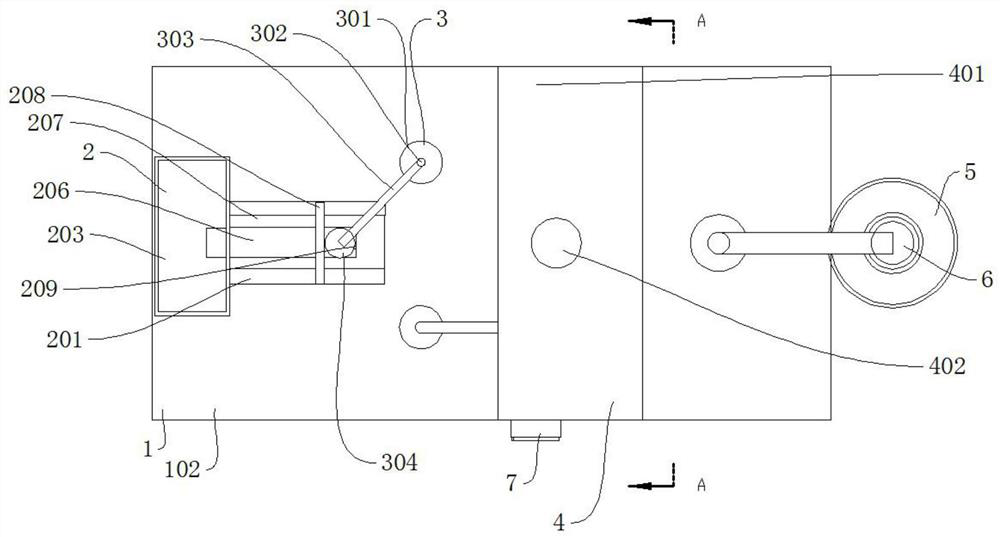

Impressing equipment for metal product processing and using method of impressing equipment

InactiveCN112238701AHas wait effectAvoid accumulationEmbossing decorationsElectric machineryProduct processing

The invention discloses impressing equipment for metal product processing and a using method of the impressing equipment. The impressing equipment comprises a supporting mechanism, a transferring mechanism, an impressing mechanism, a guiding barrel, a quantifying barrel and a control box.The supporting mechanism is composed of supporting legs and a working plate, and the impressing equipment further comprises a feeding mechanism. The feeding mechanism comprises a supporting frame, fixing rods, a storage box, a motor, a rotating shaft, a conveying belt, a limiting plate, a baffle and a first pressure sensor. The arrangement of the storage box is beneficial to placing a large number of materials at a time, the arrangement of the conveying belt is beneficial to conveying the materials, the arrangement of the limiting plate is beneficial to the sequential arrangement and transportation of the materials, the arrangement of the baffle ensures the position of the next material when the transferring mechanism adsorbs the materials, the whole feeding mechanism realizes the automatic sequential arrangement and transportation of the materials, a waiting effect is achieved, and accumulation orfalling is prevented.

Owner:浙江植言环境科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap