Automatic mold material taking device

A technology of automatic reclaiming and moulding, applied in stripping devices, forming tools, manufacturing tools, etc., can solve problems such as leakage of screws, cable damage, affecting the service life of cables, etc., to reduce interruption or damage, use Long life and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

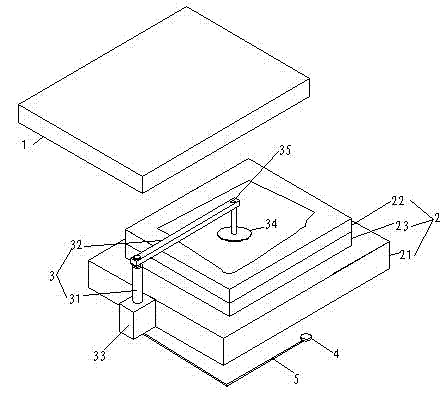

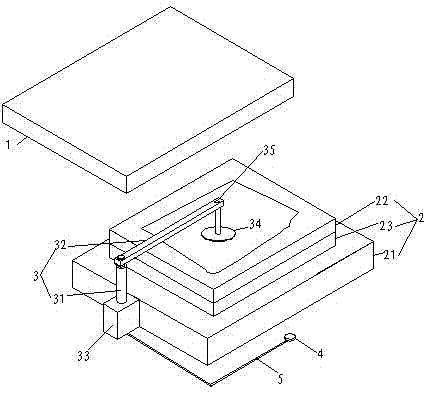

[0015] see figure 1 , the embodiment of the present invention includes: an automatic mold retrieving device, including an upper mold 1, a lower mold 2 and a rotating arm 3, the rotating arm 3 includes a bracket 31 and a beam 32, a rotating motor 33 is set at the bottom of the bracket 31, and a rotating motor 33 is installed on the beam One end of 22 is provided with a suction cup 34, the other end of the beam 32 is connected to the upper part of the bracket 31, the rotating arm 3 is placed between the upper mold 1 and the lower mold 2, and the front end of the lower mold 2 is provided with a start switch 4, which is connected by a cable 5 Rotate the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap