Method for preparing corrugated paper

A technology for corrugated paper and corn starch, applied in the field of pulp and paper making, can solve the problems of not being able to improve the strength of corrugated paper well, and achieve the effect of strength enhancement and improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

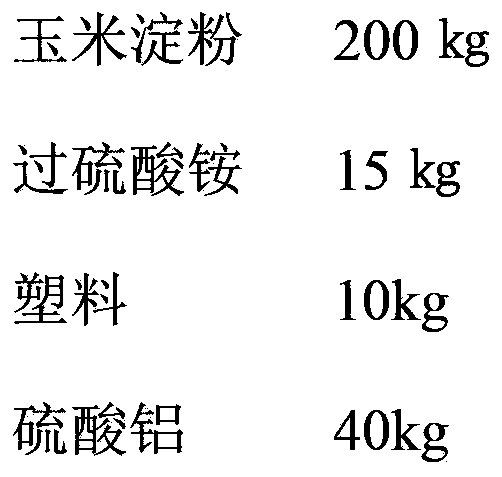

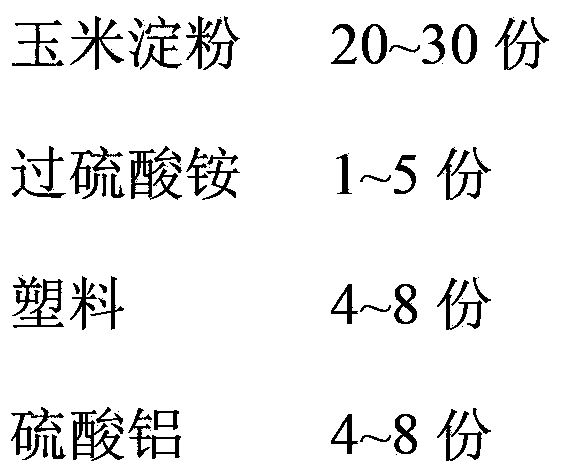

[0020] A kind of preparation method of high-strength corrugated paper, its raw material composition and proportioning composition are respectively:

[0021]

[0022] Its preparation steps are:

[0023] (1) Screening: Screen the cornstarch with a fineness of at least 98 mesh;

[0024] (2) Pulping: add 800kg of water to the reaction kettle, keep the temperature at 70°C to 85°C, stir and add the screened starch, and mix evenly to obtain corn starch slurry;

[0025] (3) Thickening: Stir and add ammonium persulfate into the cornstarch slurry, mix well, heat up to 85°C-95°C, and keep the temperature for 7-15 minutes;

[0026] (4) Adding materials: melt the ABS first, then add the melted ABS to the thickened cornstarch slurry, the ratio of its volume to the thickened pulp is 1:50;

[0027] (5) Water-resistant treatment: Dissolve aluminum sulfate in water to obtain an aluminum sulfate solution with a mass fraction of 10%. Add the aluminum sulfate solution to the thickened corn pulp,

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap