Equipment and a method for generating biofuel based on rapid pyrolysis of biomass

Inactive Publication Date: 2011-09-15

UNIV DE CONCEPCION

View PDF17 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

These heat transfer problems are central to any successful development that requires extreme operation conditions in the pyrolysis reactor.

The problem presented by using an overheated particulate material as the only heat source is that said material must be heated well over the optimal pyrolysis temperature in order to supply the heat amount required for the pyrolysis reactions.

This causes that when the organic material enters into contact with the overheated inert material, the former can be partially gasified and the generation of condensable vapors can be impaired, which lowers the biofuel yield.

Additionally, all the previous patents use recycling fluidized bed systems in which all the p

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

application example

Radiata pine sawdust containing 11.3% of moisture content and having a size lower than 3 mm was pyrolyzed under the following conditions:

Temperature520° C.Mean reaction time of the solid4 secResidence time of the vapors3 secFeeding rate35 kg / h

Pyrolysis vapors were quickly condensed to produce a biofuel that represented 68.3% of the initial mass; a pyrolysis gas with 13.5% of the initial mass and fine charcoal less than 1.5 mm with 18.2% of the feed mass by weight.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

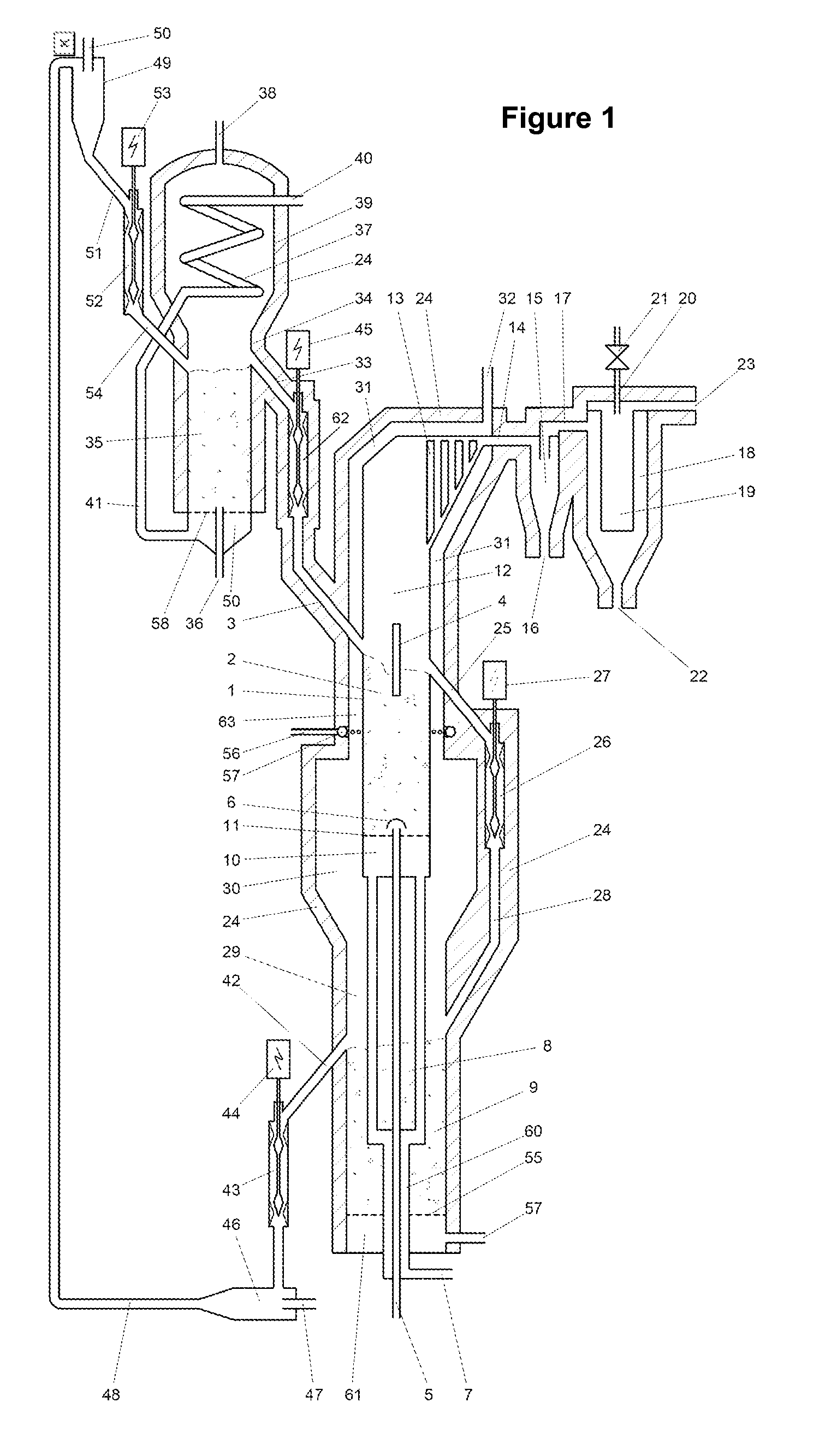

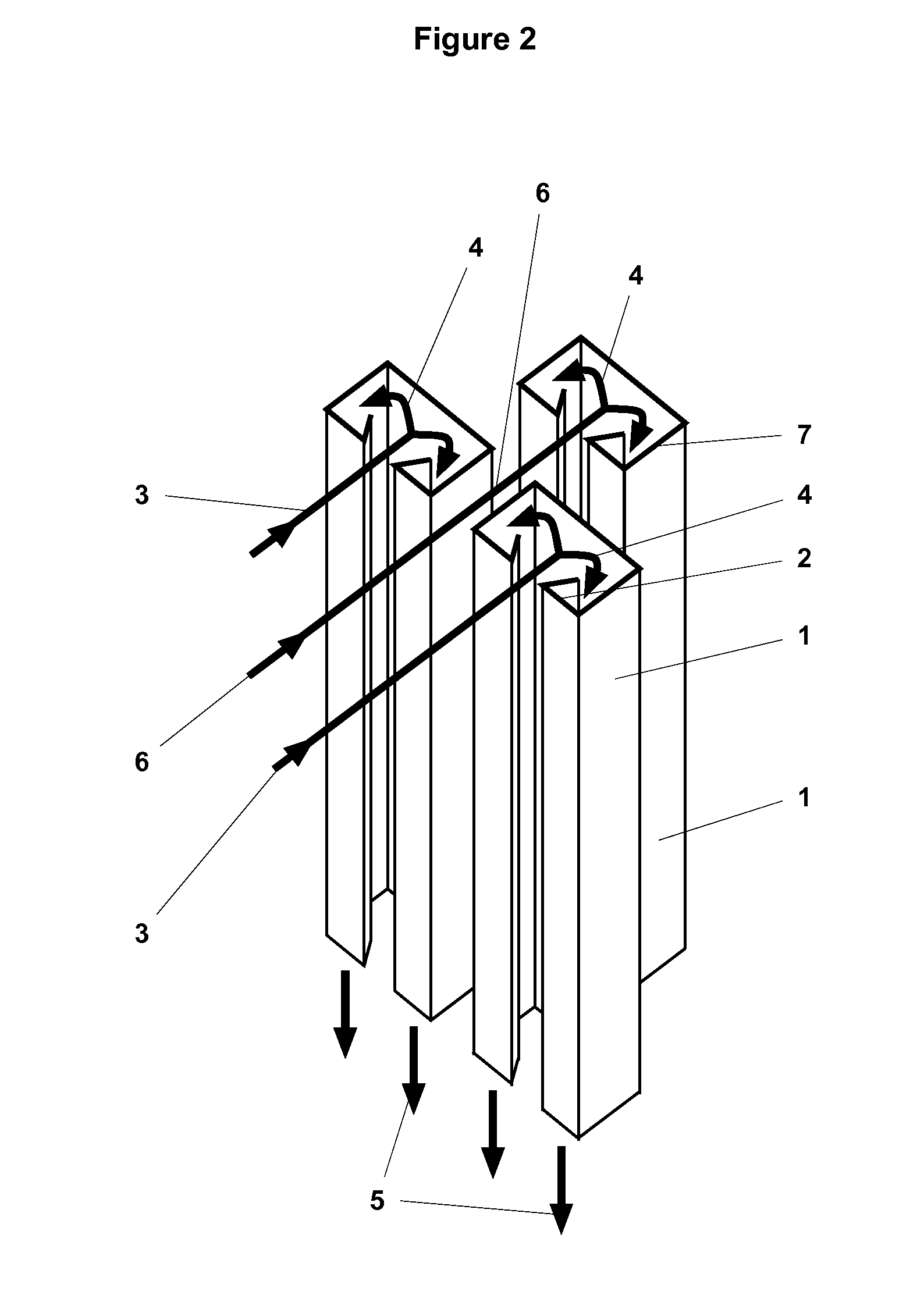

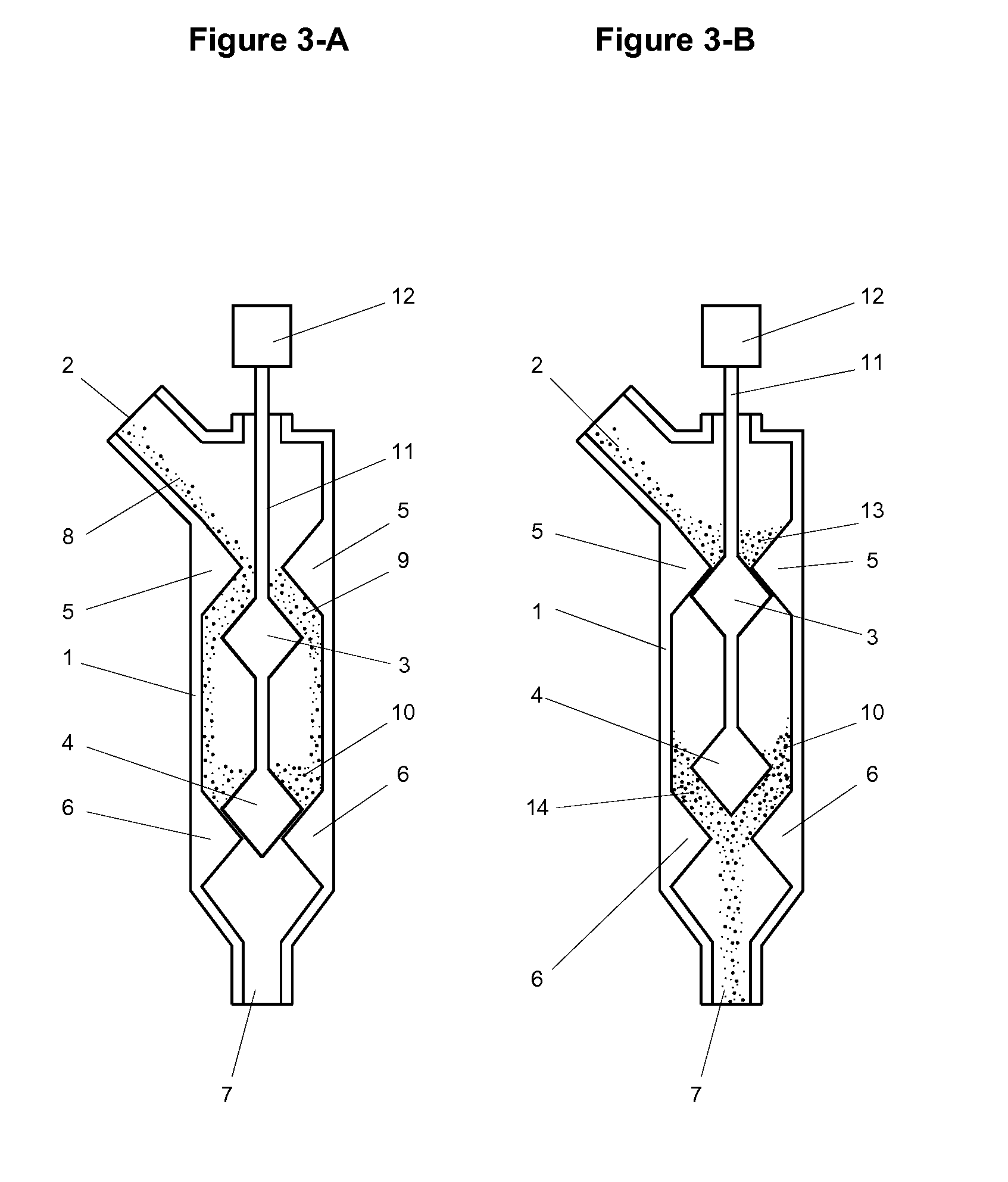

Equipment and a process to produce biofuel by fast pyrolysis of organic material, comprising a system of three interconnected serial fluidized bed reactors: a fast pyrolysis reactor located inside another reactor wherein charcoal is burned; a combustion reactor that burns the charcoal generated in the fast pyrolysis reactor; and a preheating reactor to preheat inert particulate material. The equipment also includes a pneumatic recycling system for inert particulate material.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Owner UNIV DE CONCEPCION

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap