Method for forming negative tone pattern, method for manufacturing electronic device, and active-light-sensitive or radiation-sensitive resin composition

a technology of negative tone pattern and resin composition, which is applied in the direction of photosensitive material processing, photomechanical equipment, instruments, etc., can solve the problems of uneven pattern formation, and deterioration of pattern accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0558]Hereinafter, the present invention will be described in more detail with reference to Examples, but the present invention is not limited thereto.

Synthesis Example: Synthesis of Polymer (1)

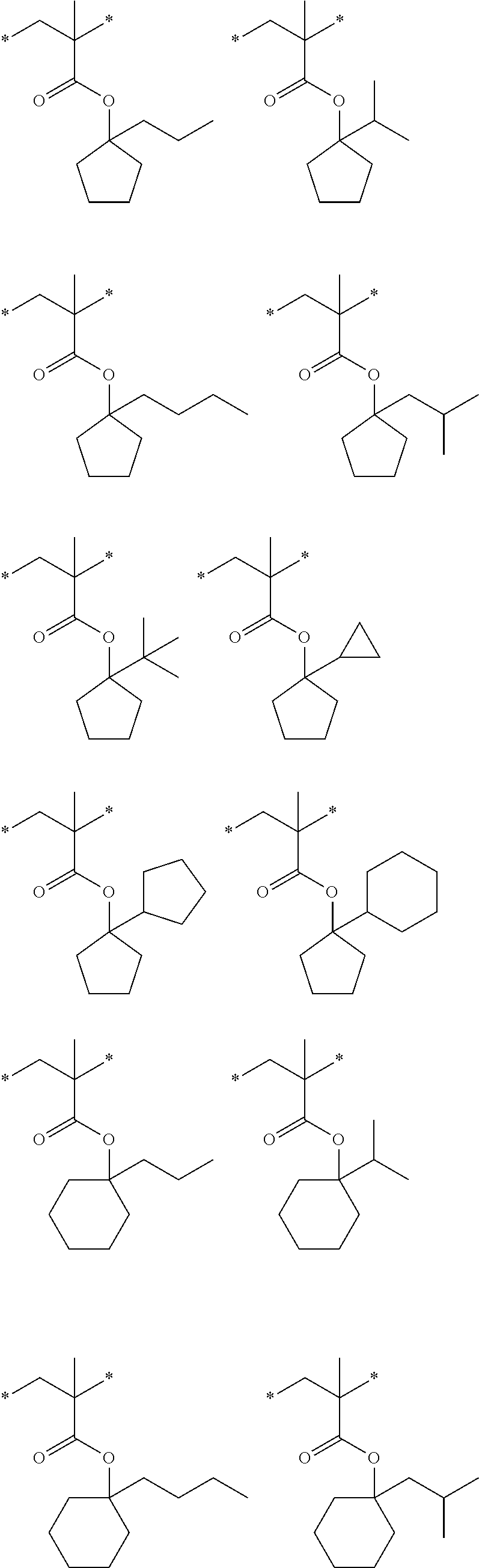

[0559]42.86 parts by mass of cyclohexanone was heated at 80° C. under a nitrogen stream. While stirring this liquid, a mixed solution of 13.33 parts by mass of a monomer represented by the following structural formula M-1, 27.48 parts by mass of a monomer represented by the following structural formula M-2, 79.59 parts by mass of cyclohexanone, and 1.84 parts by mass of dimethyl 2,2′-azobisisobutyrate [V-601, manufactured by Wako Pure Chemical Industries, Ltd.] was added dropwise to the liquid for 6 hours. After completion of the dropwise addition, the mixture was further stirred at 80° C. for 2 hours. After being left to be cooled, the reaction liquid was reprecipitated with a large amount of methanol / water (mass ratio of 90:10) and filtered, and the obtained solid was dried in vacuo to obtai

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mole | aaaaa | aaaaa |

| Percent by mole | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap