Controlled surface topography for enhanced protein crystallization rates

a technology of enhanced protein and controlled surface topography, which is applied in the direction of crystal growth process, immunoglobulin, peptides, etc., can solve the problems of difficult to integrate porous materials in bulk form with current testing systems and equipment, and the process of obtaining a protein crystal can be costly and inefficient, so as to prevent uncontrolled evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

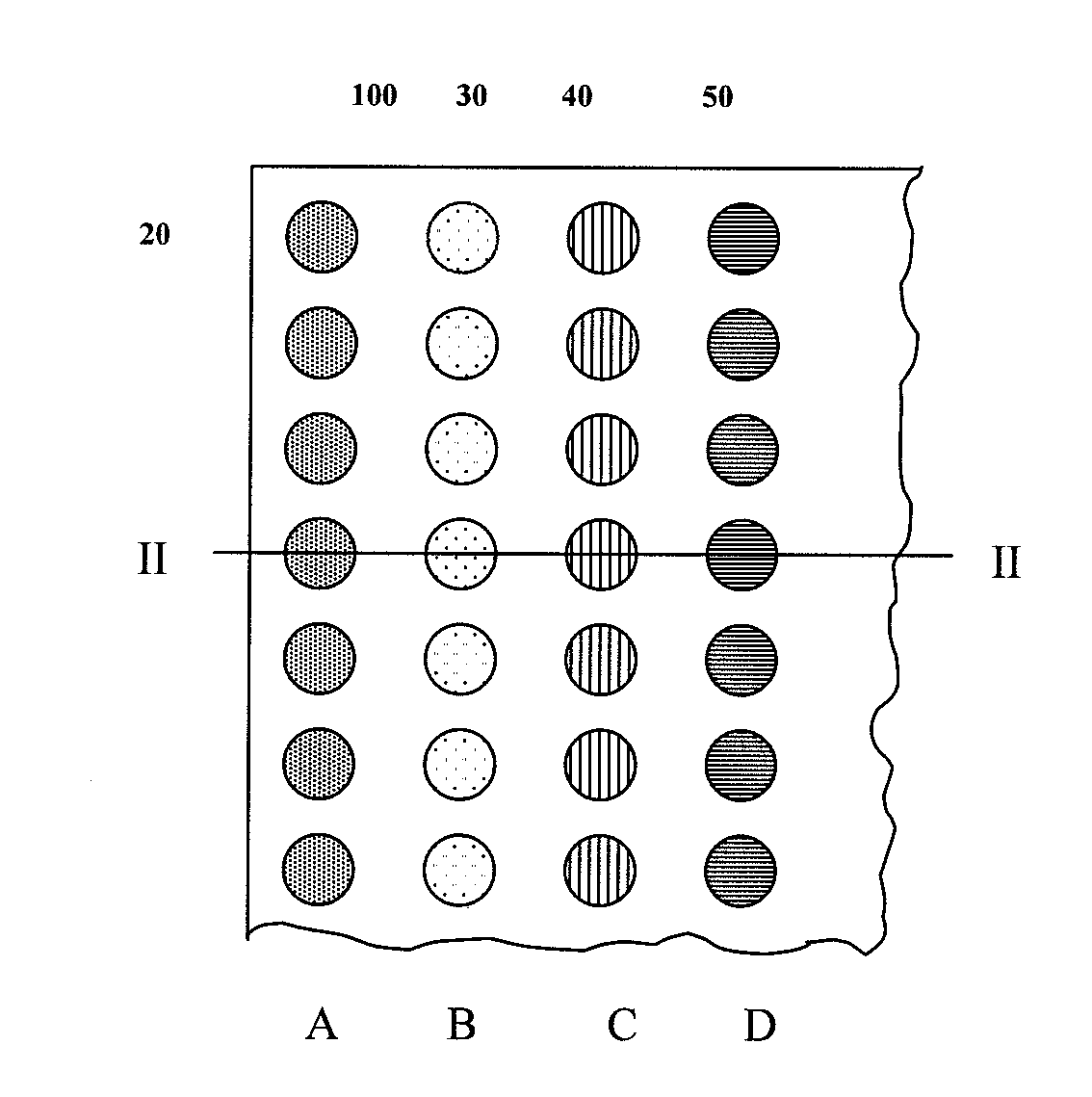

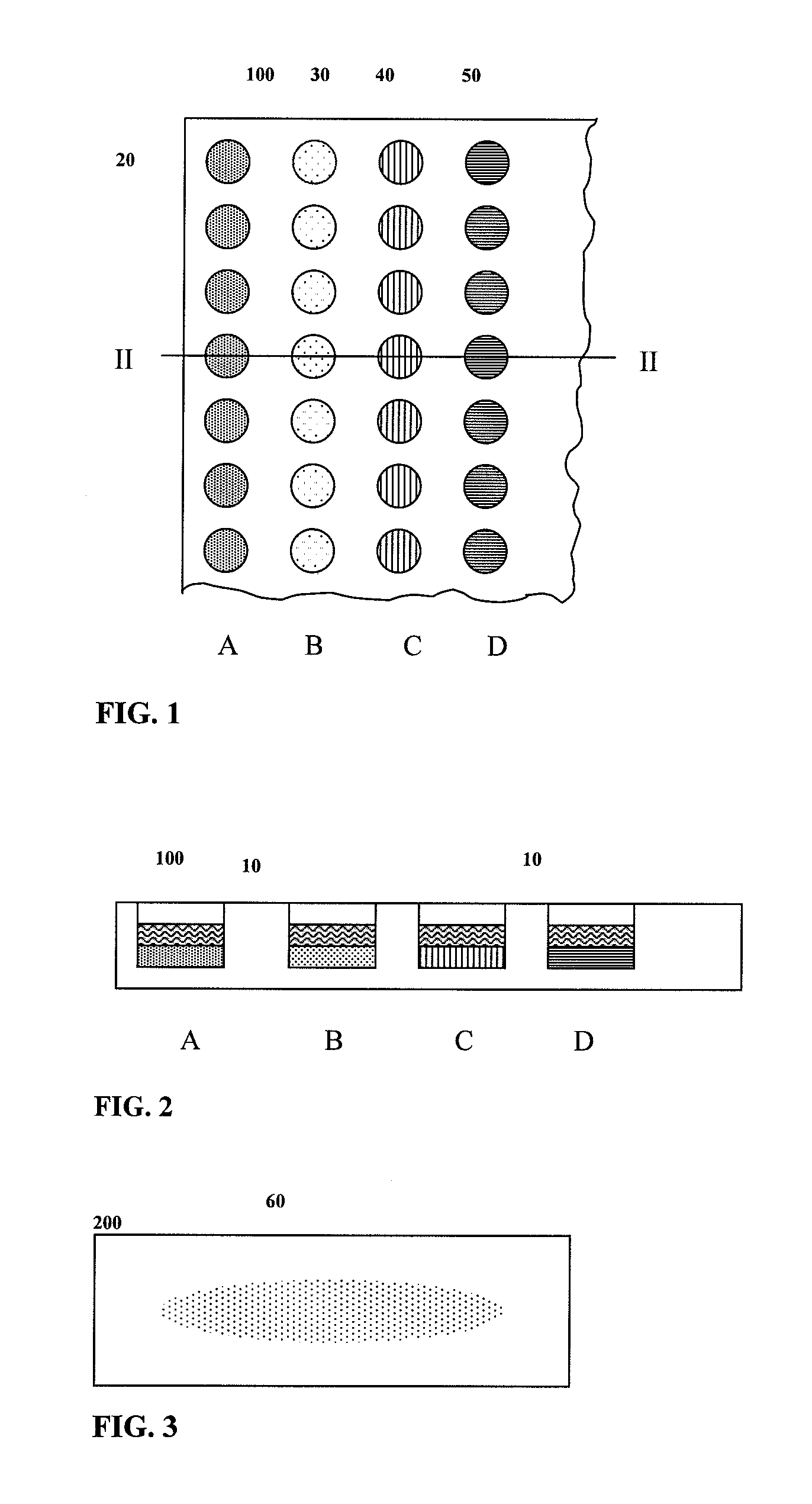

[0046]FIG. 1 is a partial schematic diagram of a preferred embodiment of the invention, showing a plurality of different types if colloidal particles deposited onto the bottom inner surface of a well within a micro-titer plate for protein crystallization thereon.

[0047]A plate 100 containing a plurality of wells, for example, 96 wells, is provided, and each column (or row) is coated by a unique coating material. For example, the wells 20 in column A are provided with a silica coating, whereas the wells 30 in column B are coated with zirconia. The column or rows can be coated so that alternating ones have different coatings or repeating patterns of the same coating materials.

[0048]As shown, the wells 40 and 50 in columns C and D are also coated with different coatings, such as alumina or other suitable coating materials described above. Using several different types of coatings on a single plate as shown here provides a format that allows for higher throughput screening of possible prote

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap