Backplane quality control method

A backplane and control technology, which is applied in the field of production process and backplane quality control, can solve the problems of residual drying impurities in drilling holes, outflow of processing fluid, and complex number of drilling holes, so as to prevent bad loss, ensure production quality, The effect of accurate information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

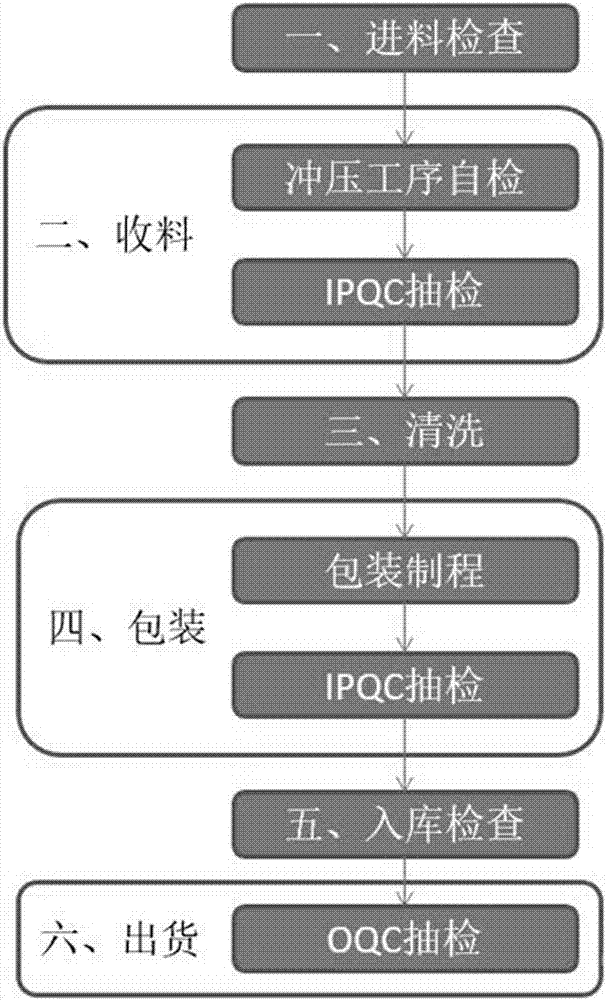

[0072] like figure 1 As shown, a backplane quality control method comprises the following steps,

[0073] Step 1, incoming material inspection;

[0074] Step 2, receiving materials;

[0075] In said step 2, receiving materials is divided into two links, S1, stamping process self-inspection; S2, IPQC random inspection;

[0076] Step three, cleaning;

[0077] Step four, packaging;

[0078] In the step 4, the packaging is divided into two links, Y1, packaging process; Y2, IPQC random inspection;

[0079] Step five, storage inspection;

[0080] Step six, shipping.

[0081] The operating conditions of the tank cleaning machine are the pre-order work of the backboard packaging, so it is particularly important. It should be pointed out that dry

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap