Stamping die capable of keeping pressing leftover material parts of plates

A technology for stamping dies and scraps, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as personal injury, scrap punching, splashing, etc., to achieve long service life, avoid scrap rebound, and good versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] It should be noted that, in the case of no conflict, the embodiments and the features in the embodiments of the present invention can be combined with each other.

[0017] Specific embodiments of the present invention will be described in detail below.

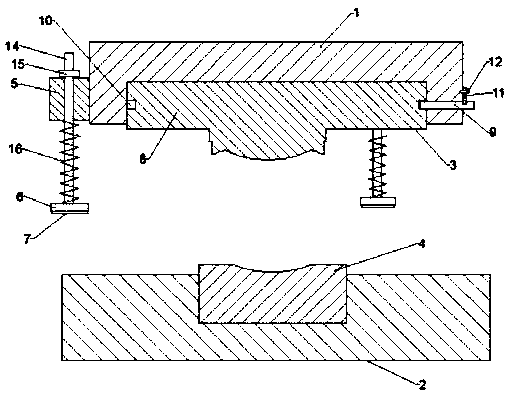

[0018] A stamping die capable of keeping part of the plate scraps pressed, such as Figures 1 to 2 As shown, it includes an upper die base 1 and a lower die base 2, the lower end of the upper die base is provided with a punch 3, the upper end of the lower die base is provided with a die 4, and several punches are evenly arranged on the upper die base with the punch as the center. Compression device; said compression device comprises a base 5, several compression mechanisms between the base 6 and the base and the pressure plate below the base; the lower end of the pressure plate is provided with a pressure pad 7, usually, the pressure pad adopts Nylon pad or rubber pad; the lower end of the upper die base is provided with

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap