Method for preparing nitrogen/carbon-containing material by biomass pyrolysis and carbonization

A biomass pyrolysis and nitrogen-carbon material technology is applied in the field of nitrogen-containing carbon material preparation to achieve the effects of simple and easy production process, soil improvement, and suitability for large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

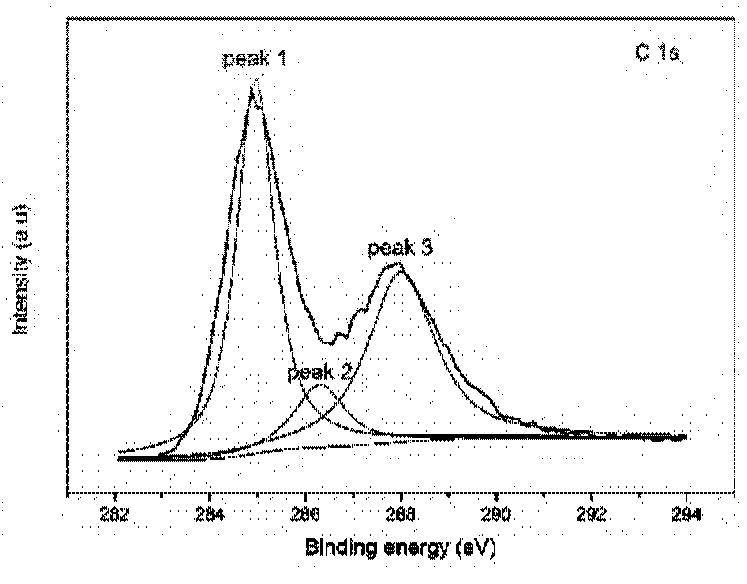

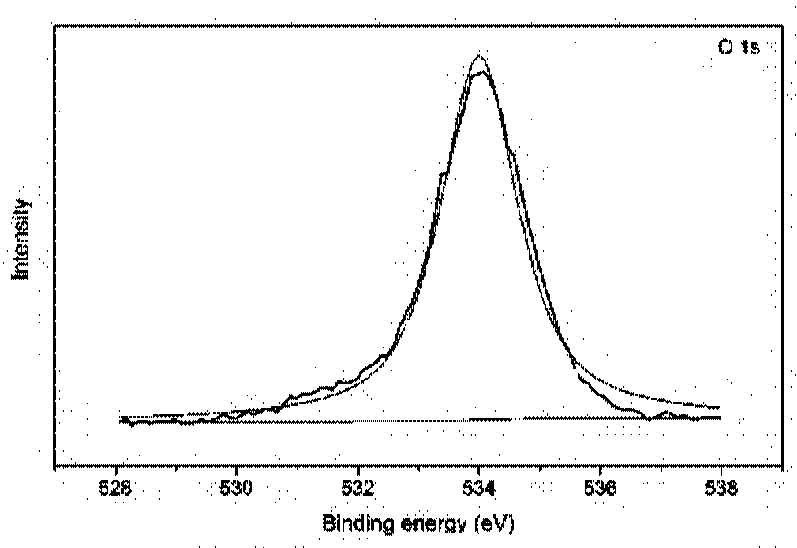

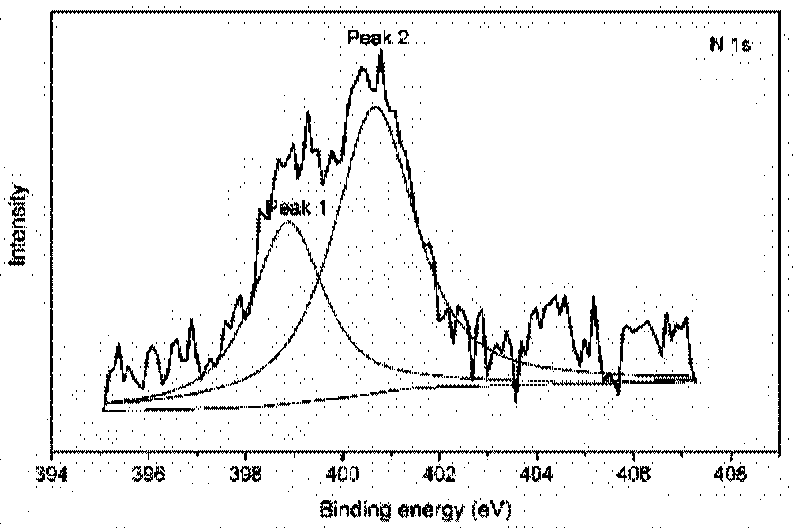

Image

Examples

Embodiment 1

[0031] In this example, a quartz tubular reactor with a diameter of 34 mm and a length of 300 mm was used, and the heating part in the reactor was isolated with quartz wool. Install the quartz reactor in a temperature-controlled furnace. During operation, ammonia gas was used as a carrier gas, and its flow rate was controlled by a gas flow meter. The carrier gas used in this experiment was NH 3 or NH 3 / N 2 , NH 3 / He mixture. The reaction raw materials and the catalyst are evenly mixed and flow together with the carrier gas flow from the opening of the quartz tube to the pyrolysis interface. The liquid product flows from the reactor to the condenser, the gas product is collected in a gas sampling bag, and the solid product is supported by quartz wool. After the reaction is complete, the catalyst and the solid product produced by the reaction are separated and collected and weighed. The separated solid product is nitrogen-containing biomass carbon material. In this exa

Embodiment 2

[0034] In this example, 6 different catalysts were tested for the catalytic pyrolysis of cellulose, including: γ-Al 2 o 3 , SiO 2 -Al 2 o 3 , SnO 2 / SO 42- , MCM-41, HZSM-5. The powdered reactant was prepared by physically mixing carbohydrate feed and catalyst. In this experiment, the ratio of catalyst to bagasse was 2, the reaction temperature was 550°C, and the gas flow rate was 200ml / min. The pyrolytic carbonization time is 0.5h. The catalyst is mixed with cellulose and ground into powder.

[0035]

[0036]

Embodiment 3

[0038] In this example, the influence of different catalysts to biomass ratios on nitrogen-containing biomass carbon materials is tested. The catalyst in this experiment is γ-Al 2 o 3 , the reaction temperature is 550°C, the gas flow rate is 200ml / min, and the pyrolysis carbonization time is 0.5h. The catalyst is mixed with cellulose and ground into powder.

[0039]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap