Compound phosphate type positive material of lithium ionic cell and method for making same

A composite phosphate, lithium-ion battery technology, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problem of reducing the electrochemical and chemical stability of materials, low tap density of nano-lithium iron phosphate, and battery volumetric energy density. It can improve the electrochemical characteristics, increase the electrochemical performance, and facilitate large-scale production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

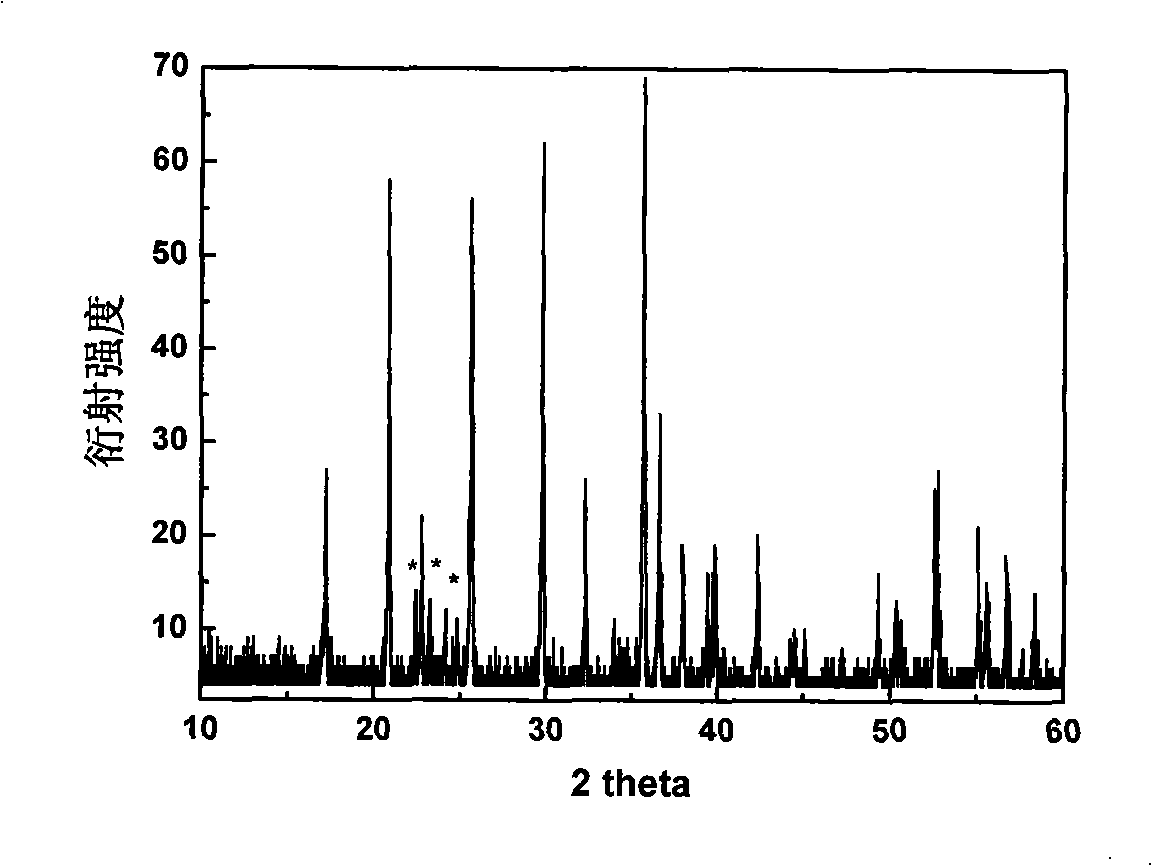

[0028] A lithium ion battery composite lithium iron phosphate 95% LiFePO 4 -5%Li 5 Fe 2 (PO 4 ) 3 The preparation method of the positive electrode material is to uniformly mix ferrous oxide, lithium oxide, and phosphorus pentoxide. The molar ratio of phosphorus, iron, and lithium is determined according to the chemical formula, and the temperature is raised to 650 ° C within 5 hours in nitrogen, and the heat preservation reaction is carried out for 8 hours. Cool to room temperature then, obtain lithium iron phosphate composite phase (phase XRD sees figure 2 );

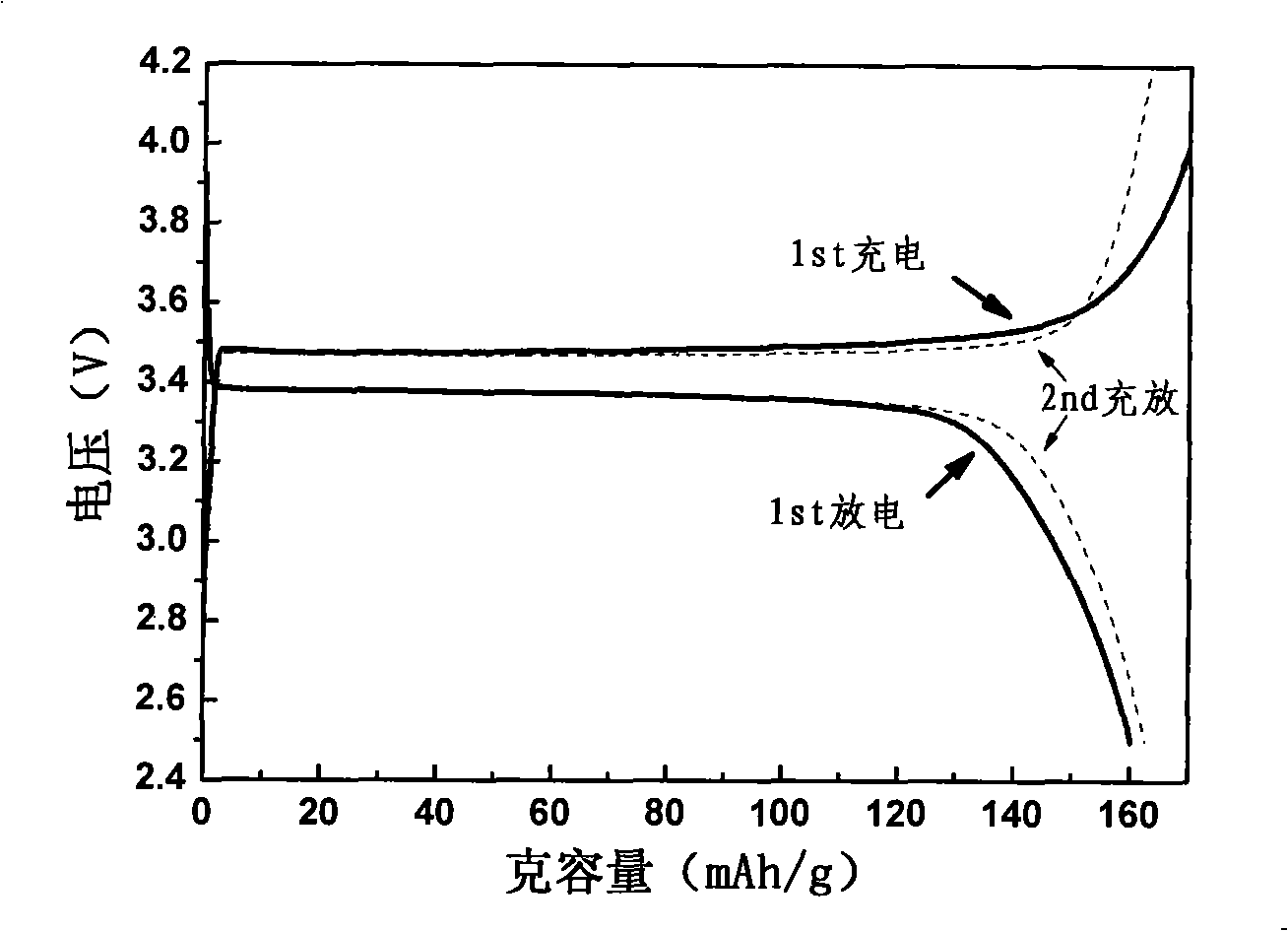

[0029] Add conductive agent acetylene black to the lithium iron phosphate composite phase, the amount of the conductive agent added is 5% of the weight of the lithium iron phosphate composite phase, and after sufficient ball milling, the output is the phosphate composite positive electrode material. 0.2C / 0.2C rate capacity is greater than 160mAh g -1 (see the initial secondary charge and discharge curve image 3

Embodiment 2

[0031] A lithium ion battery composite lithium iron phosphate 95% LiFePO 4 -5%LiTi 2 (PO 4 ) 3 The preparation method of the positive electrode material is to uniformly mix iron hydroxide, lithium carbonate, titanium dioxide, and ammonium dihydrogen phosphate, determine the molar ratio according to the chemical formula, and use 5% H 2 In the nitrogen atmosphere, the temperature was raised to 500°C within 3 hours, the heat preservation reaction was carried out for 10 hours, and then cooled to room temperature to obtain the phosphate composite phase;

[0032] Add conductive agent SiC in composite phase 1+x , the addition of the conductive agent is 3% of the weight of the composite positive electrode material, and after sufficient ball milling, the discharge is the phosphate composite positive electrode material. 1C rate charge and discharge specific capacity is 135mAh g -1 , The battery capacity does not decay after more than 100 cycles.

Embodiment 3

[0034] A Lithium-Ion Battery Composite Lithium Iron Phosphate 90% LiFePO 4 -10% Li 5 TiMn(PO 4 ) 3 The preparation method of the positive electrode material is to uniformly mix iron hydroxide, lithium carbonate, titanium dioxide, manganese dioxide, and ammonium dihydrogen phosphate, determine the molar ratio according to the chemical formula, and use 5% H 2 In nitrogen, the temperature was raised to 850°C within 10 hours, the temperature was kept for 4 hours, and then cooled to room temperature to obtain the phosphate composite phase;

[0035] Add conductive agent TiO in composite phase 2-x , the addition of the conductive agent is 2% of the weight of the composite positive electrode material, and after sufficient ball milling, the discharge is the phosphate composite positive electrode material. 1C rate charge and discharge specific capacity is 136mAh g -1 , The battery capacity does not decay after more than 100 cycles.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap