Preparation method of residual-sludge-based particle electrode carrier

A technology of excess sludge and particle electrodes, applied in chemical instruments and methods, water/sludge/sewage treatment, clay products, etc., can solve the problem of low utilization rate of excess sludge, and achieve catalyst loading and pore types Enrichment, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

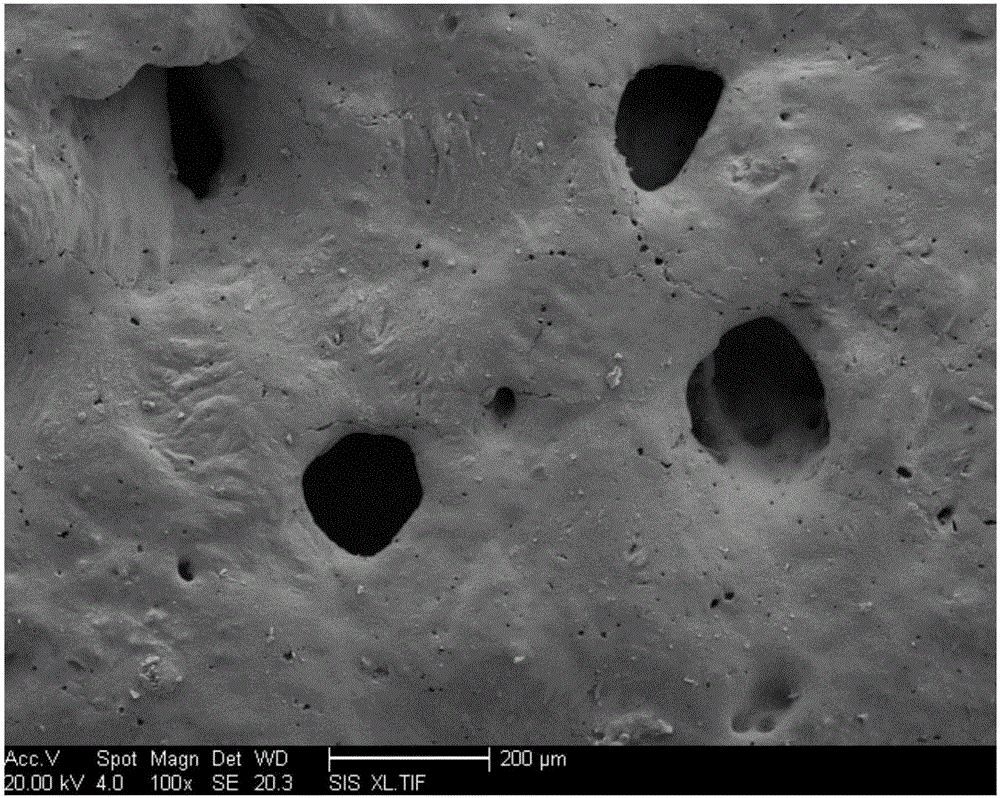

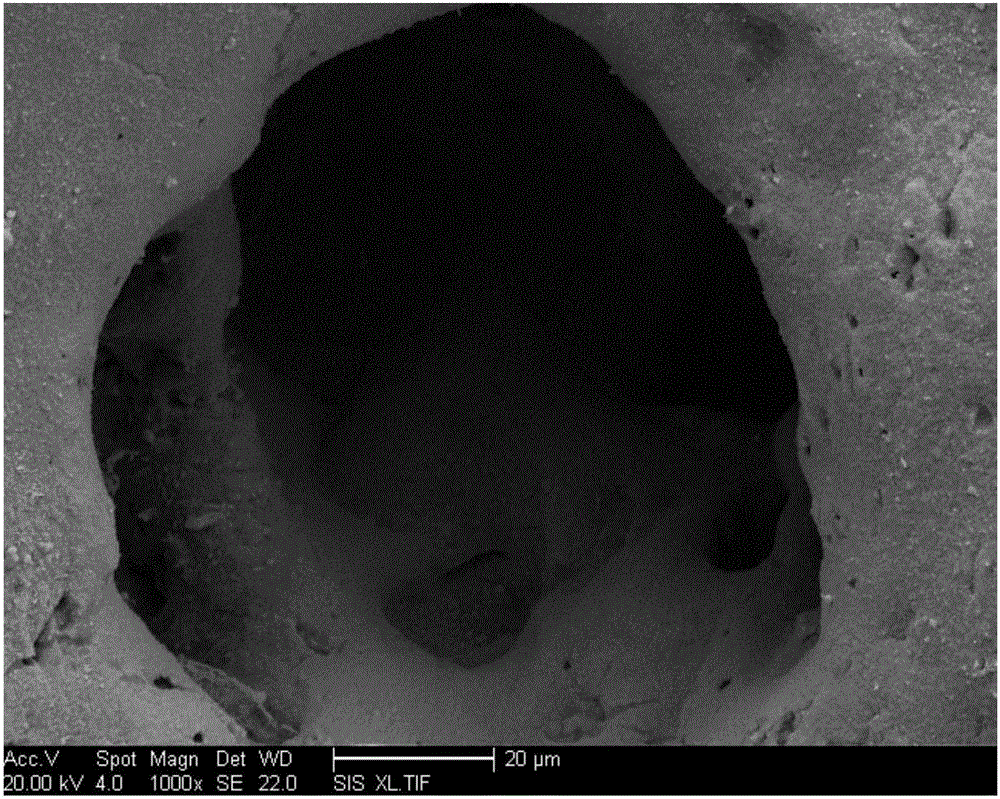

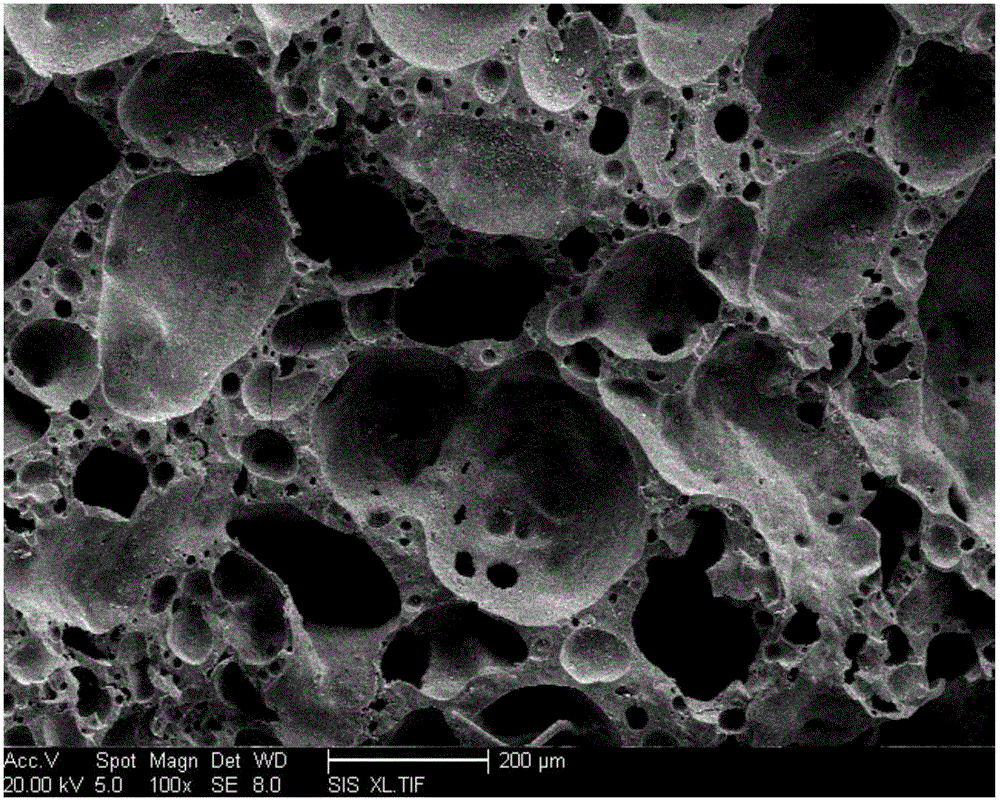

[0021] Embodiment 1: In this embodiment, a method for preparing a surplus sludge-based particle electrode carrier is specifically carried out in accordance with the following steps:

[0022] 1. Dry the remaining sludge after mechanical dehydration to dry sludge, then pulverize it, and sieve it through a sieve with an aperture of 100 mesh to obtain dry sludge powder;

[0023] 2. Mix the absolute dry sludge powder and montmorillonite obtained in step 1 evenly, then add water and stir to make raw meal balls, and then dry at room temperature;

[0024] 3. Put the raw meal balls treated in step 2 into a muffle furnace to preheat, then raise the temperature to the roasting temperature, roast, and then cool to obtain the remaining sludge-based particle electrode carrier.

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, the drying temperature is 105° C., and the drying time is 24 hours. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 1, a pulverizer is used for pulverization, and the pulverization time is 1 min. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap