Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Stacker" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A stacker is a large machine used in bulk material handling. Its function is to pile bulk material such as limestone, ores and cereals on to a stockpile. A reclaimer can be used to recover the material.

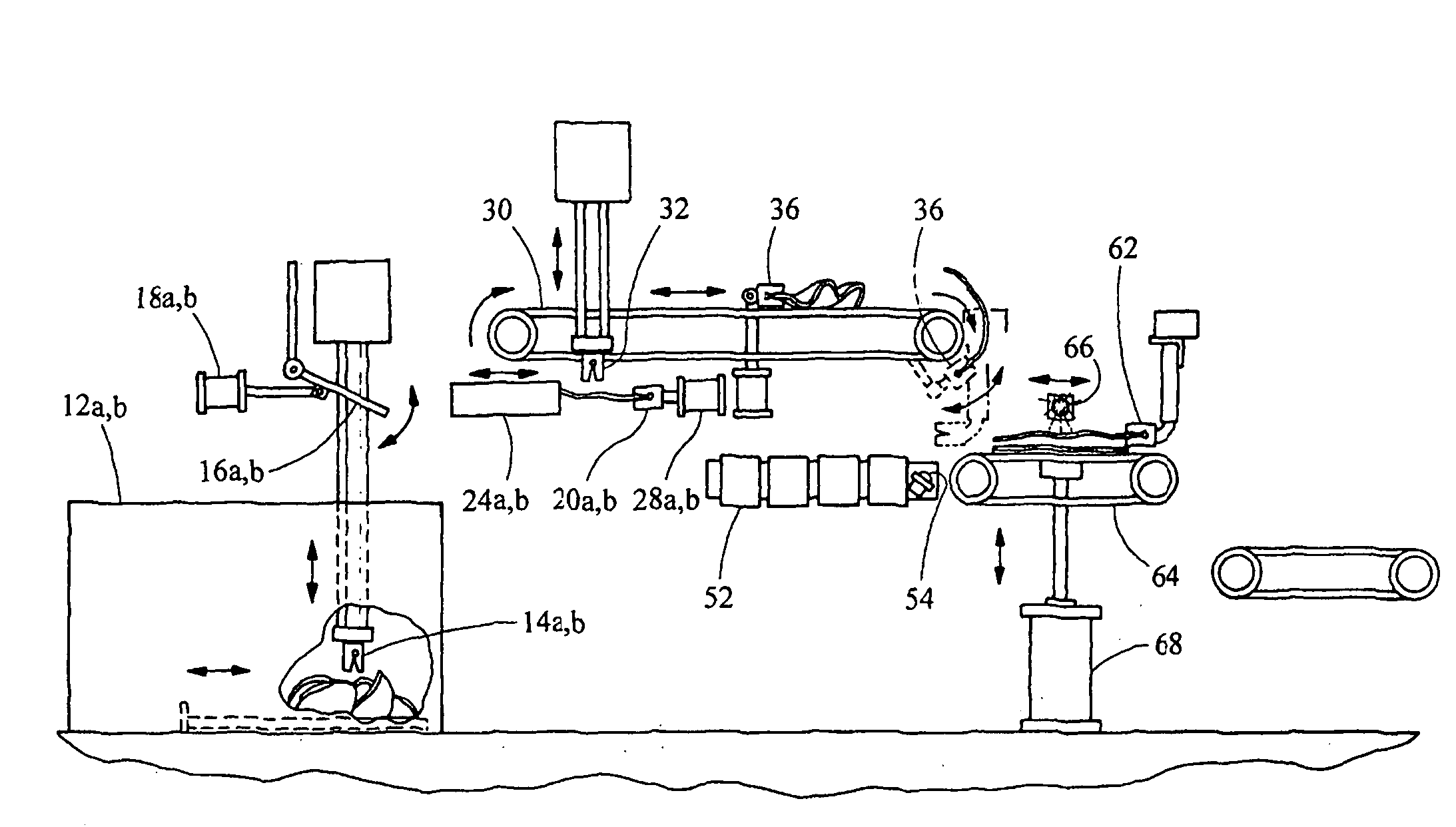

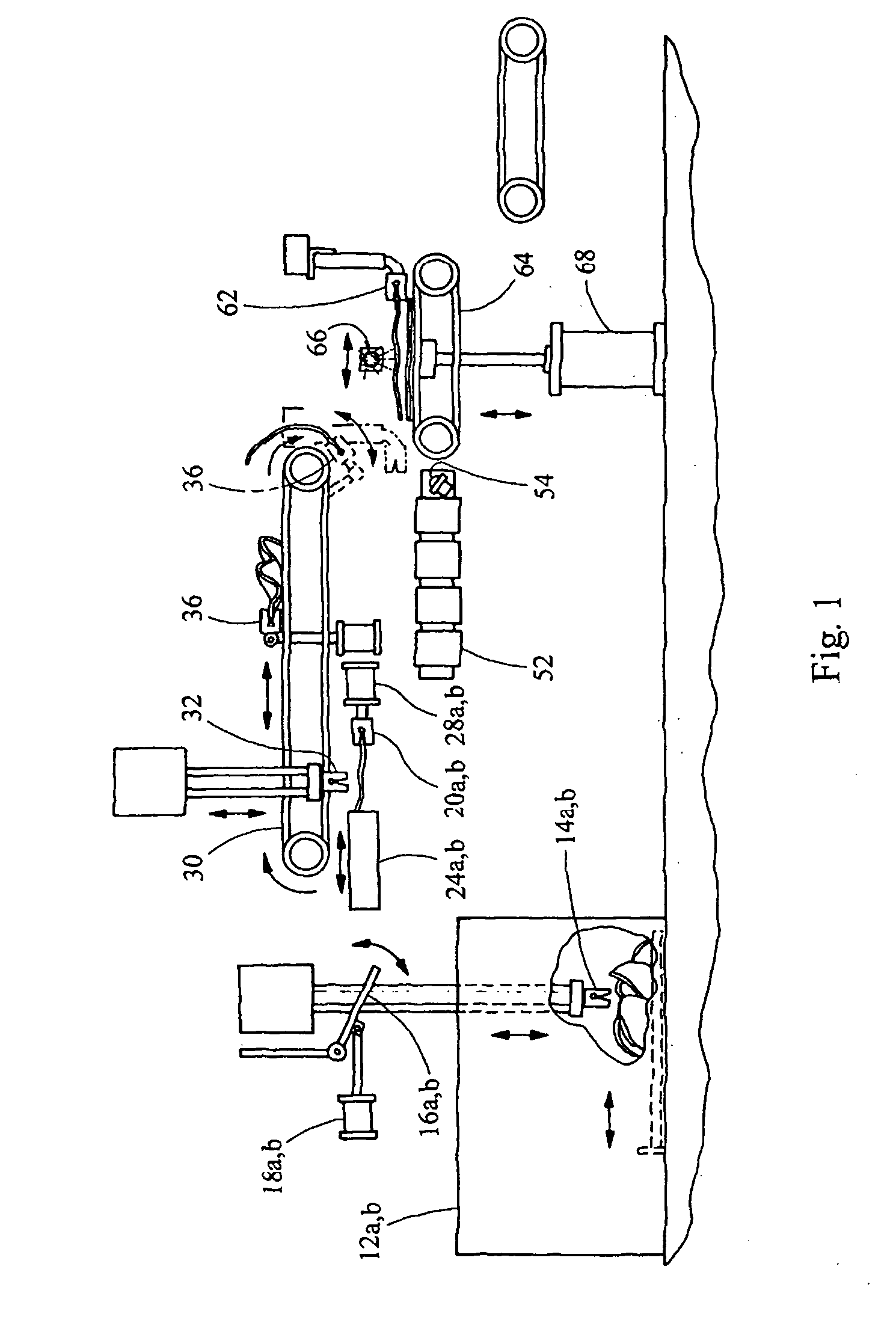

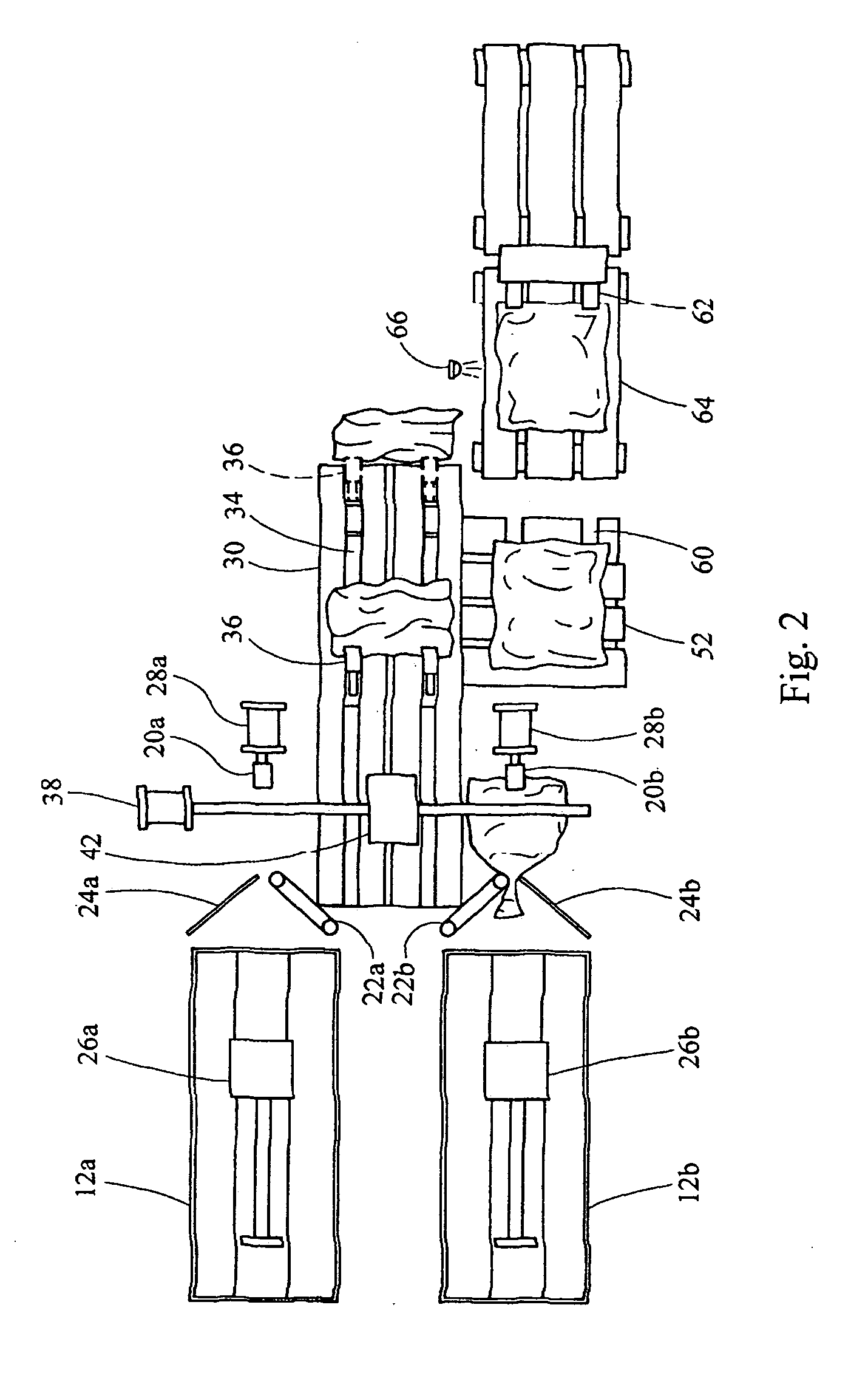

Article of laundry spreader and stacker

Owner:MCCABE STANLEY G

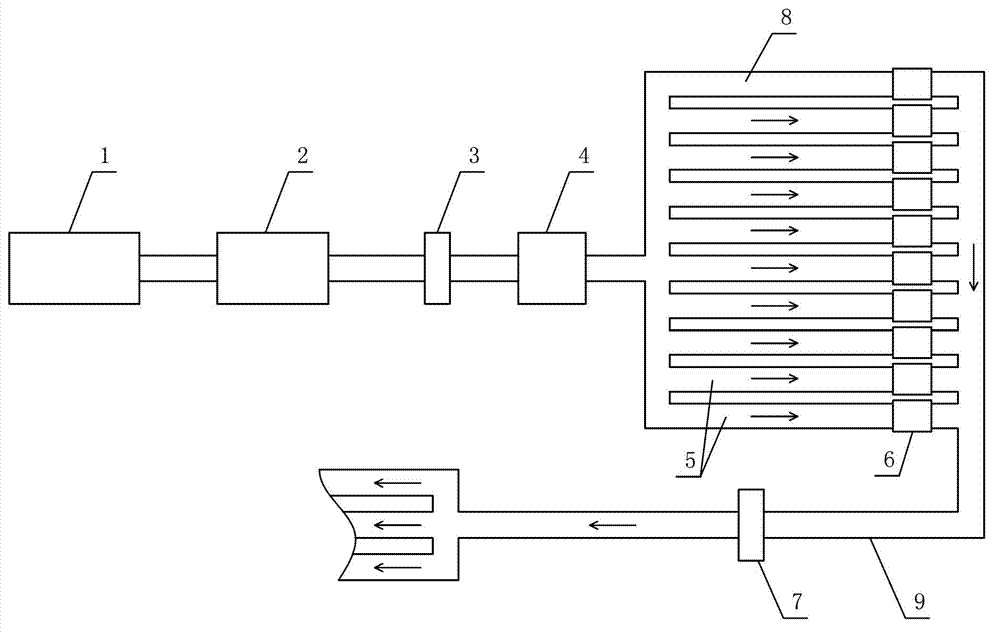

Stocking-up system and method

InactiveCN102862809ASmall footprintImprove replenishment efficiencyConveyor partsLogistics managementStack machine

Owner:浙江省烟草公司绍兴市公司

Automatic sorting device for box-shaped articles

Owner:QILU UNIV OF TECH

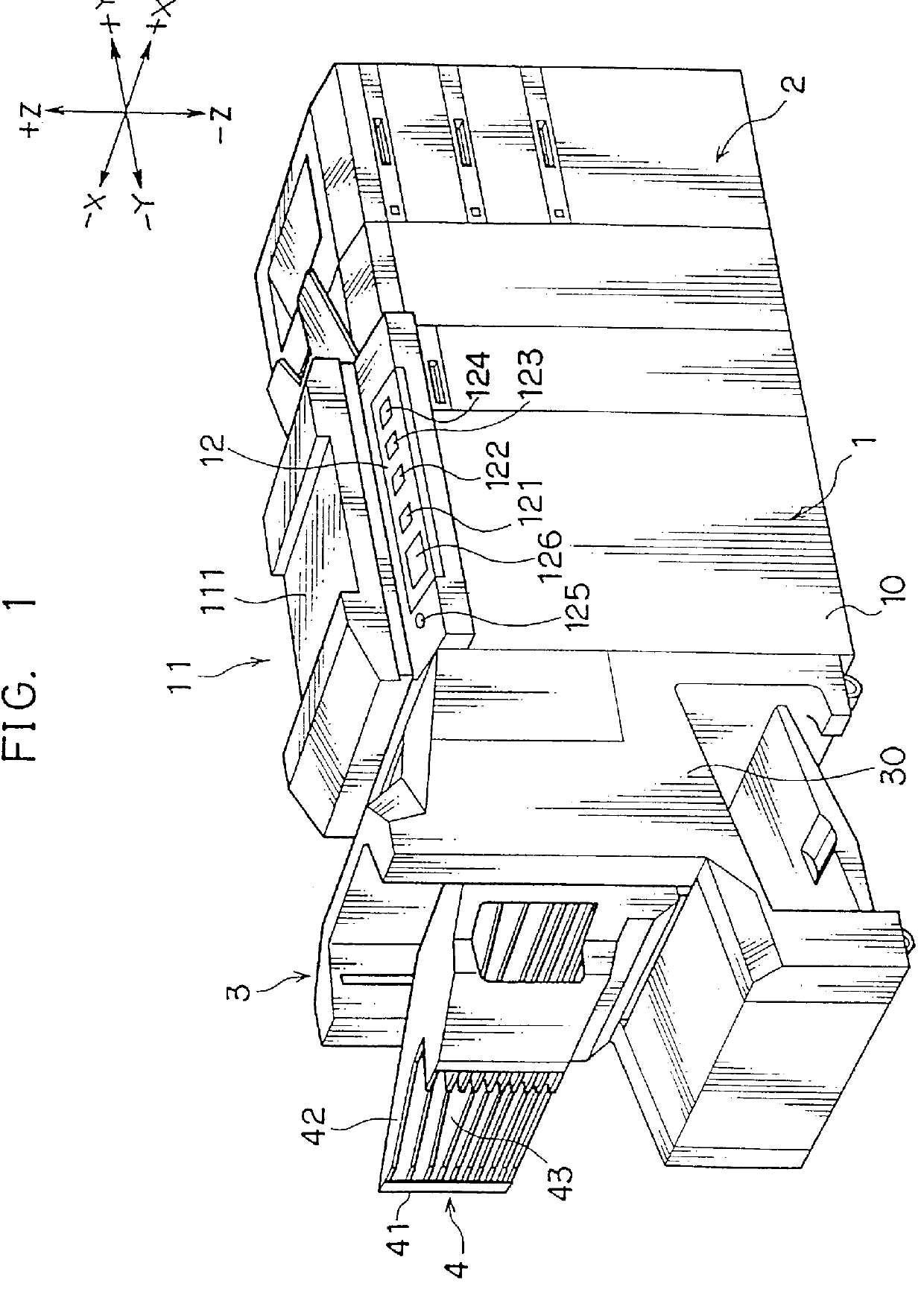

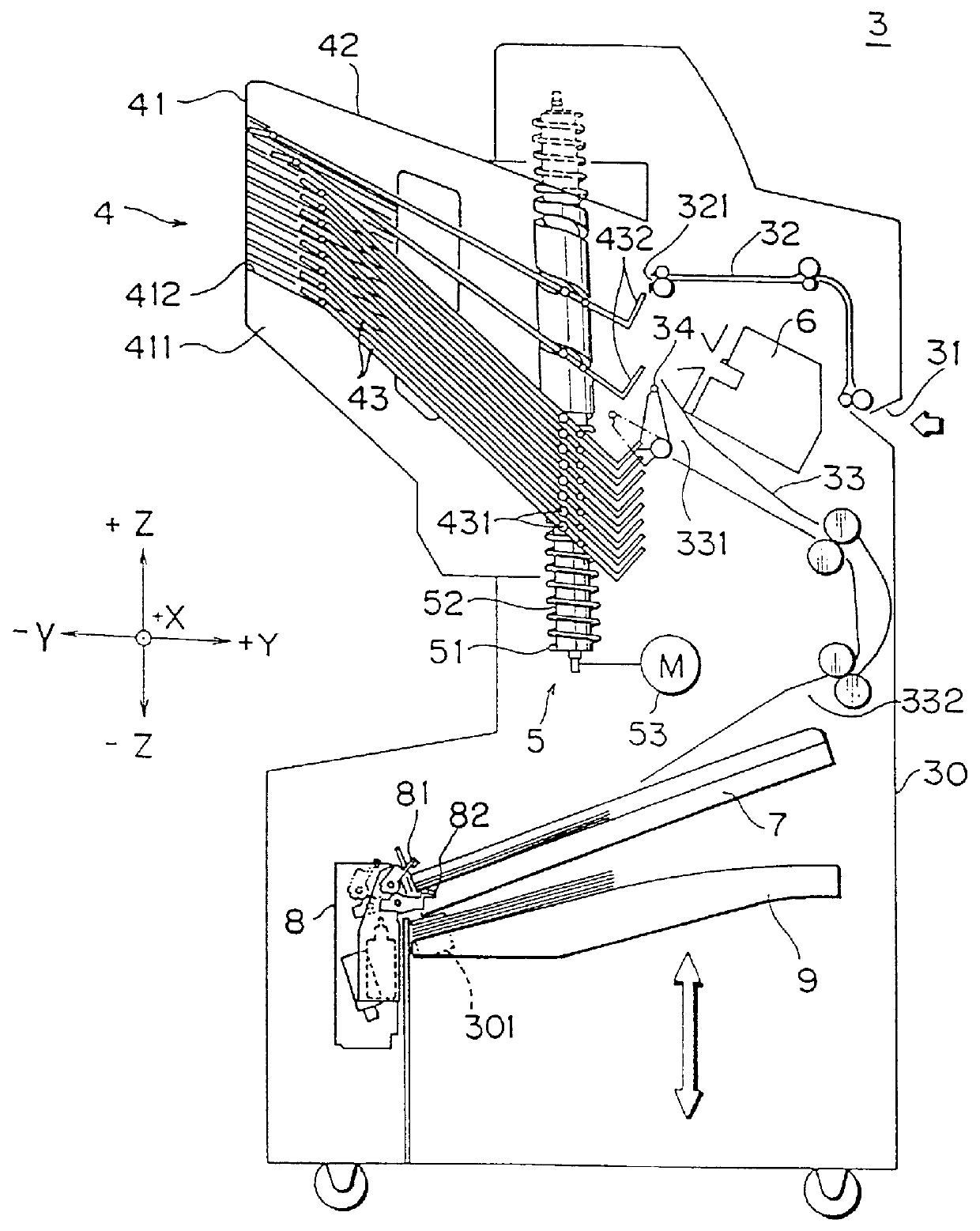

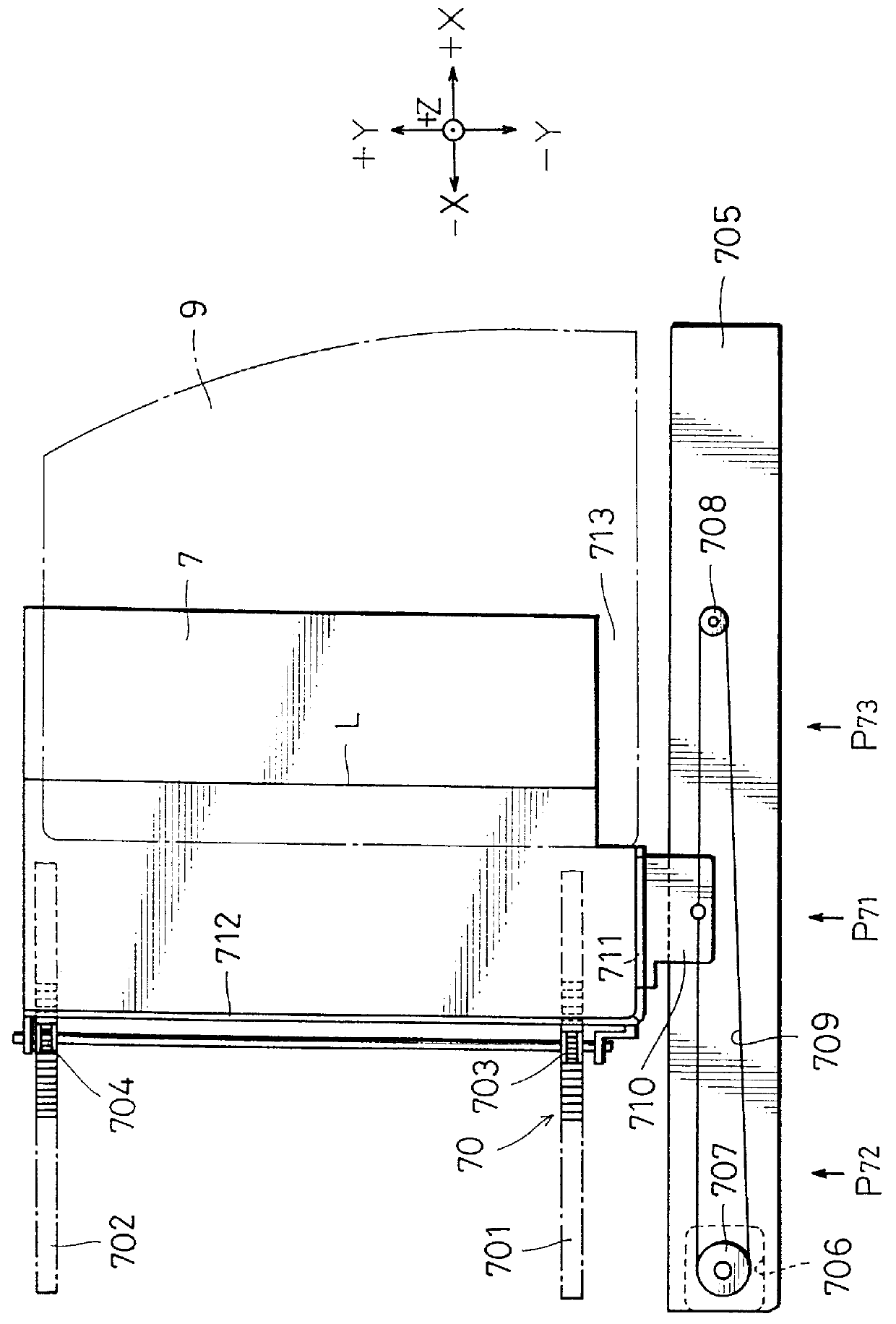

Sheet handling unit after image formation

Owner:KYOCERA DOCUMENT SOLUTIONS INC

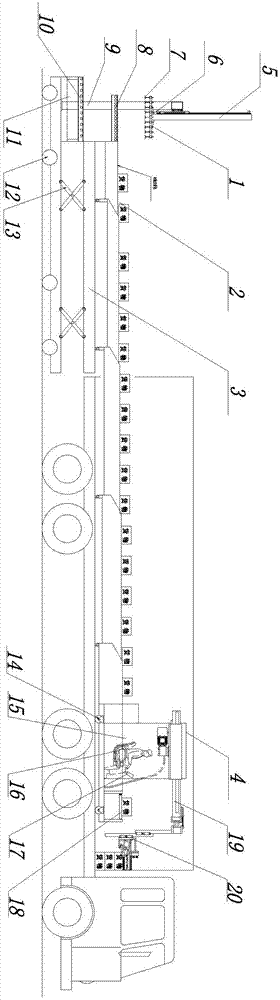

Automatic truck loading stacker crane

PendingCN106915636ASave human effortImprove palletizing efficiencyLoading/unloadingEngineeringManipulator

Owner:天津君晟科技发展有限公司

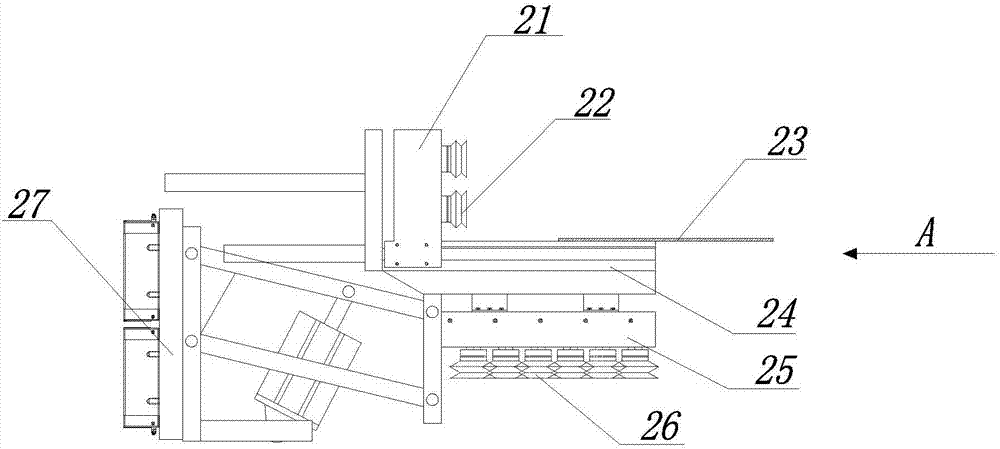

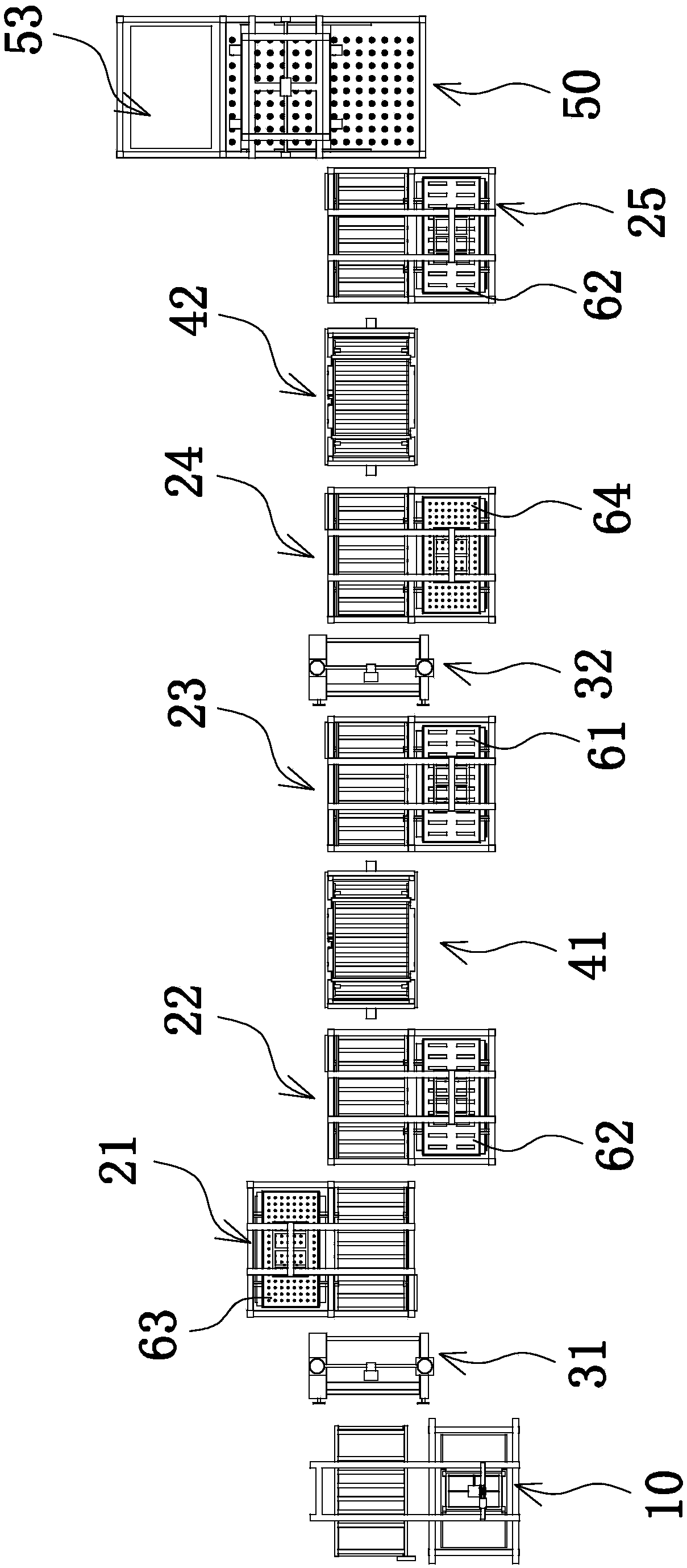

Automatic production system of rock wool sandwich board

PendingCN107891652AEasy to transportReasonable structural designLamination plant layoutLamination ancillary operationsMining engineeringSandwich board

Owner:ZHEJIANG XUANMING NEW MATERIALS

Mechanical type loosening and breaking preventing safety device for chain

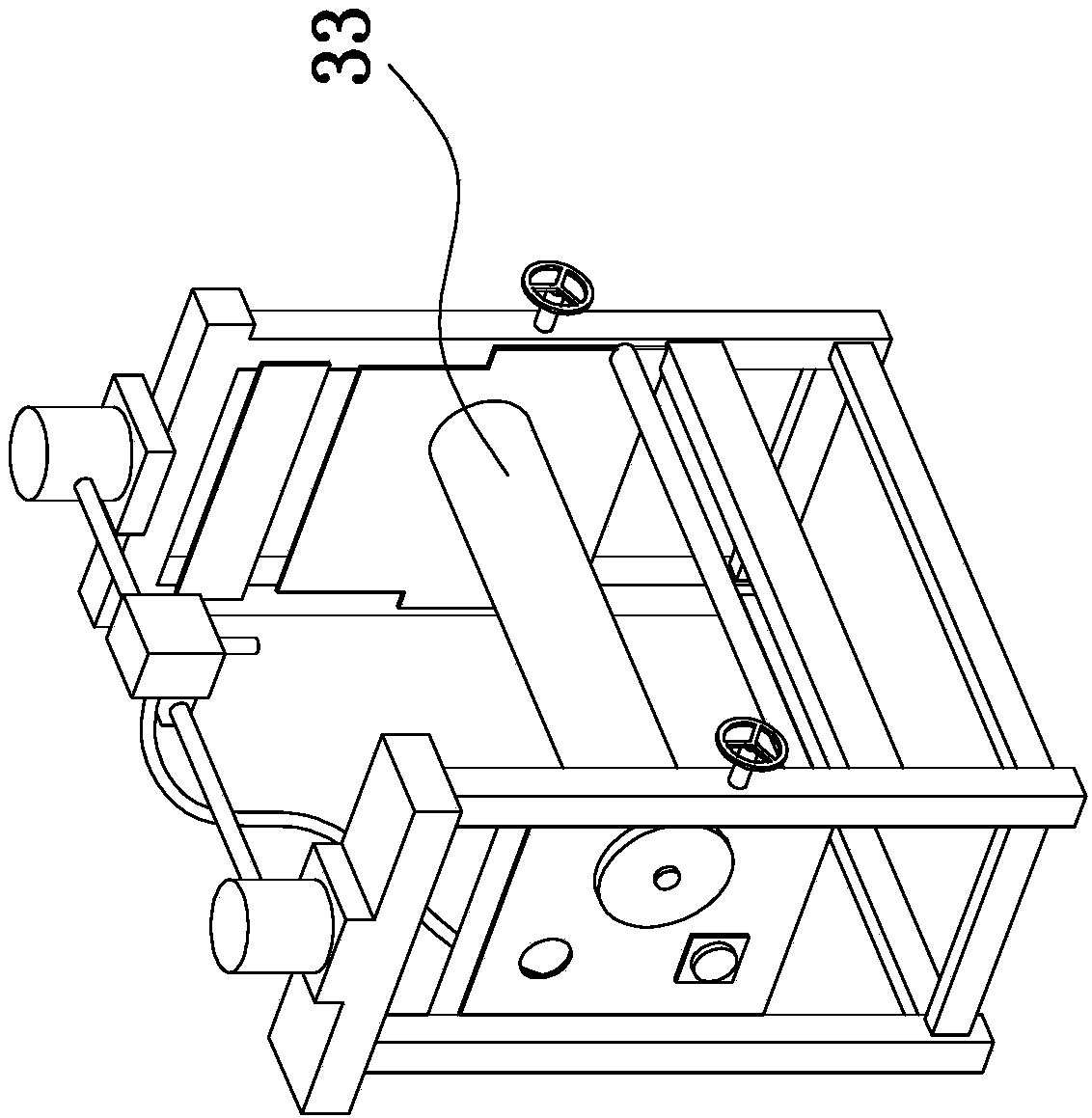

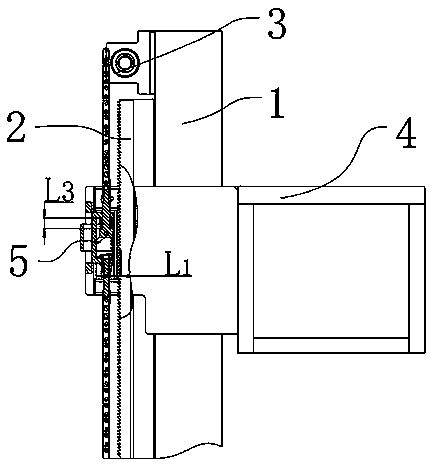

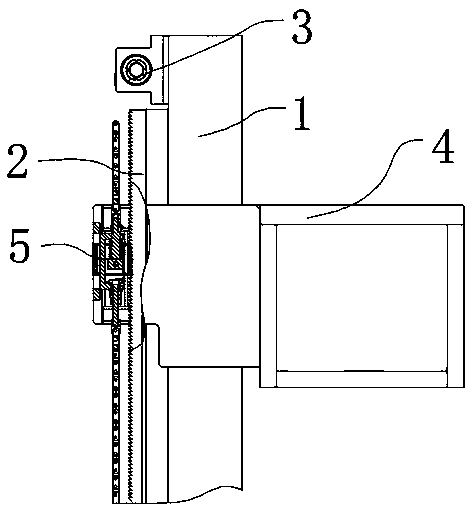

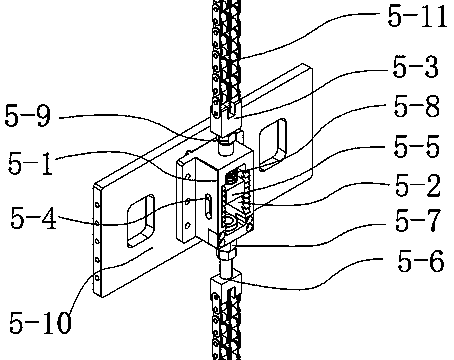

PendingCN109650293AImprove securityAvoid safety accidentsSafety devices for lifting equipmentsEngineeringSprocket

Owner:深圳市智佳能自动化有限公司

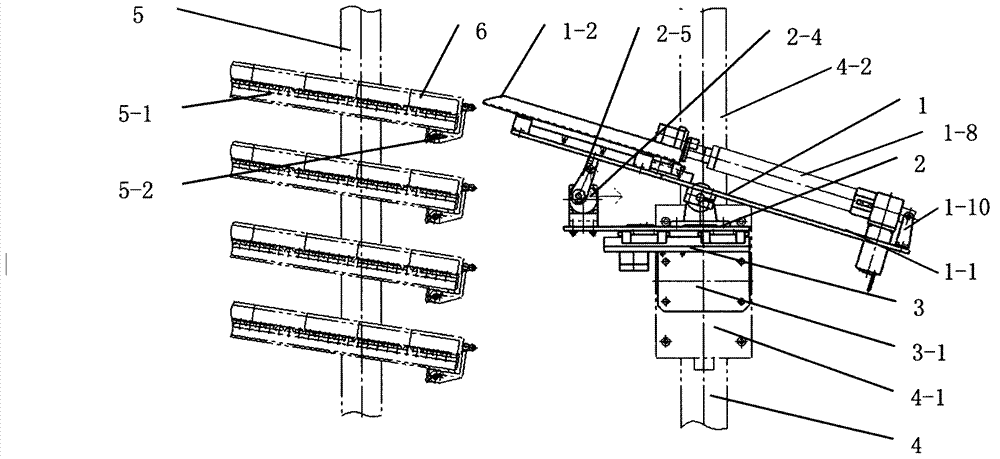

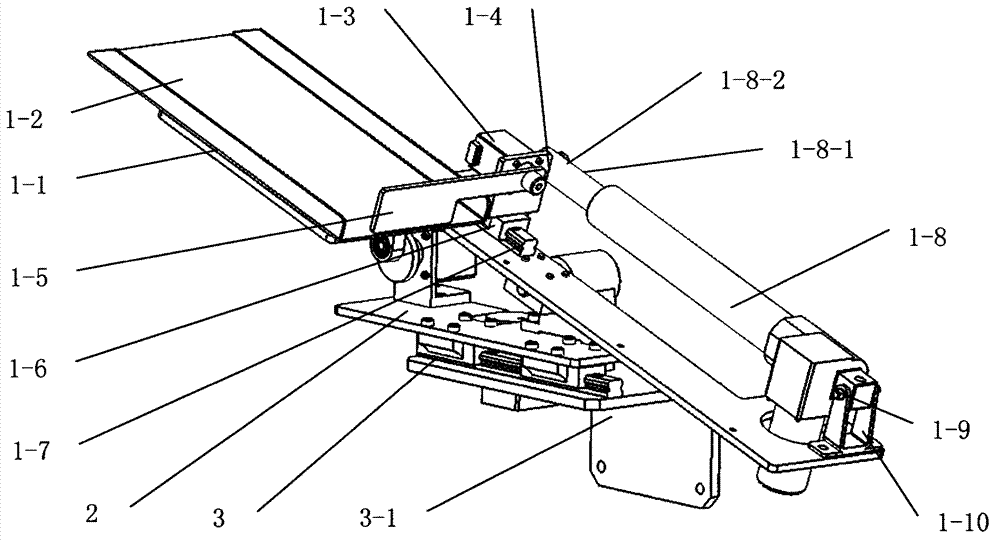

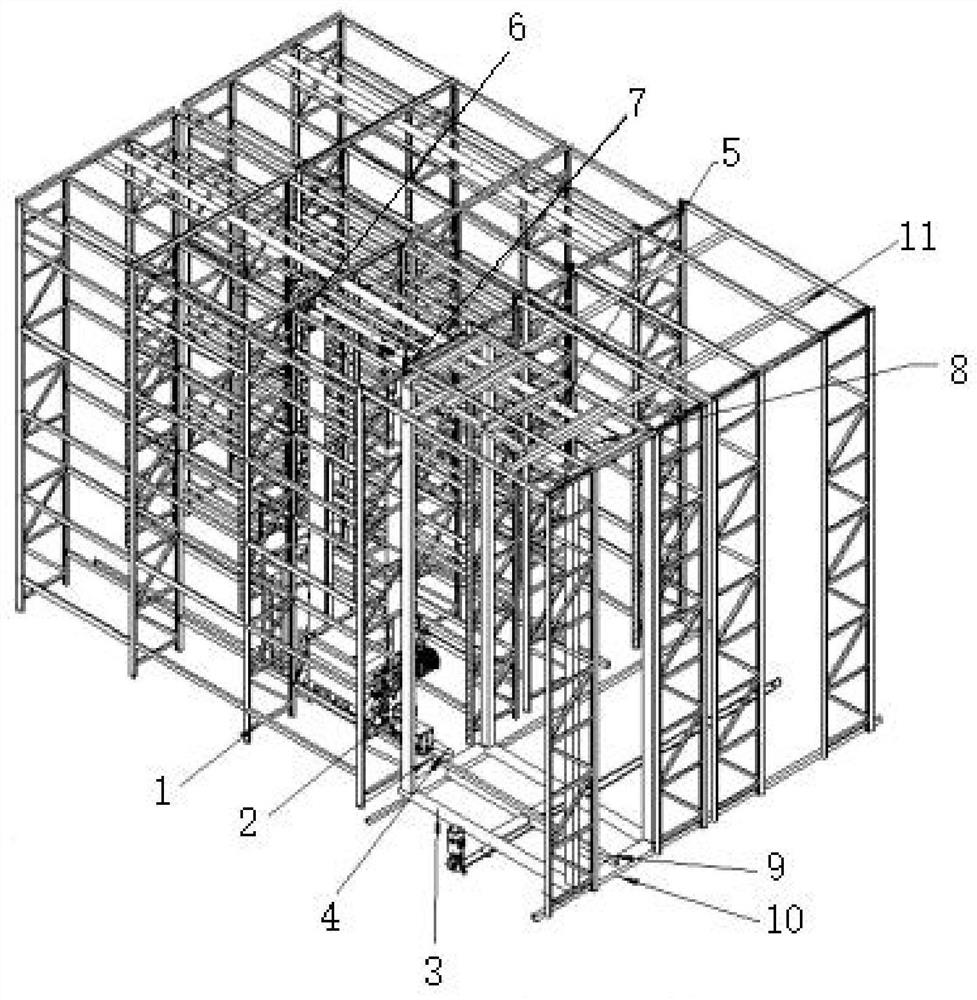

Novel transplanting type roadway stacker rail changing system

InactiveCN111776575AImprove efficiencyEasy constructionStorage devicesManufacturing cost reductionAgricultural engineering

Owner:安徽沃森智能科技有限责任公司

Part in-out warehouse conveying system

The invention belongs to the technical field of intelligent warehousing, and particularly relates to a part in-out warehouse conveying system. The part in-out warehouse conveying system comprises an in-out warehouse communicating frame, a large tray, supporting feet, an AGV shuttling between a station and the supporting feet, and a joist barrow for taking parts away from the supporting feet and transferring the parts to the large tray, wherein each supporting foot comprises a supporting leg and a supporting beam; a visual collecting system used for collecting the outlines of the parts or smalltrays when the AGV is located at the supporting feet is arranged above the supporting feet; a fork finger is arranged at the lower portion of the joist barrow; and the in-out warehouse communicatingframe is in butt joint with a certain layer frame of a goods shelf, and the in-out warehouse communicating frame and the layer frame are each additionally provided with an unpowered roller line. According to the part in-out warehouse conveying system, the parts of different specifications are conveyed to the supporting feet of the corresponding specifications through the AGV and accurately conveyed to the large tray through the joist barrow, the parts are stored on the multi-layer goods shelf through a stacking machine, and the occupied area for part storage is greatly reduced.

Owner:ZHEJIANG EMERGEN ROBOT TECH CO LTD

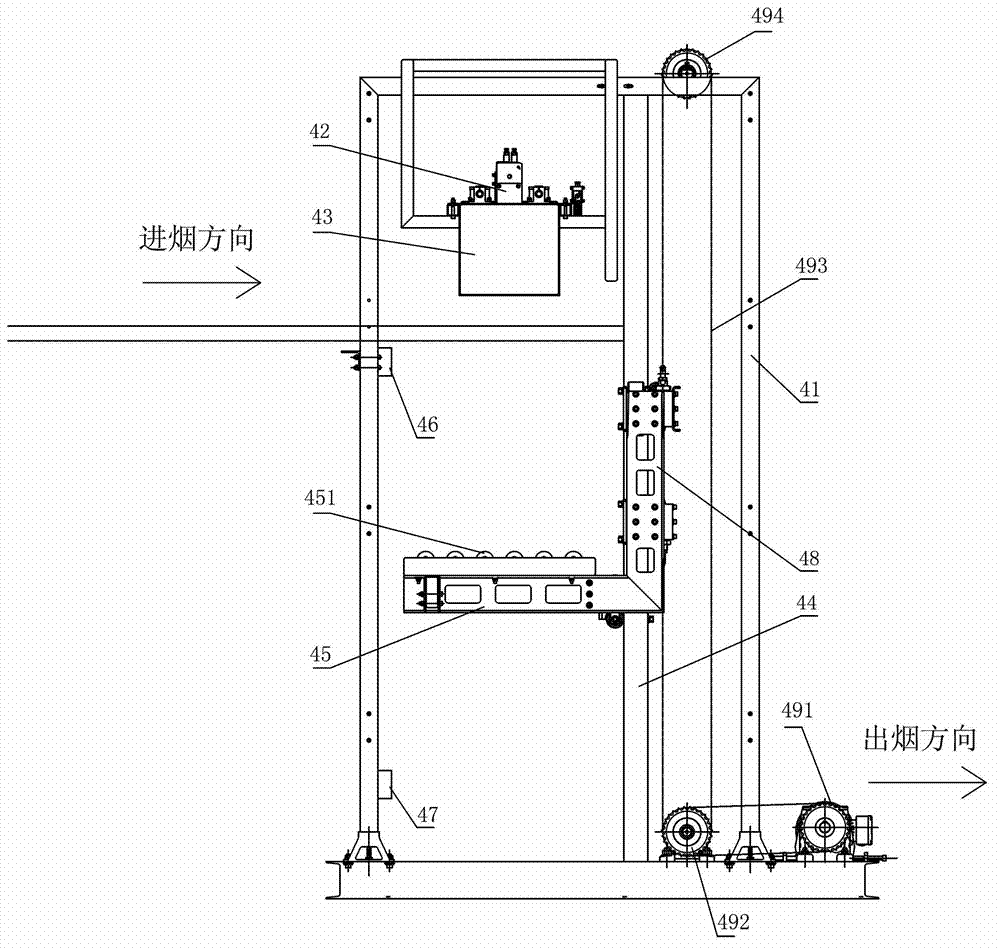

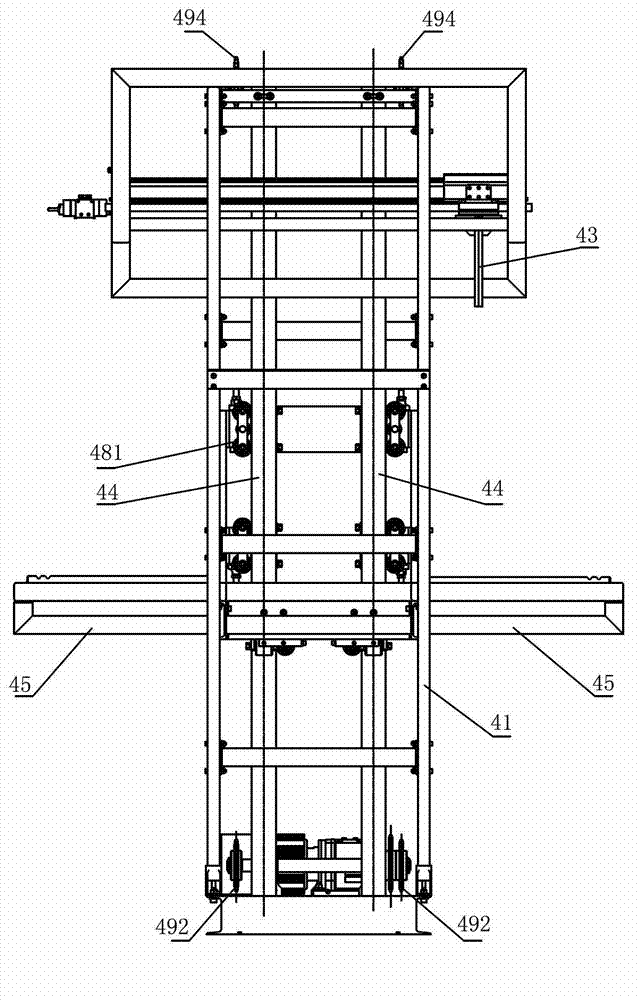

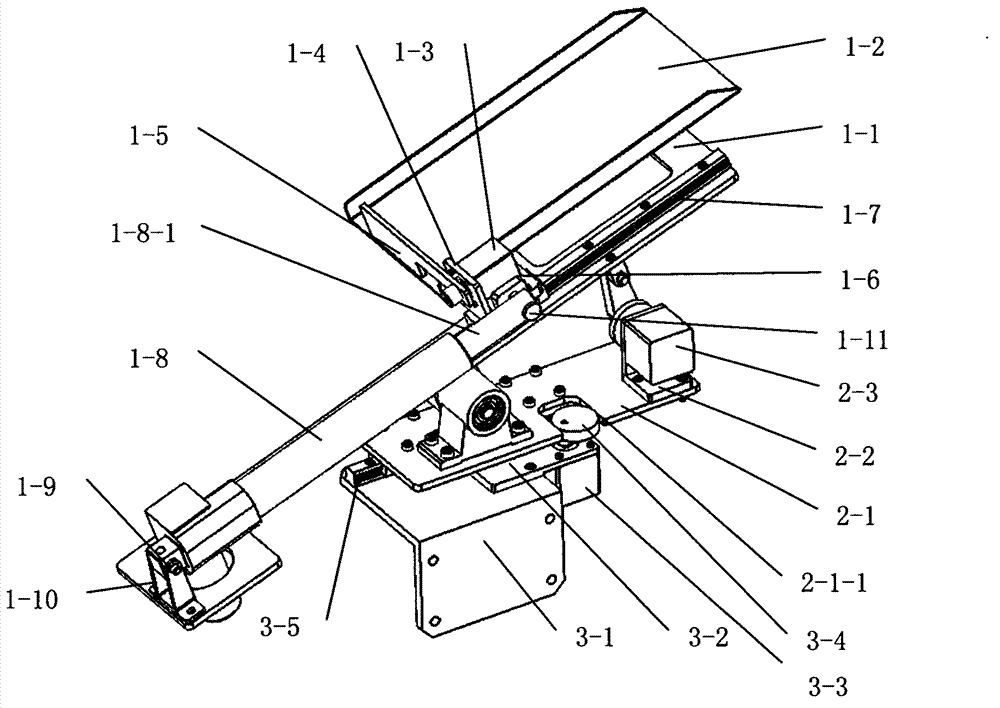

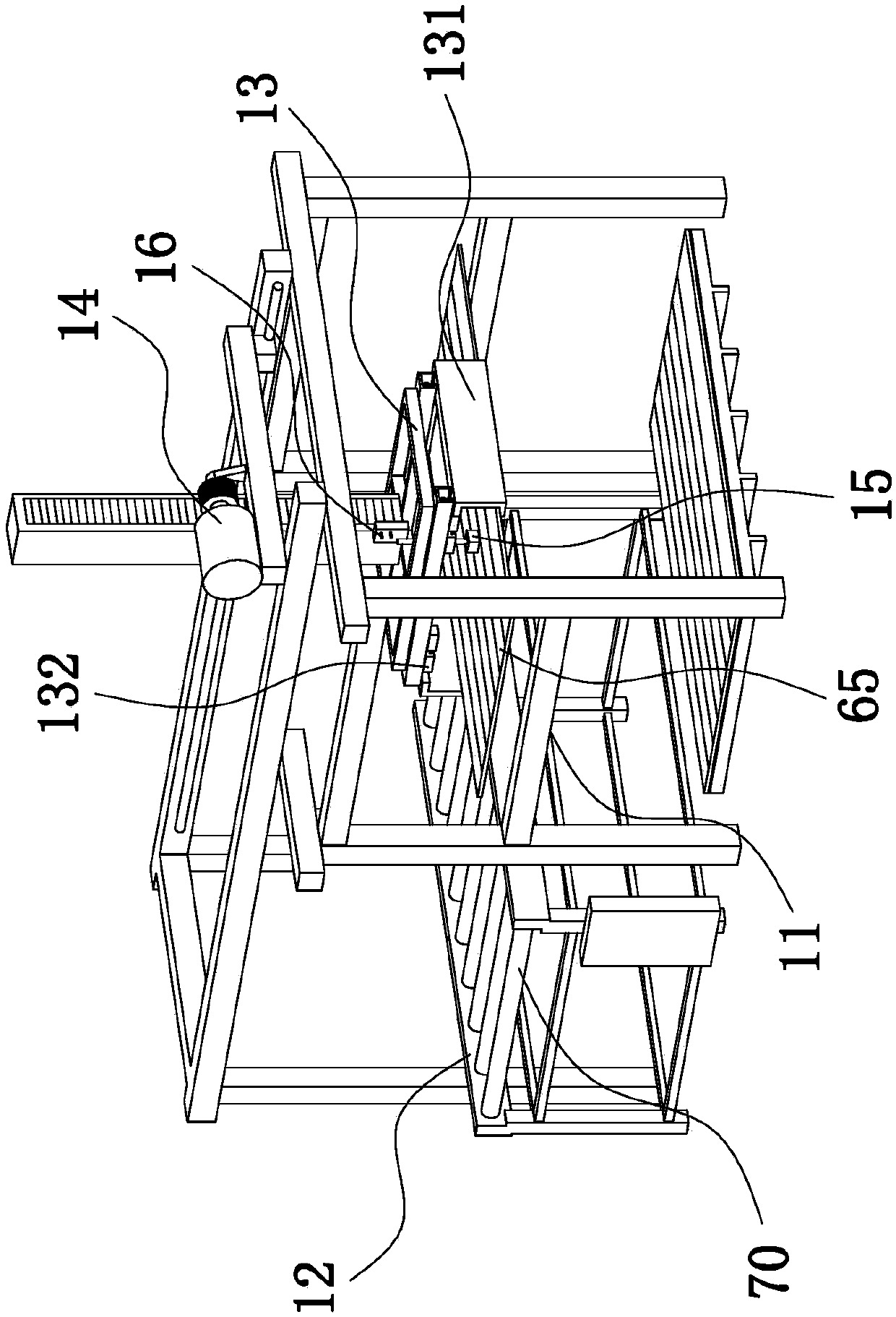

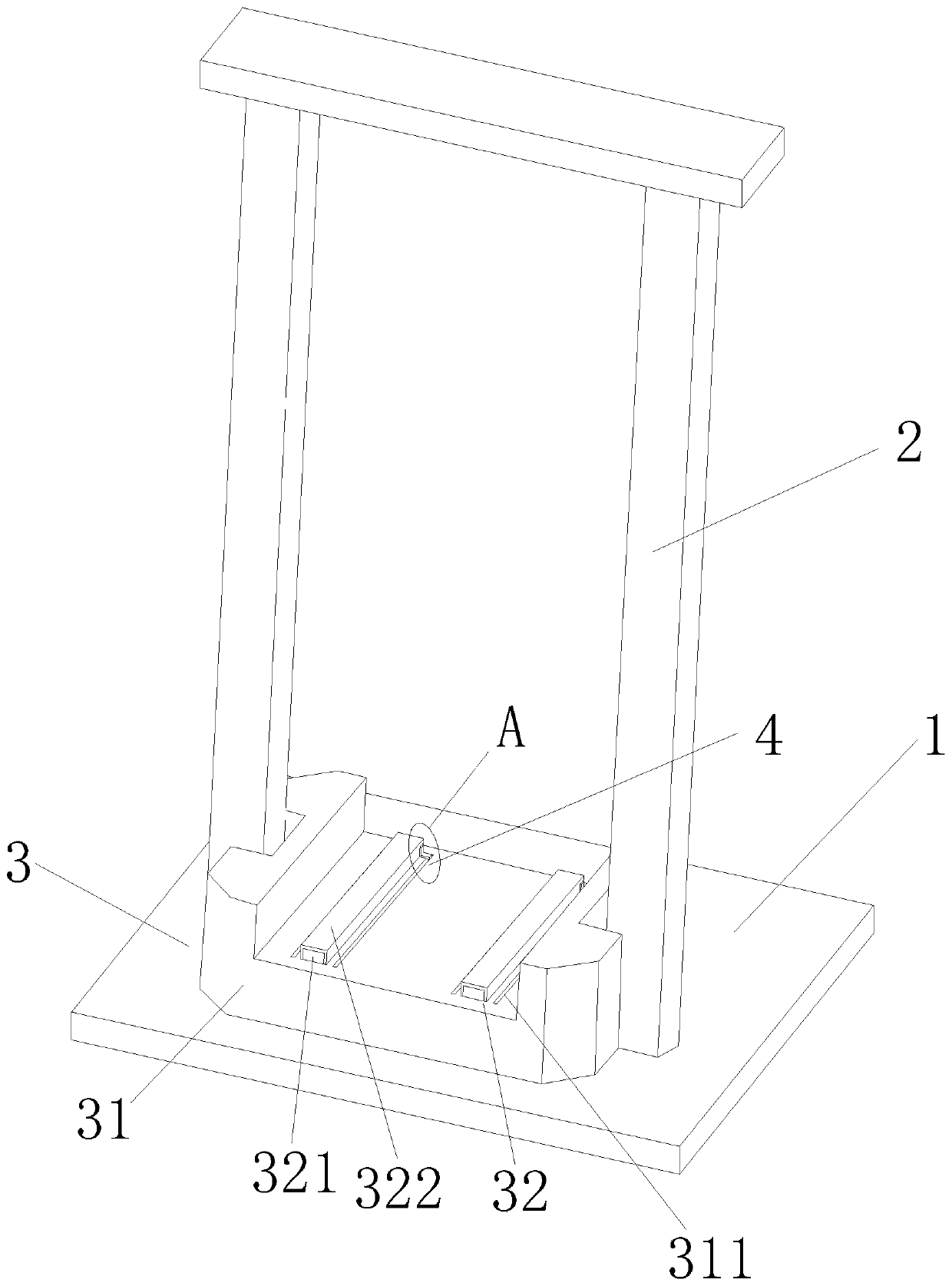

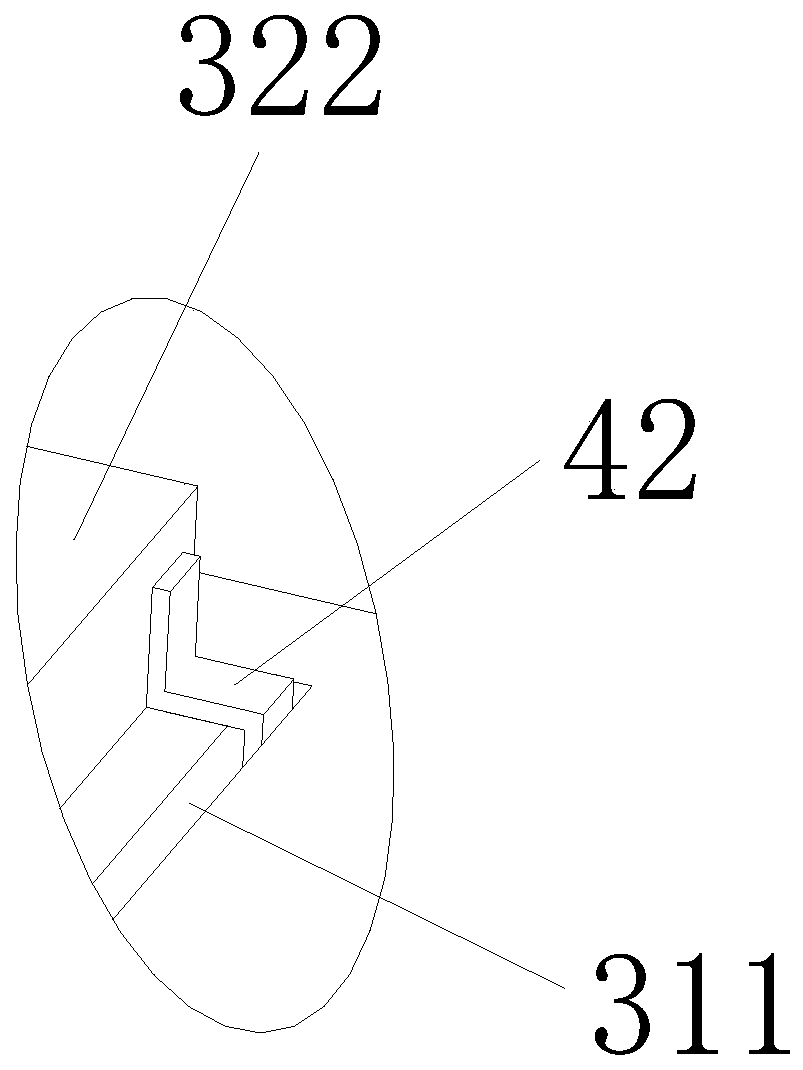

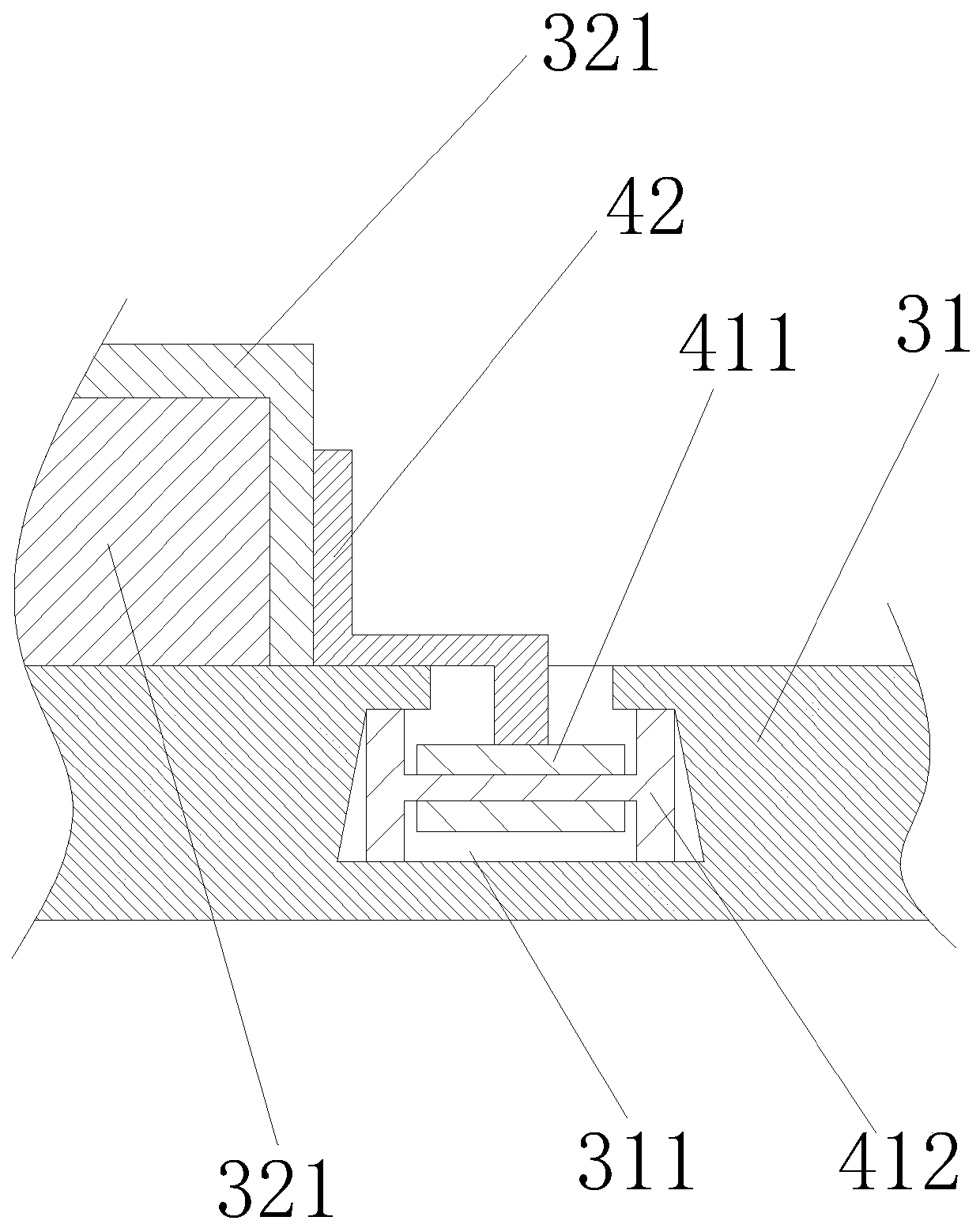

Stacker for warehousing logistics

InactiveCN109896470AGuaranteed successLessen the burden of gravityLifting devicesLogistics managementEngineering

Owner:安徽融易供应链管理有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap