Dislocation refueling device

A station and positioning seat technology, applied in the field of automation equipment, can solve problems such as low stability, reliability and safety, lower product competitiveness, and unfavorable production control, so as to facilitate production control, prevent product crushing, and save energy. The effect of manpower and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

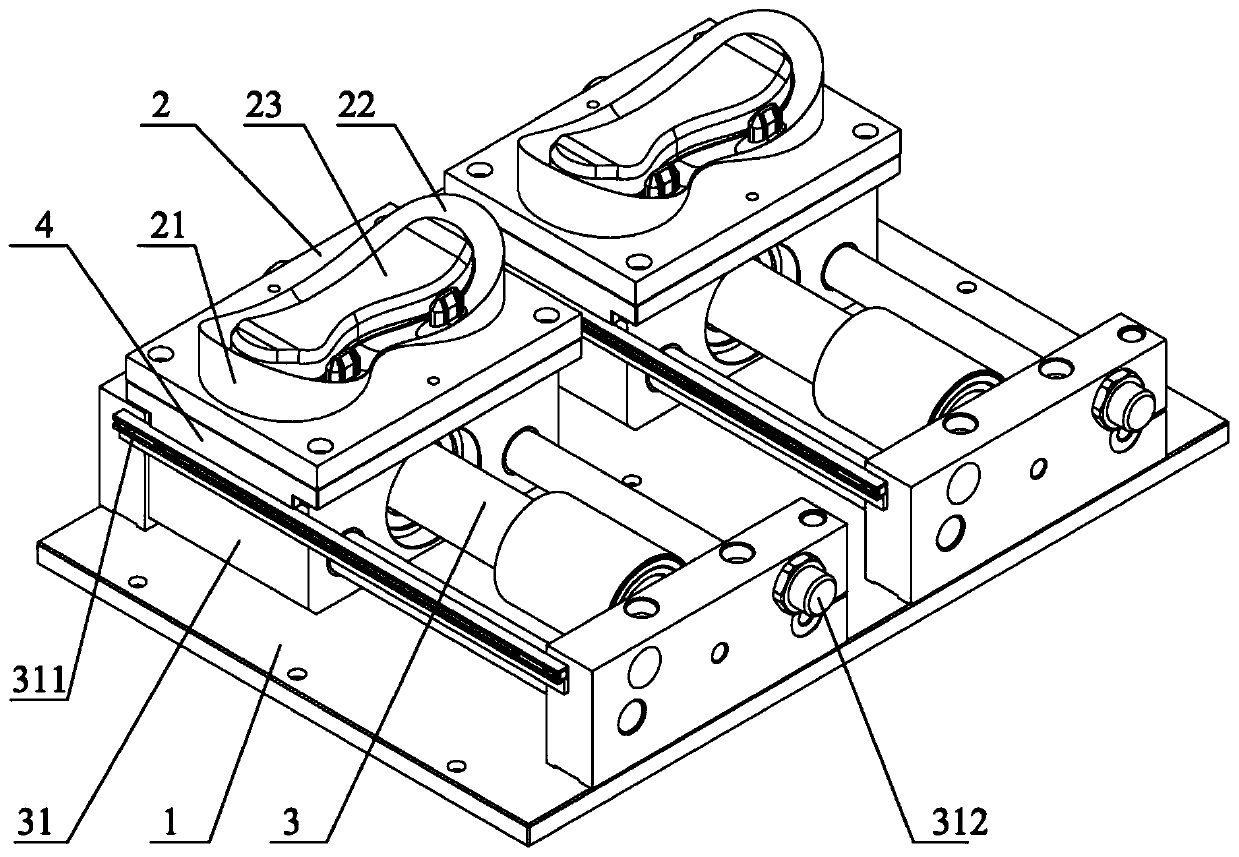

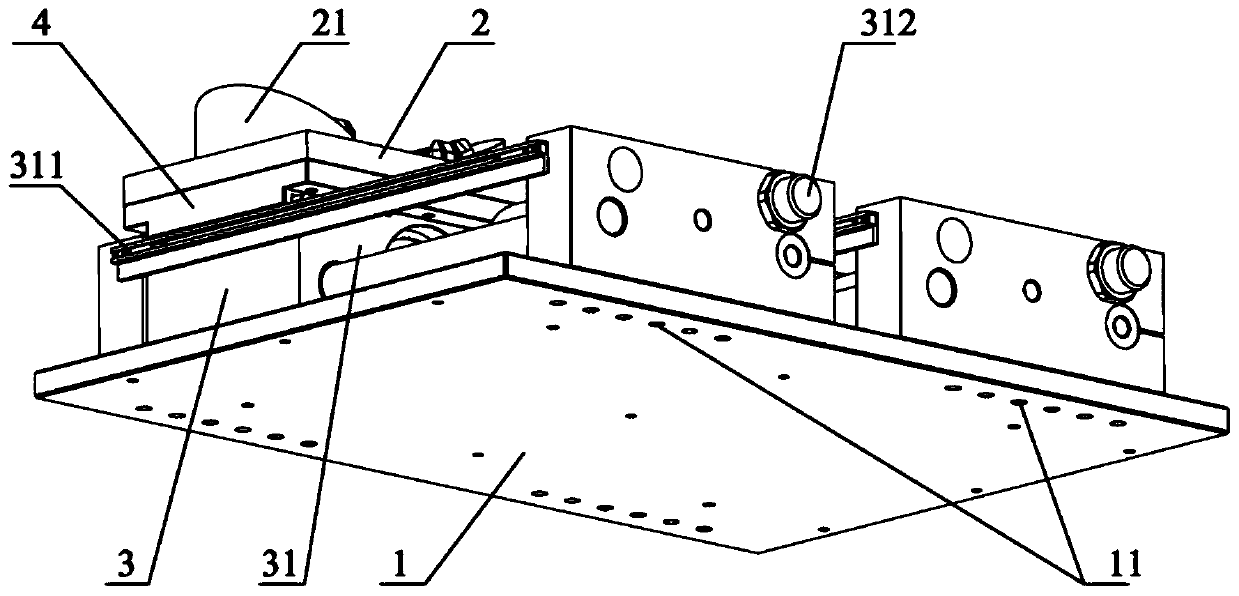

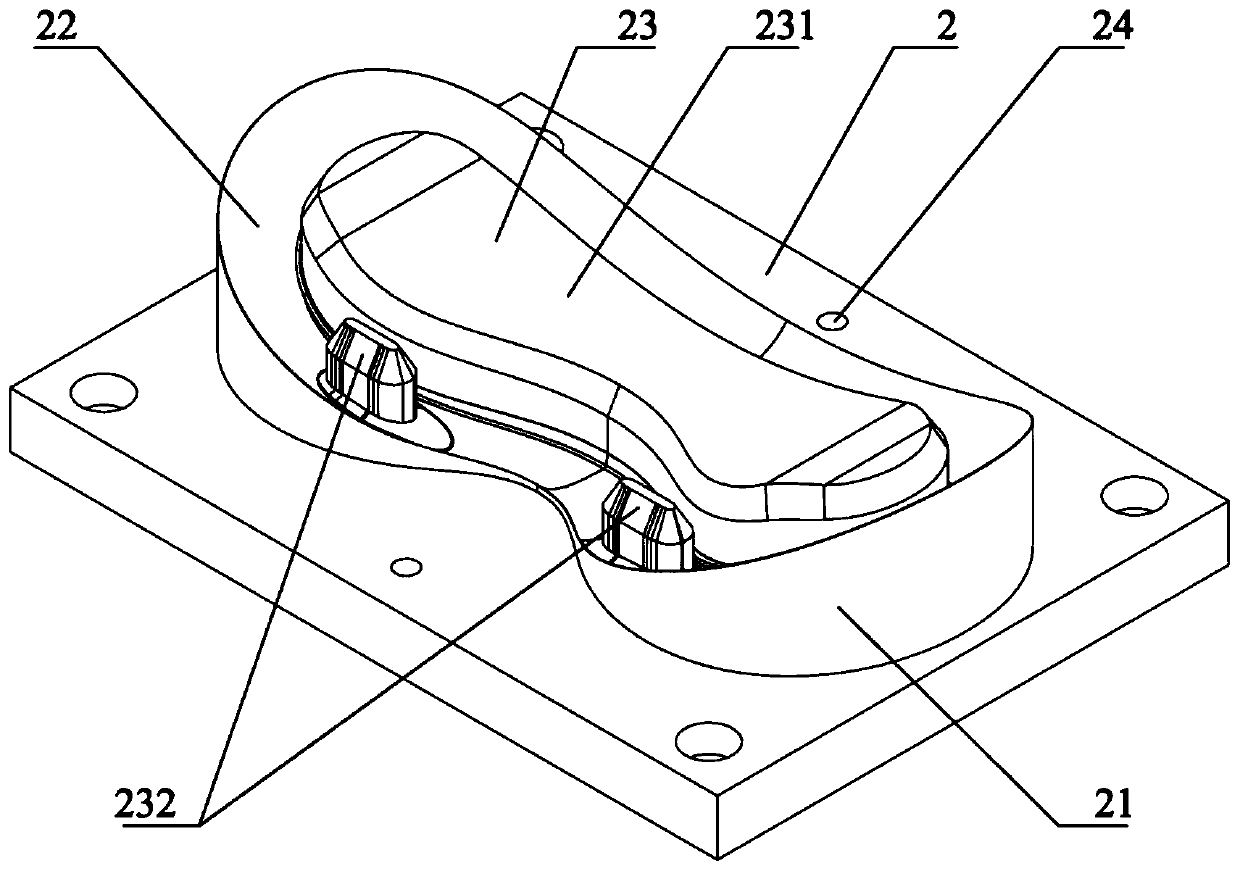

[0030] Such as Figure 1~5 As shown, a staggered refueling device is mainly used for compression nut equipment. The staggered refueling device includes a bottom plate 1. The bottom plate 1 is used to install at the corresponding position of the compression nut equipment. The bottom plate 1 is provided with two positioning seats 2 and Two linear motion mechanisms 3 that drive the two positioning bases 2 to reciprocate linearly, and the two linear motion mechanisms 3 are arranged side by side. The positioning base 2 is provided with a positioning table 21 for positioning and placing products, and the positioning table 21 is provided with The profiling groove 22 matched with the product is provided with a profiling table 23 for matching with the product. Usually the lower end of the product is placed in the profiling groove 22, and the profiling groove 22 can drag The product is positioned to support the product, and the cavity and hole of the product cooperate with the profiling tab

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap