Automotive chassis support positioning mechanism and offline detection platform

A support positioning and automobile chassis technology, which is applied to vehicle parts, auxiliary welding equipment, welding equipment, etc., can solve the problems of large storage space, few compatible models, and poor retrofitability, etc., to achieve fast switching speed, ensure accuracy and Stability, the effect of occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0037] The support and positioning mechanism of the automobile chassis in the preferred embodiment of the present invention includes a base, a common positioning unit, a fixing unit, a switching unit and a switching handle.

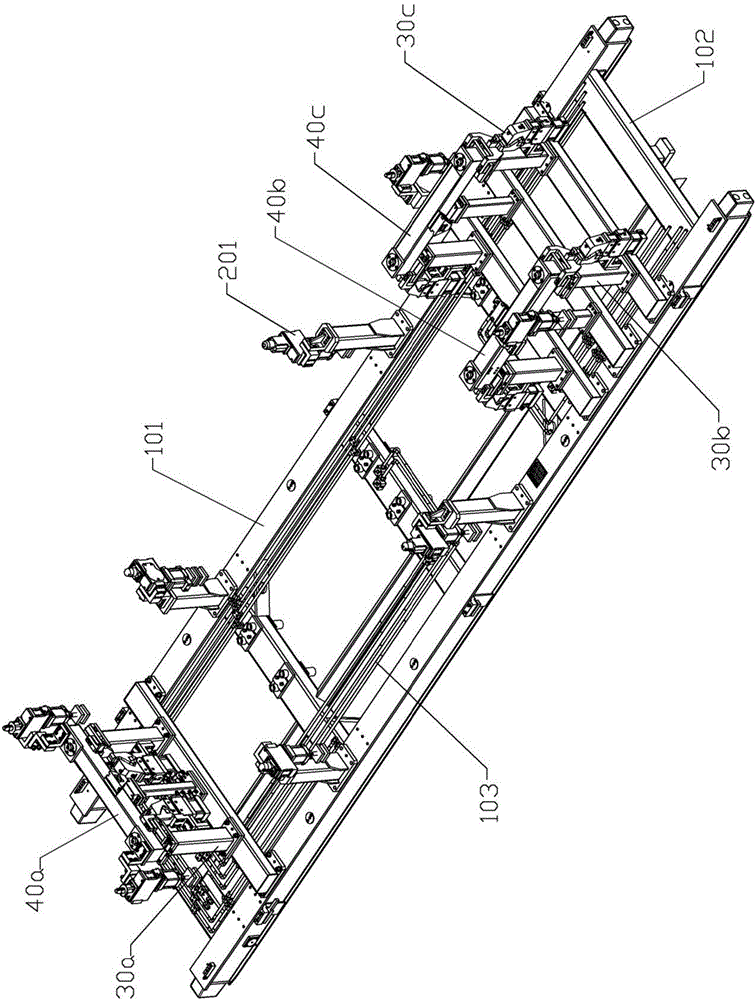

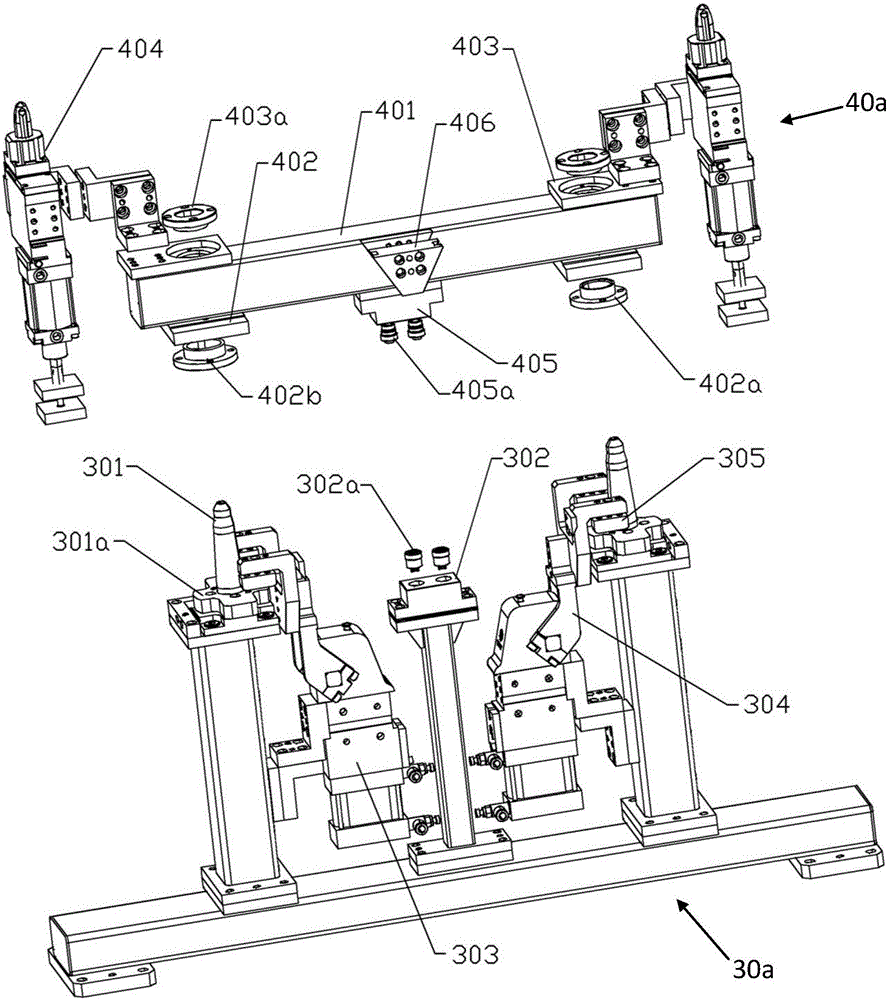

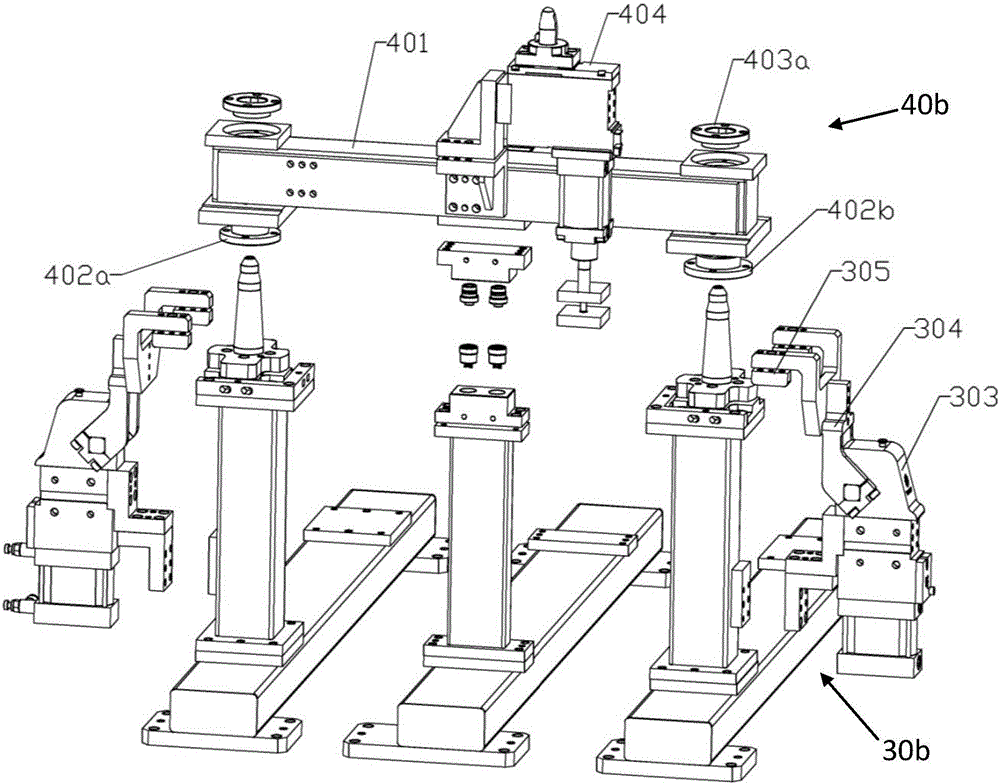

[0038] figure 1 Shown is the supporting and positioning mechanism of the installed automobile chassis, wherein the base is composed of two long steel bars 101 and five short steel bars 102, and a ventilation pipeline 103 is laid on the base, and the ventilation pipeline 103 includes a first ventilation pipeline and the second ventilation pipeline, the first ventilation pipeline and the second ventilation pipeline are respectively provided with a plurality of ventilation openings.

[0039] The common positioning unit includes four second pin-type clamping cylinders 201, and the second pin-type clamping cylinders 201 are symmetric

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap