Biomass hydrolyzing process of preparing reductive monosaccharide

A biomass raw material, biomass technology, applied in the direction of monosaccharides, etc., can solve the problems of long hydrolysis cycle, high cost, large equipment investment, etc., and achieve the effect of reducing demand and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

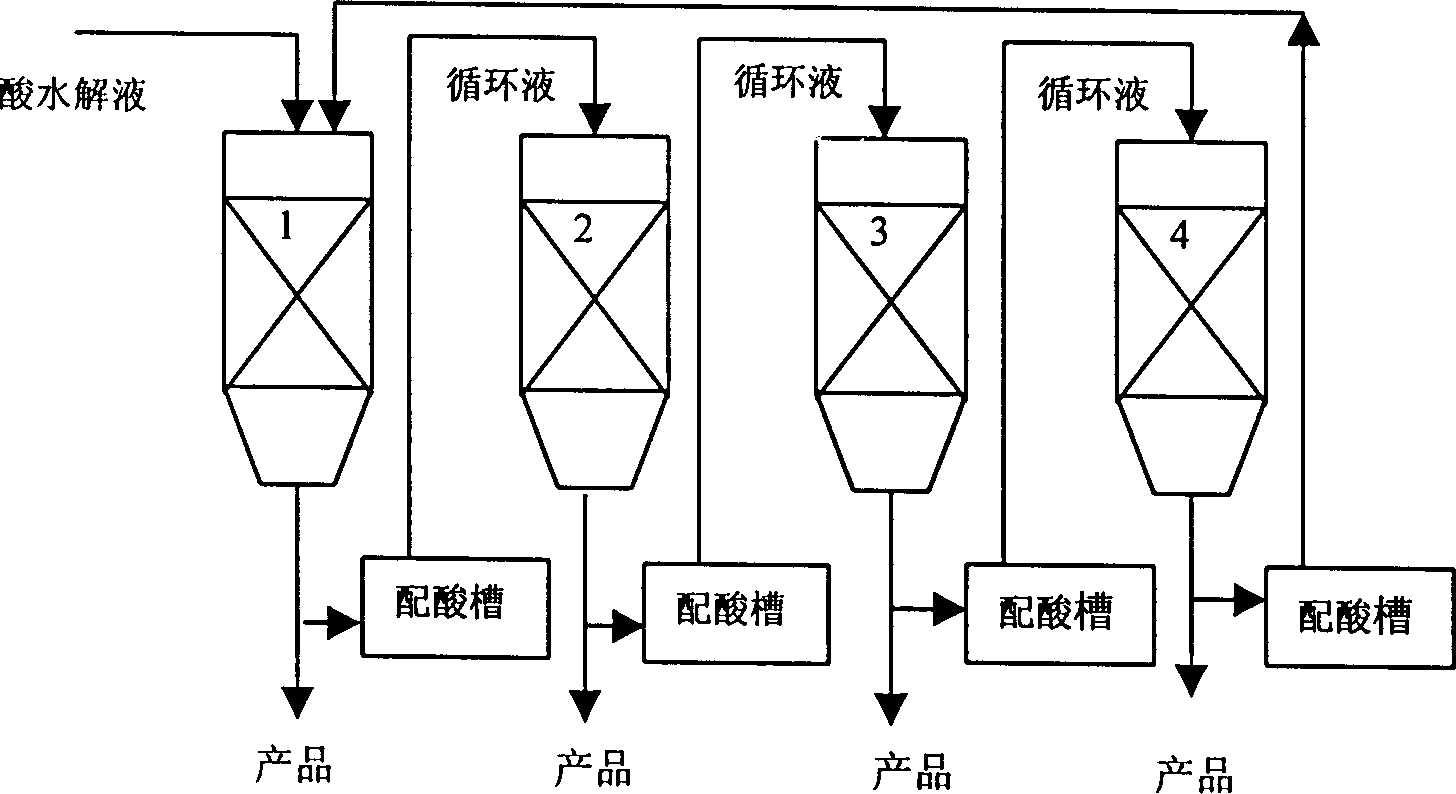

Embodiment 1

[0028] Add 400 grams of biomass raw material in the hydrolysis reactor; with 3wt% HCl and 1wt% FeCl 2 The aqueous solution is a hydrolyzate, which is added to the acid tank, pressed into the hydrolysis reactor by high-pressure nitrogen, and heated to 110°C by means of external electric heating, and the collection begins. The resulting solution is marked as I, volume It is 1620ml. Then the reaction temperature was raised to 160° C., and the second collection was made. The resulting solution was marked as II, and the volume was 3130 ml. The washing liquid collected after washing the hydrolyzed residue is marked as III and has a volume of 1960 ml. The hydrolysis reaction time is 20 minutes from the time when the temperature rises to 110° C. to the completion of the second part of the collection. Solution I is the product of this hydrolysis, and its sugar concentration is 3.5wt%. Solution II and washing solution III are used as circulating fluid to participate in the hydrolysis of

Embodiment 2

[0030] In addition to adding 83ml of concentration to be 9.86mol / LHCl and 10ml13wt%FeCl in the circulation liquid obtained by embodiment 1 through the acid tank 2 Except for the aqueous solution, other process conditions are the same as in Example 1, and the concentration of sugar in the product obtained is 5.5 wt%.

Embodiment 3

[0032] In addition to adding 83ml concentration of 9.86mol / LHCl and 9ml13wt%FeCl in the circulating liquid obtained by embodiment 2 through the acid tank 2 Except for the aqueous solution, other process conditions are the same as in Example 1, and the sugar concentration in the product obtained is 6.1wt%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap