Method of manufacturing electro-optical device, electro-optical device, transferred chip, transfer origin substrate

a manufacturing method and technology of electrooptical devices, applied in the field of display devices, can solve the problems that the manufacturing cost may depend on the area, and achieve the effects of reducing the cost and production yield, reducing the cost of electronic devices, and constructing with low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043]A structure and a manufacturing method of a display device to be driven with thin film transistors according to an exemplary embodiment of the present invention is described in detail below. In this exemplary embodiment, an organic EL display device is described as an example of the display device to be driven with thin film transistors.

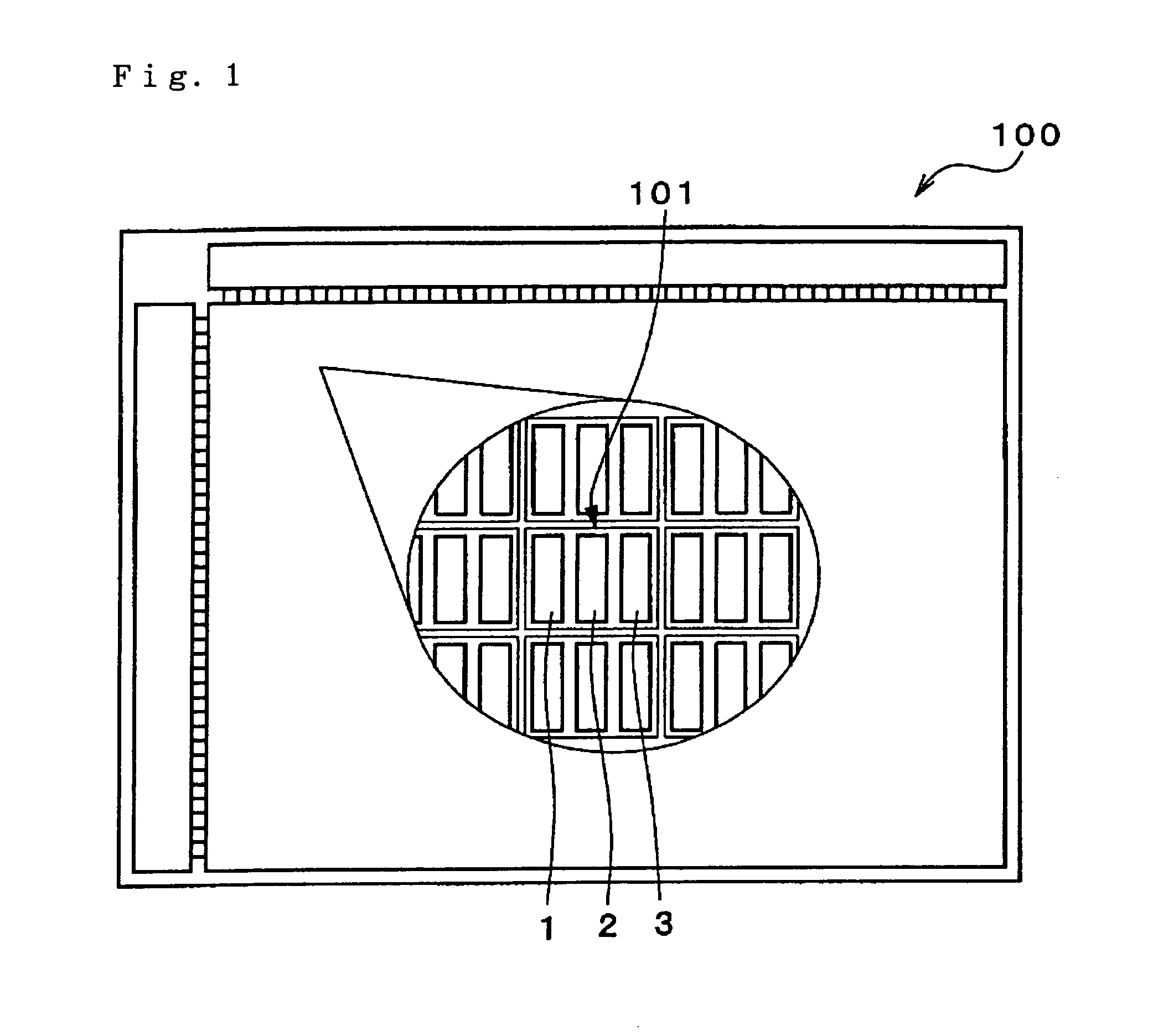

[0044]FIG. 1 is a schematic illustrating a configuration of the organic EL display device according to this exemplary embodiment. In the organic EL display device 100 shown in FIG. 1, a plurality of pixels (basic pixels) 101, each of which includes three-color pixels 1, 2, 3, is arranged in a matrix shape.

[0045]Among the color pixels, for example, the color pixel 1 corresponds to a red color, the color pixel 2 corresponds to a green color, and the color pixel 3 corresponds to a blue color. The respective pixels 101 are driven by chips having a drive circuit built in, the drive circuit including a plurality of thin film transistors (TFTs).

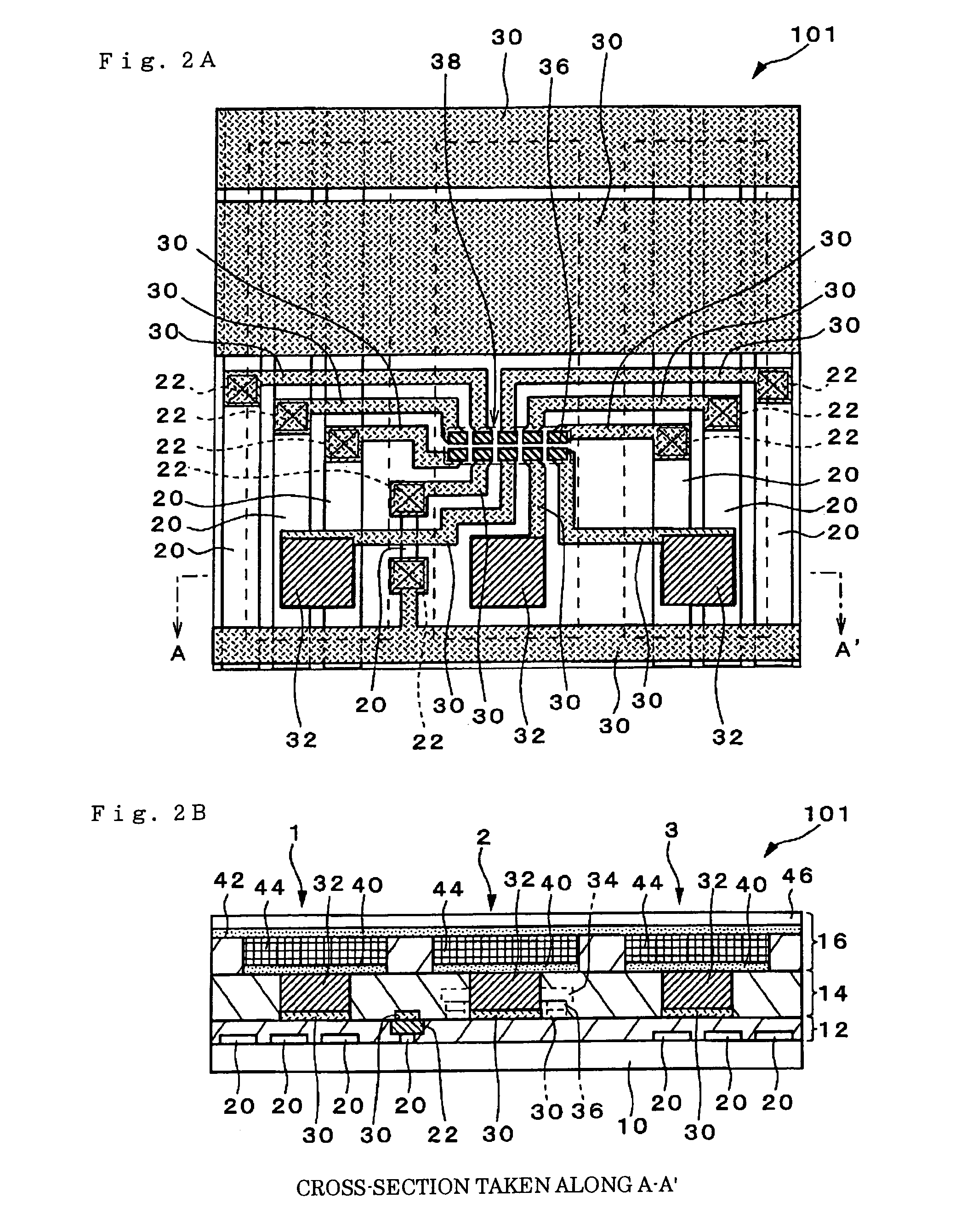

[0046]FIG

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap