Novel transplanting type roadway stacker rail changing system

A stacker and roadway technology, applied in the field of stackers, can solve the problems of high construction cost and cost, slow driving speed and low utilization rate of workshop, so as to reduce the maintenance cost in the later stage, reduce the manufacturing cost, and improve the usage. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

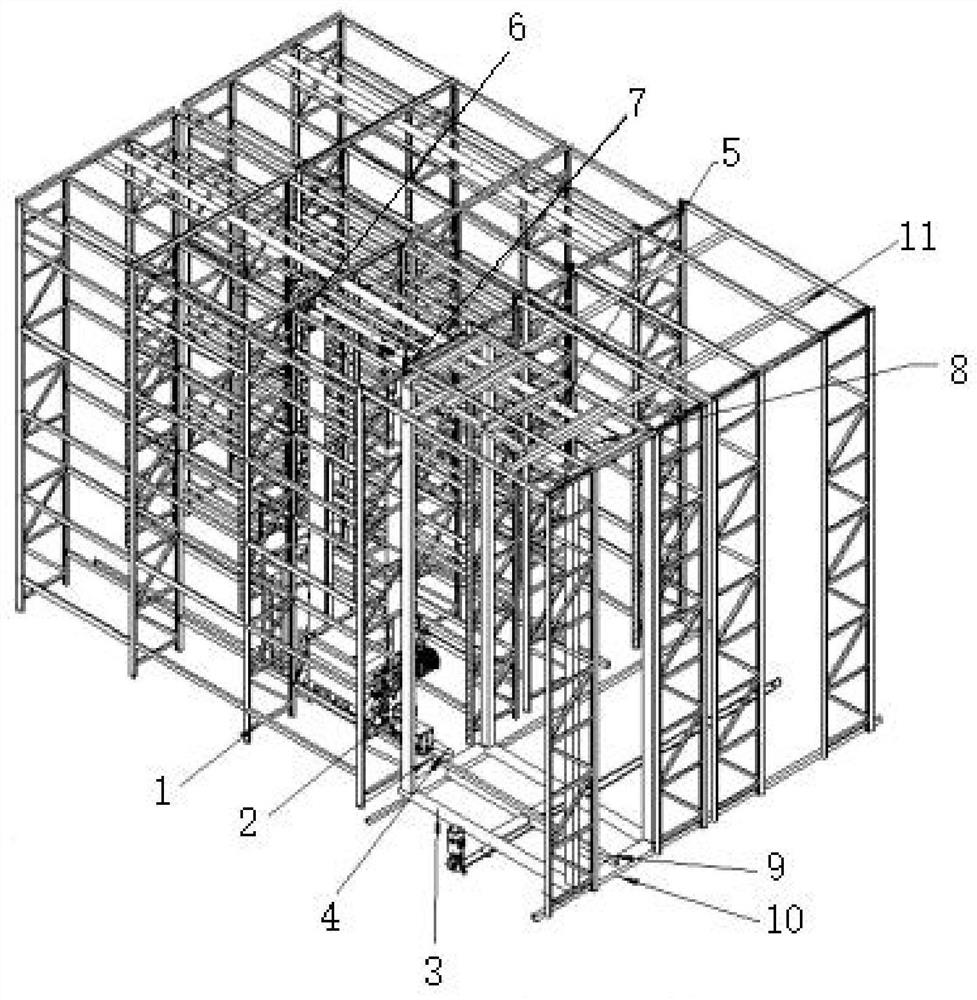

[0017] Such as figure 1 As shown, a new type of transplanting roadway stacker rail changing system, including a number of shelf lanes 1 adjacent to each other, a stacker 2 and a stacker transplanting car 3 arranged on any one of the shelf lanes 1 , the rails of stacker transplanting vehicles that are laterally distributed on the ends of several shelf lanes 1 on the same side, and the connecting tracks that are arranged between adjacent rack lanes 1, and the stacker transplanting vehicles 3 are arranged on the stacking machine on the track of the transplanting vehicle.

[0018] As a further improvement of the present invention, there are four rack lanes 1 arranged adjacent to each other. The stacker 2 is arranged in the third r

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap