Solar cell assembly gantry storage stacking machine

A solar cell and gantry-type technology, which is applied in the stacking, transportation and packaging of objects, can solve problems affecting the normal production of solar cell components, vibration of solar cell components, large deformation of the storage layer, etc., and achieve geometric size reduction and rigidity The effect of increasing and shortening the length of the post

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

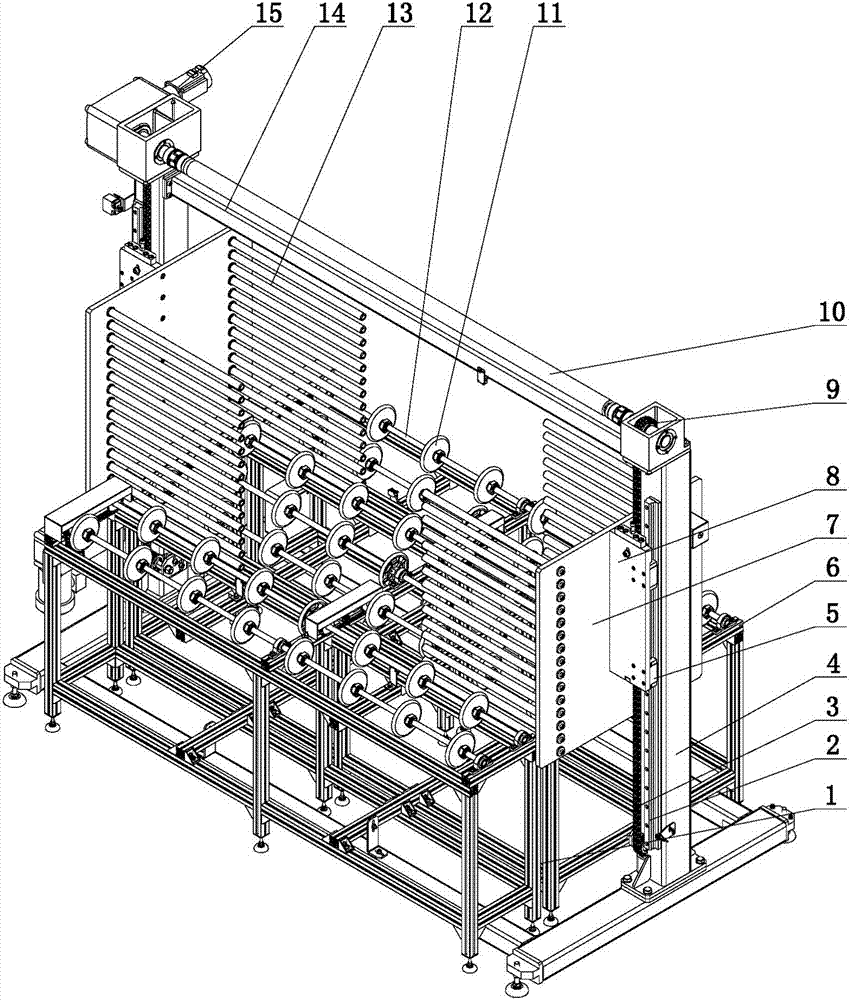

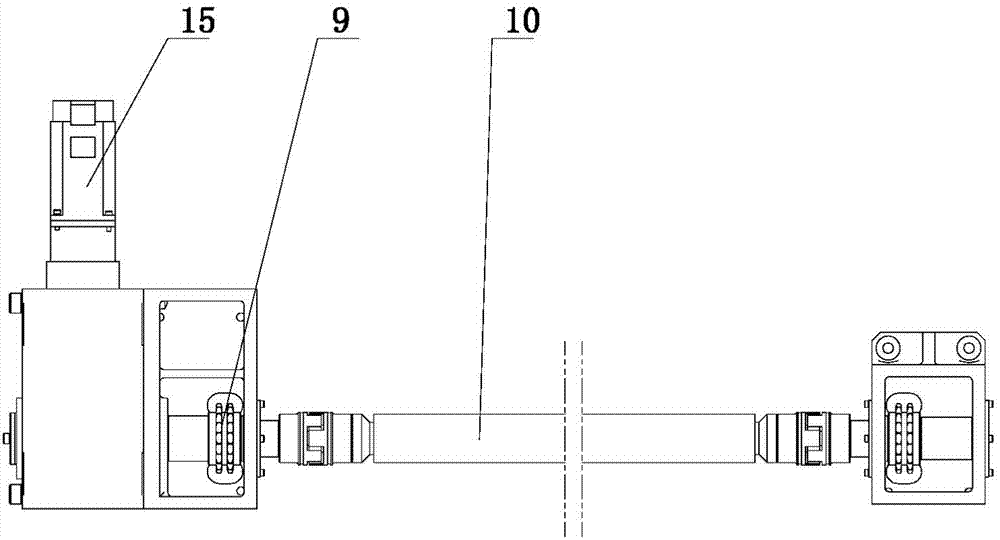

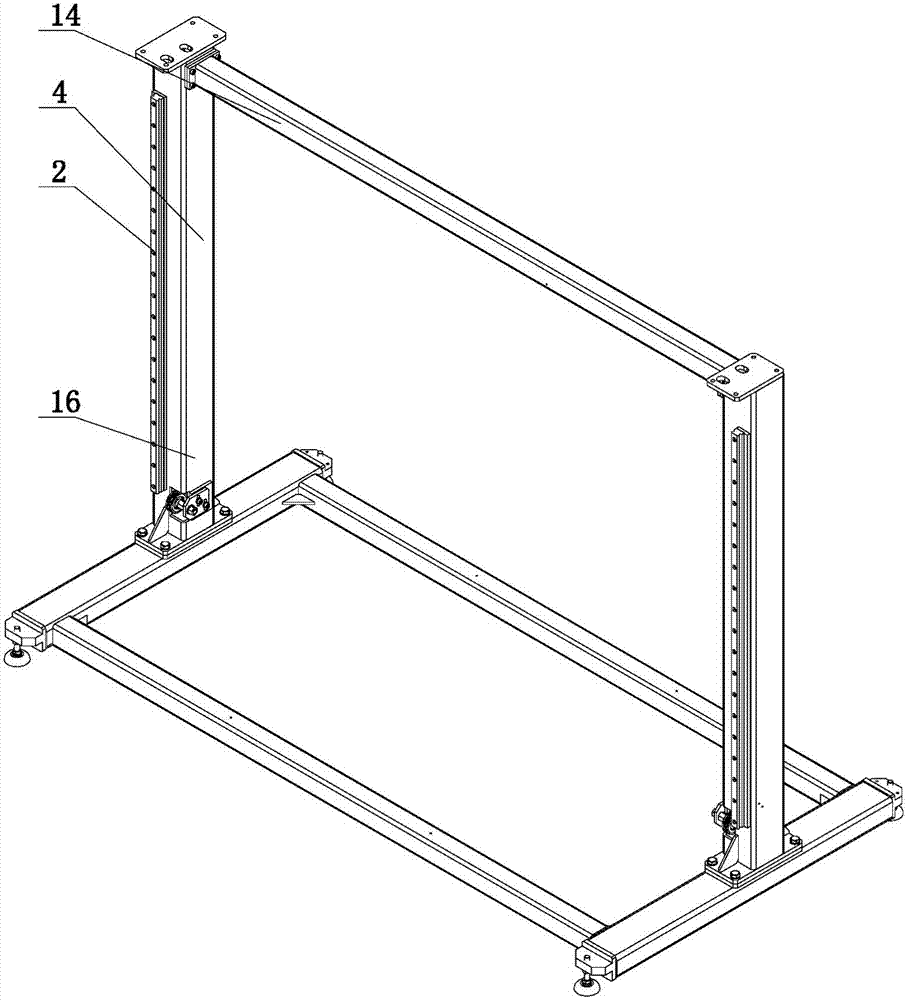

[0013] The present invention includes a transmission base 1, the transmission base 1 described in its structural points includes a frame 6, on which two or more transmission shafts 12 are arranged, and transmission wheels 11 are arranged on the transmission shafts 12; There is a gantry 16 composed of a crossbeam 14 and a column 4, and vertical synchronous chains 3 are arranged at both ends of the crossbeam 14 of the gantry 16, and the two synchronous chains 3 are connected with the lifting motor 15; brackets are arranged on the two synchronous chains 3 7. The opposite side of the two brackets 7 is provided with a support column 13 corresponding to the gap of the transmission shaft 12 .

[0014] The transmission shafts 12 are connected through a transmission chain. It is ensured that the rotating speed of the transmission shaft 12 is the same, and the transmission of the solar cell assembly is stable.

[0015] The horizontal shaft 10 connected with the lifting motor 15 is arra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap