Automatic pipe feeding mechanism

A technology of automatic feeding and swing mechanism, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of safety production impact, product quality, and insufficient feeding, so as to improve processing speed and avoid industrial accidents , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

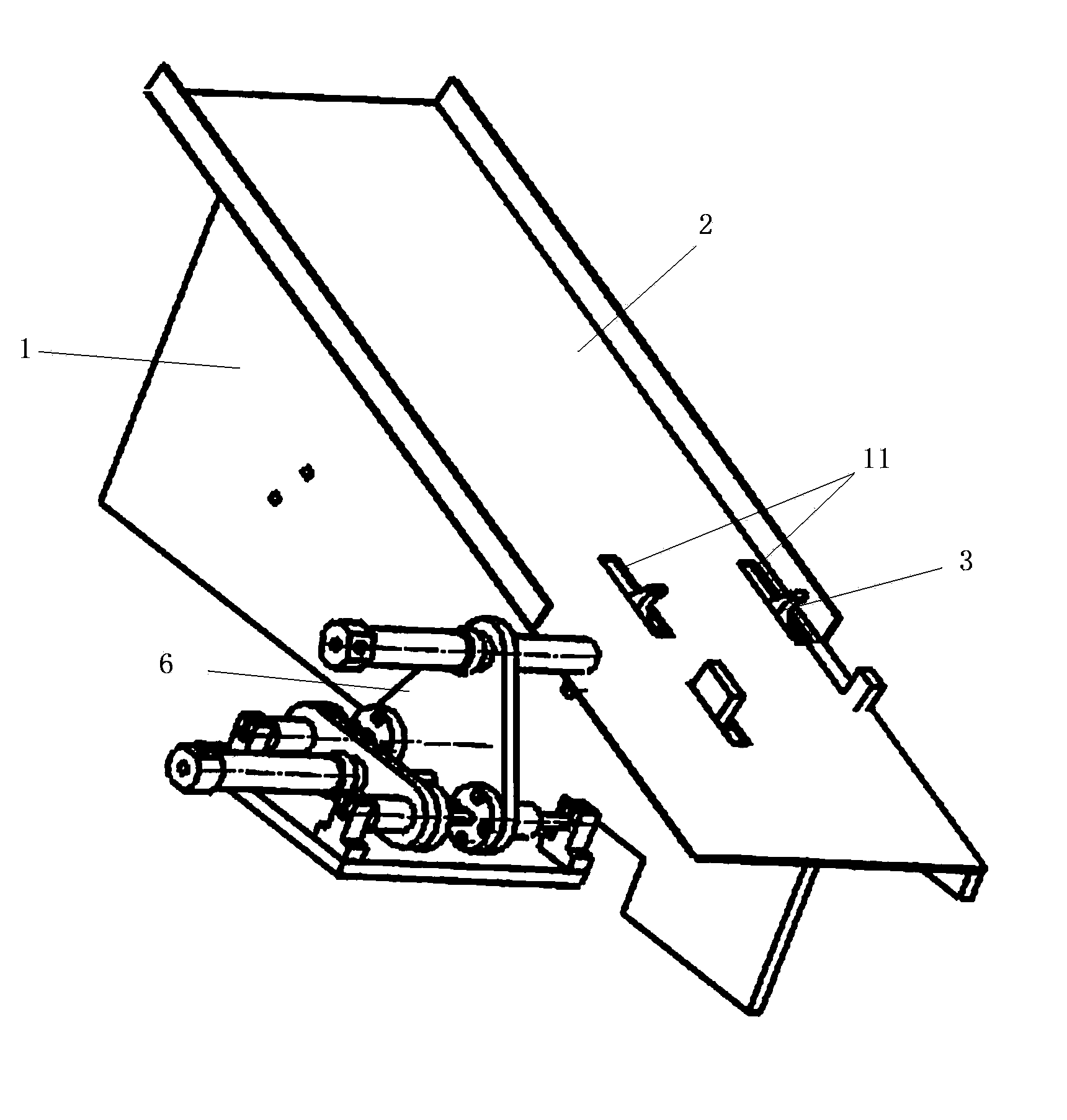

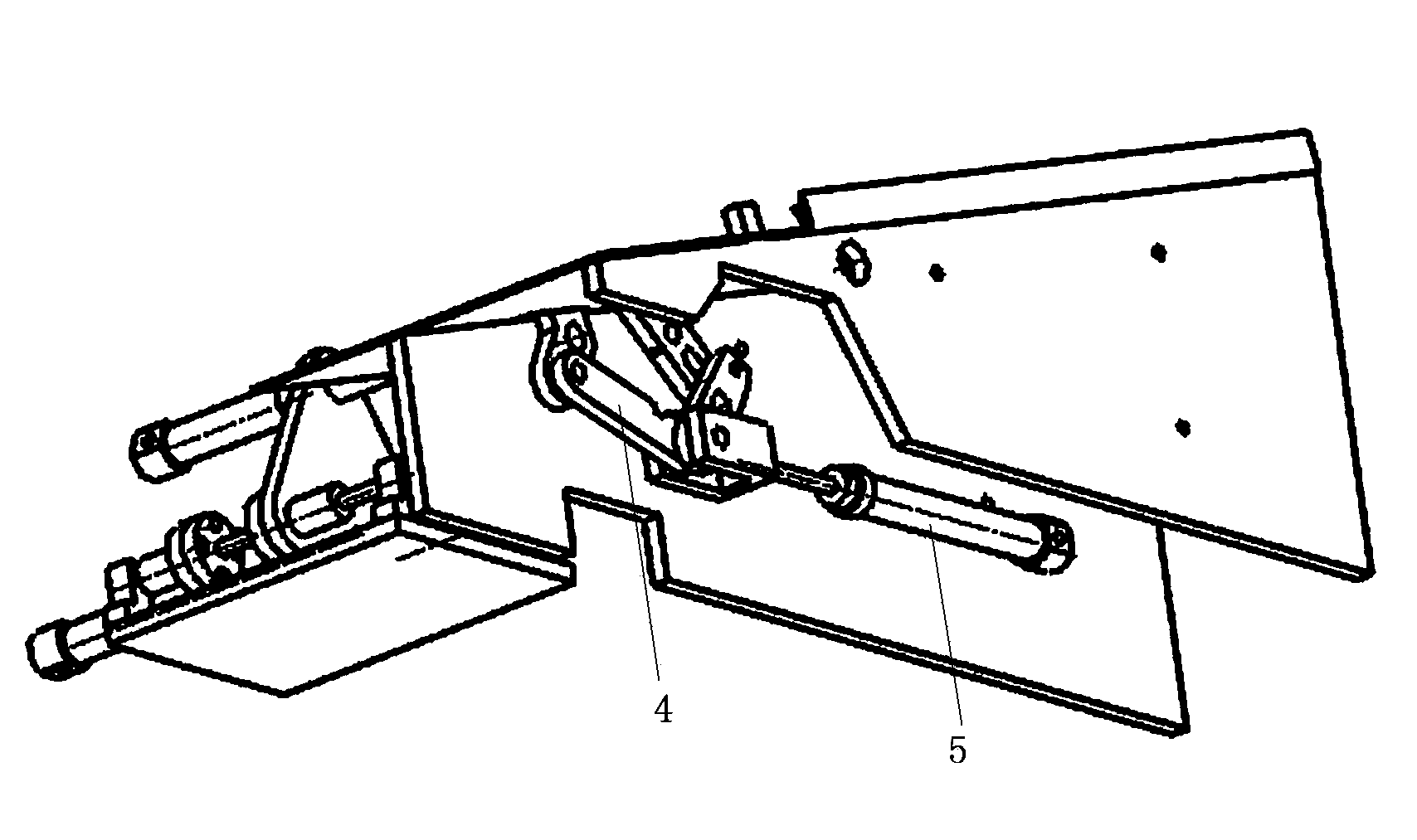

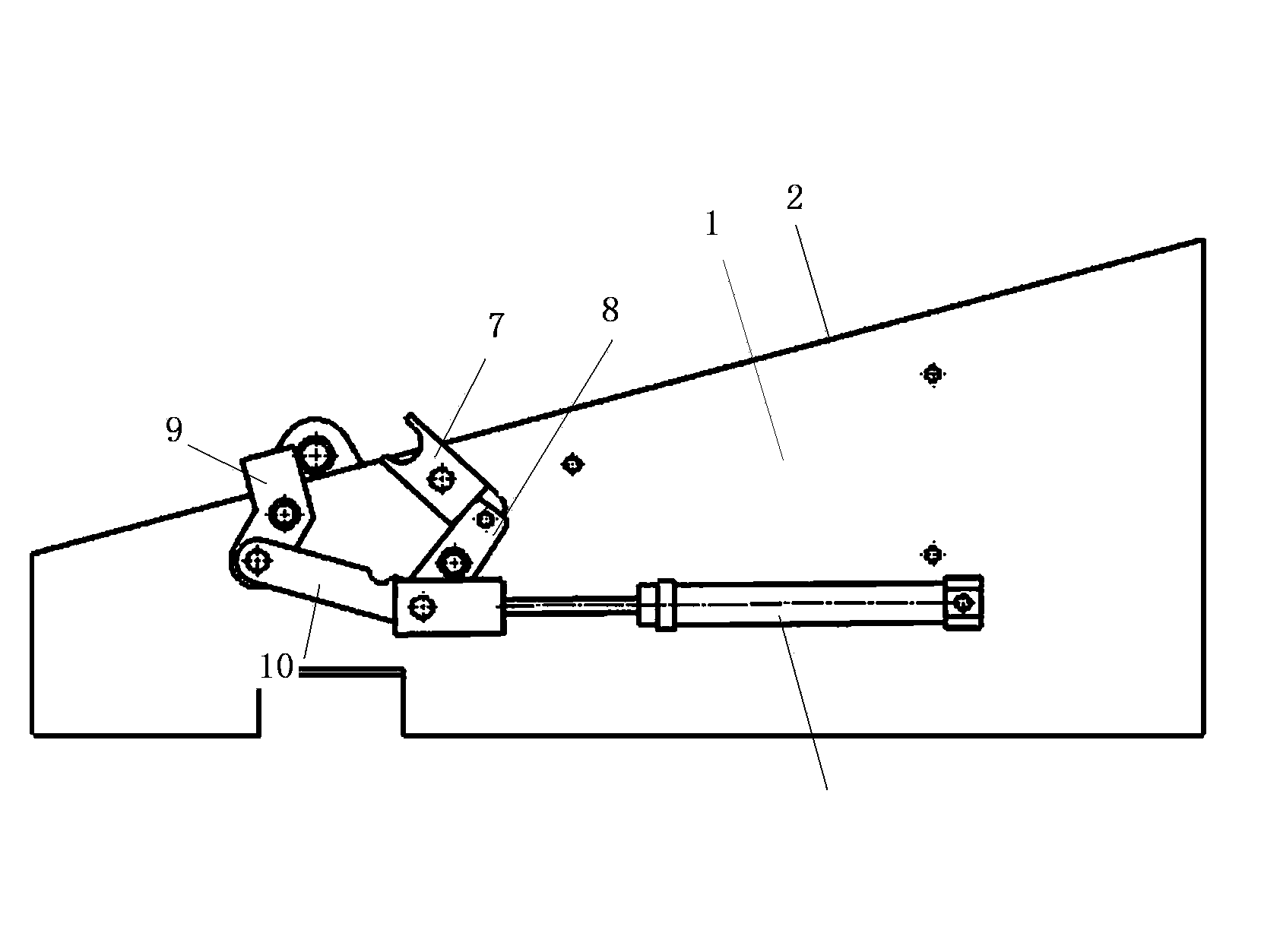

[0011] As shown in the figure, an automatic pipe feeding mechanism includes a frame 1, which is characterized in that the upper surface of the frame 1 is a swash plate 2, and a swing mechanism 3 is provided at the bottom of the swash plate 2. The swing mechanism 3 is connected to the cylinder 5 through the link mechanism 4, and a jacking mechanism 6 is provided at a position corresponding to the swing mechanism. According to a specific embodiment of the present invention, the oscillating mechanism includes a first oscillating block 7, the middle part of the first oscillating block 7 is rotationally connected with the frame 1, one end of the first oscillating block 7 is provided with an arc-shaped notch, and the other end is connected to the One end of the first connecting rod 8 is connected, and the other end of the first connecting rod 8 is connected with the push rod of the cylinder 5 . The swing mechanism also includes a second swing block 9, the middle part of which is rotati

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap