Self-rotating type bottle body spraying device

A technology of spraying device and bottle body, which is applied in spraying device, device for coating liquid on the surface, coating and other directions, can solve the problems such as the inability to carry out bottling and rotation spraying, automatic spraying, and complicated transmission structure for small bottle bodies. , to achieve the effect of stable and uniform surface quality, convenient loading and unloading, and high spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

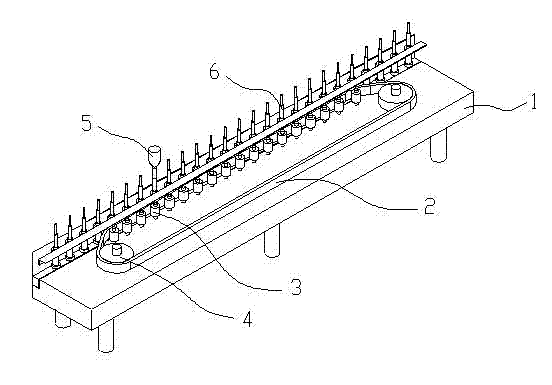

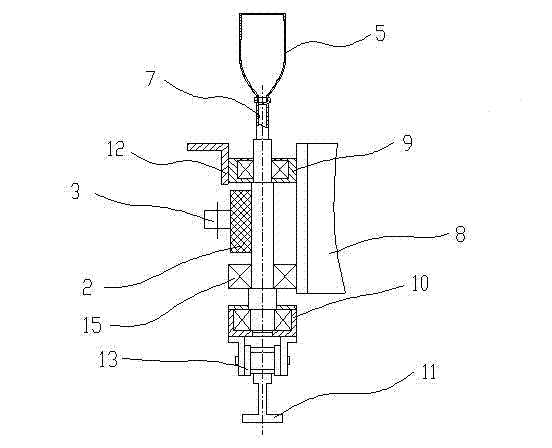

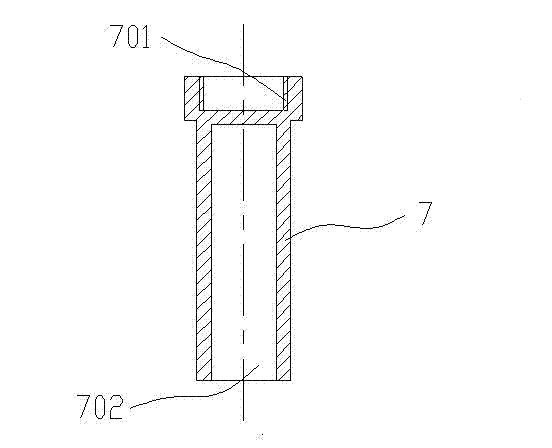

[0022] A kind of self-rotating bottle body spraying device of present embodiment, see figure 1 , a base frame 1 is set in the spraying operation area, and the traction conveyor chain 13 running horizontally passes through the base frame 1. The traction conveyor chain 13 is supported by the driving device, and the friction drive belt 2 is installed on the base frame 1. A part of the base frame 1 A guide groove rail 12 is established on the side, and a vertical shaft 6 is vertically adorned on every two chains on the traction conveyor chain 13, and roller 9 is housed on the vertical shaft 6, as figure 2 As shown, the roller 9 runs along the guide groove rail 12, the guide groove rail 12 is composed of a guide rail seat 8 and an angle steel, the lower end of the vertical shaft 6 is connected to the traction

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap