Clamshell and small volume chamber with fixed substrate support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

The following examples will now reveal additional details and features concerning embodiments of the processing chamber. The following examples should not be construed to limit the scope of the invention unless expressly set forth in the claims.

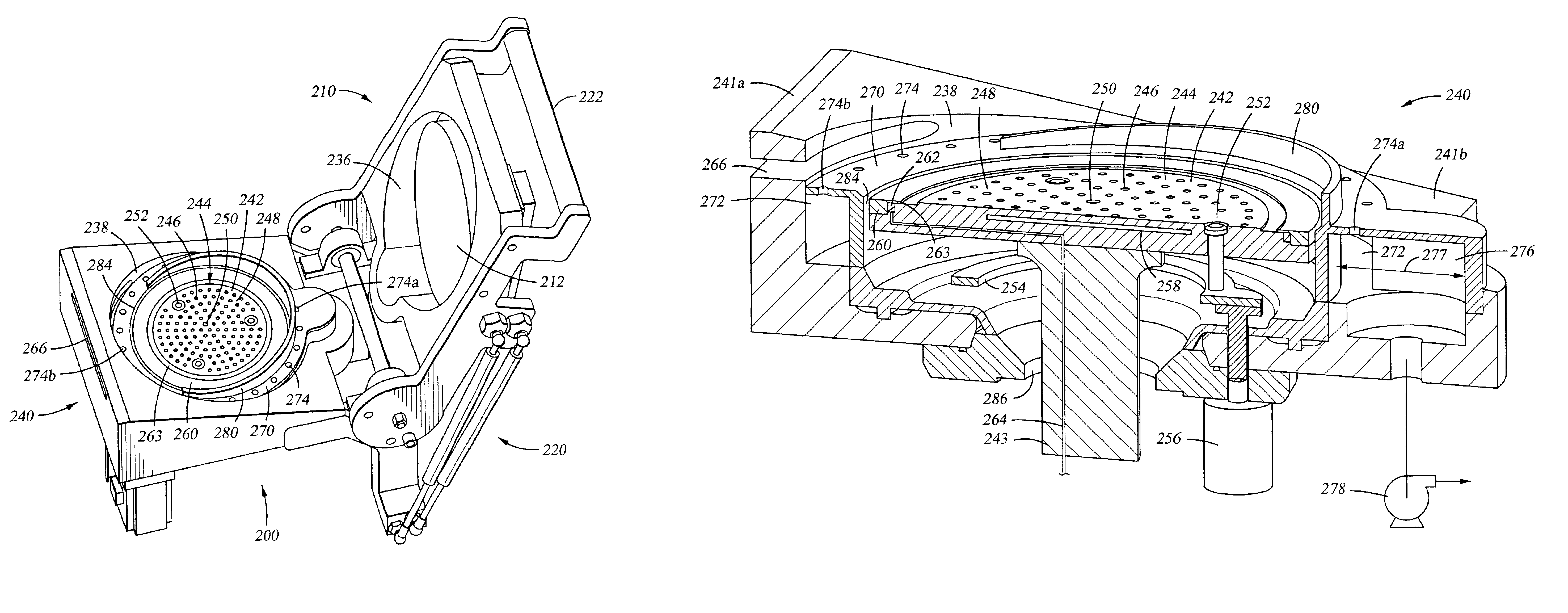

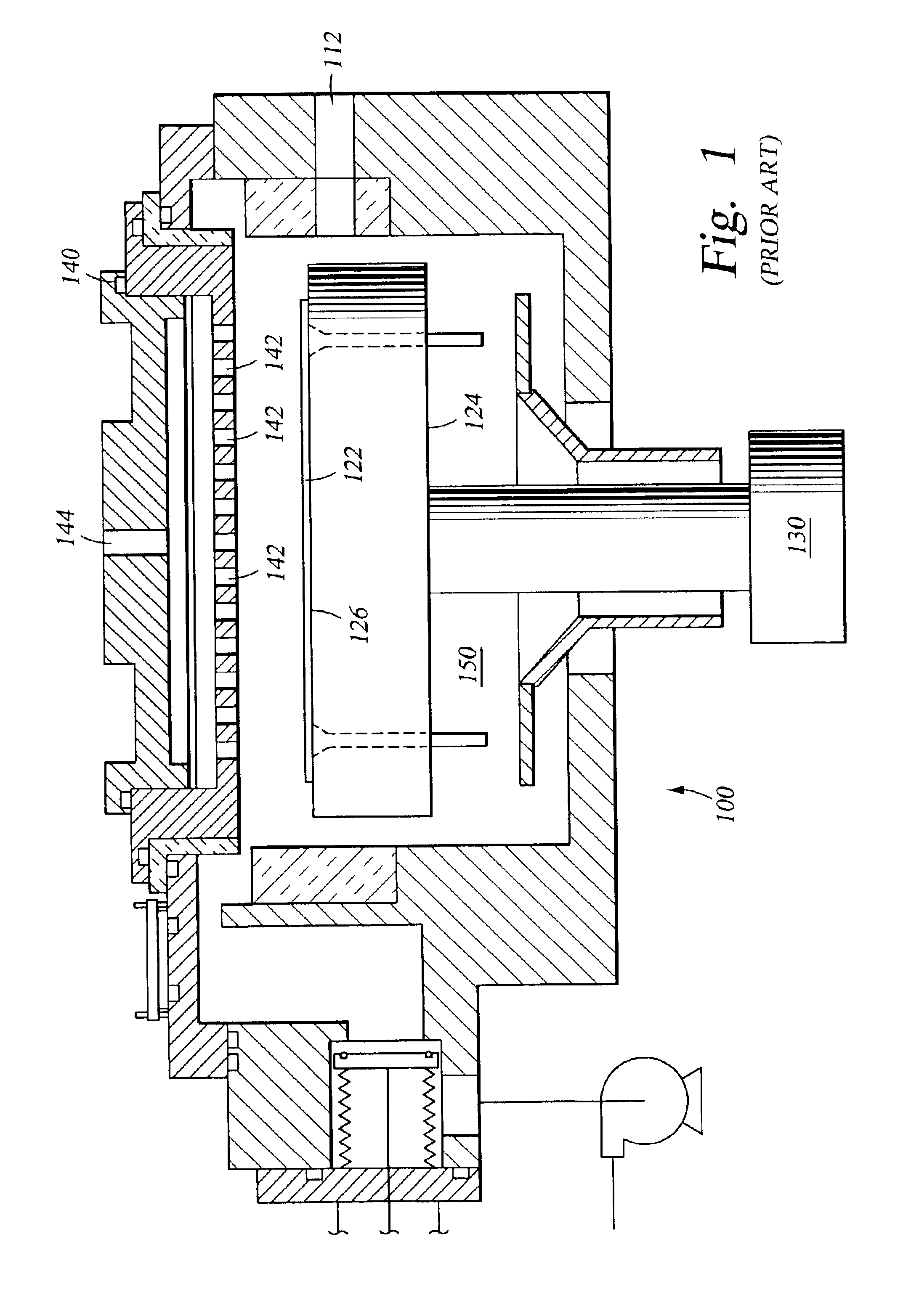

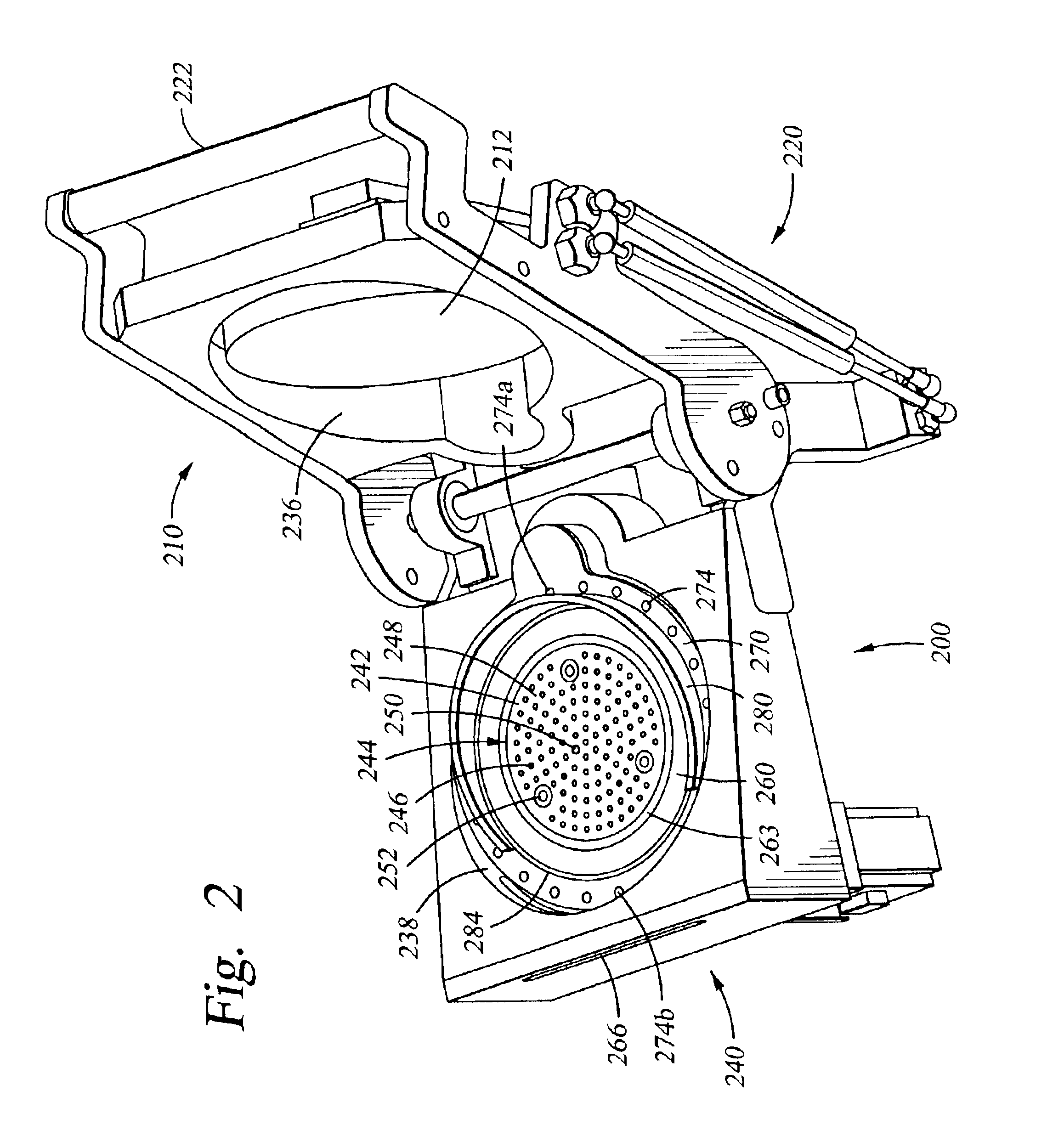

Simulations were conducted of the flow of gases in regards to chambers, such as a chamber described in reference to FIG. 2 and FIG. 4, having gas-flow diffusers of different heights. An uniform top flow of gases was provided to the substrate. Each chamber included a pumping ring having 24 apertures and a gas-flow diffuser extending between about 60% and about 70% around the perimeter of the substrate receiving surface 244. In Example 1, the gas-flow diffuser had a tapered height with a maximum height of about 0.8 inches. In Example 2, the gas-flow diffuser had a tapered height with a maximum height of about 0.7 inches. The simulations estimated the velocity of gases 0.1 inch above a substrate positioned on a substrate support of the chambers. Th

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap