Insulating rod

An insulating rod and rod body technology, which is applied to cable installation devices, electrical components, circuits, etc., can solve the problems of increasing the labor intensity of operators, time-consuming insulating rods, and delay in switching operation time, so as to save switching operation. Time and structure operation is simple and convenient, and the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

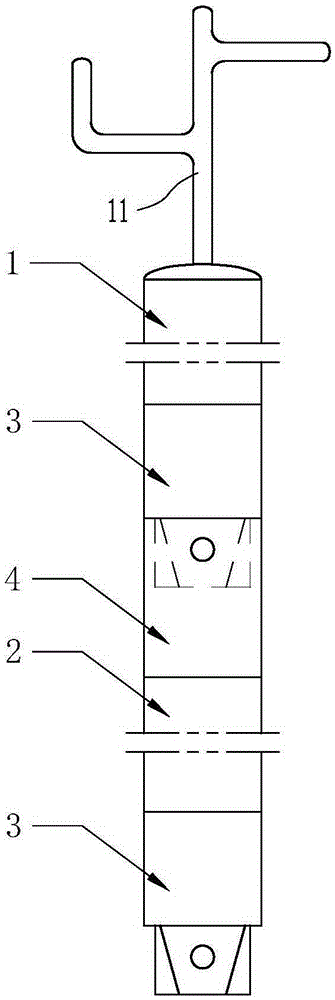

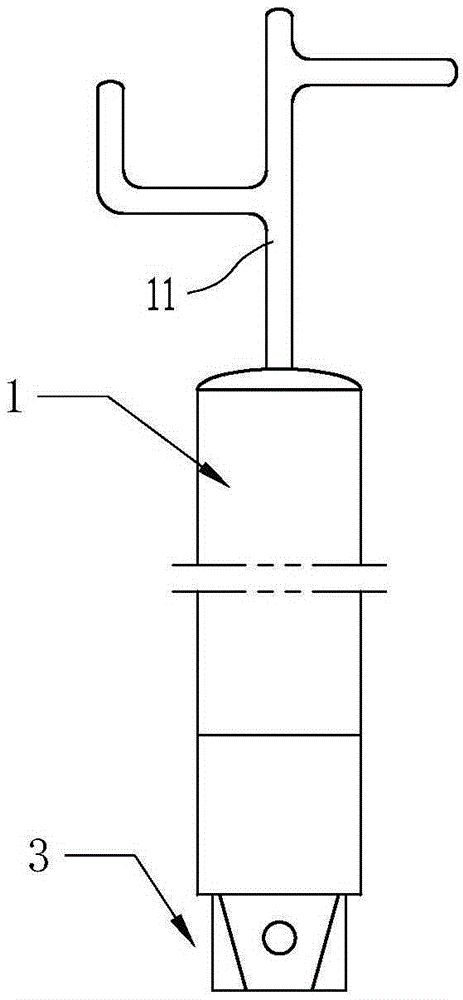

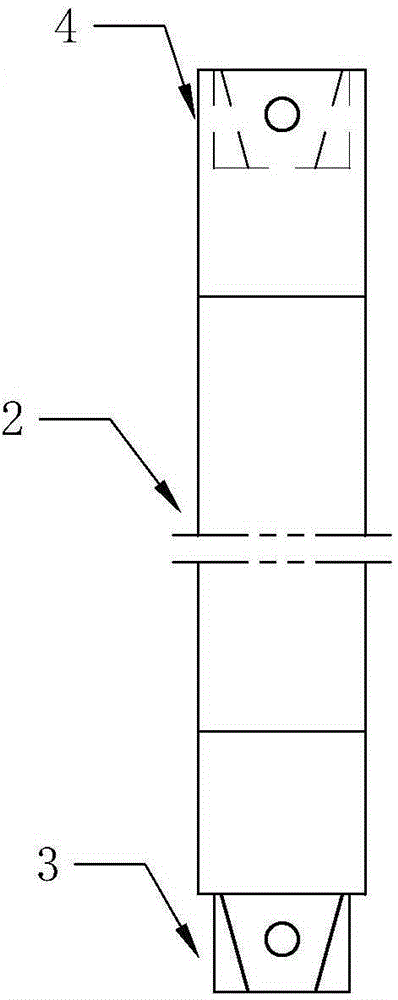

[0022] like figure 1 , figure 2 and image 3 As shown together, the insulating rod includes a first rod body 1 and a second rod body 2 connected together, one end of the first rod body 1 is provided with a working head 11 , and the other end is fixed with a connecting head 3 . One end of the second rod body 2 is fixedly provided with a connecting head 3 , and the other end is fixedly provided with a connecting seat 4 . The connecting head 3 of the first rod body 1 is fixedly connected with the connecting seat 4 of the second rod body 2 , and the connecting head 3 is plugged into the connecting sea

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap