Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Barium chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barium chloride is the inorganic compound with the formula BaCl₂. It is one of the most common water-soluble salts of barium. Like most other barium salts, it is white, toxic, and imparts a yellow-green coloration to a flame. It is also hygroscopic, converting first to the dihydrate BaCl₂(H₂O)₂. It has limited use in the laboratory and industry.

Production method for nano barium sulfate particles

ActiveCN103159248ASmall particle sizeMaterial nanotechnologyCalcium/strontium/barium sulfatesBarium dichlorideAmmonium bromide

Owner:ZHUHAI SMOOTHWAY ELECTRONICS MATERIALS

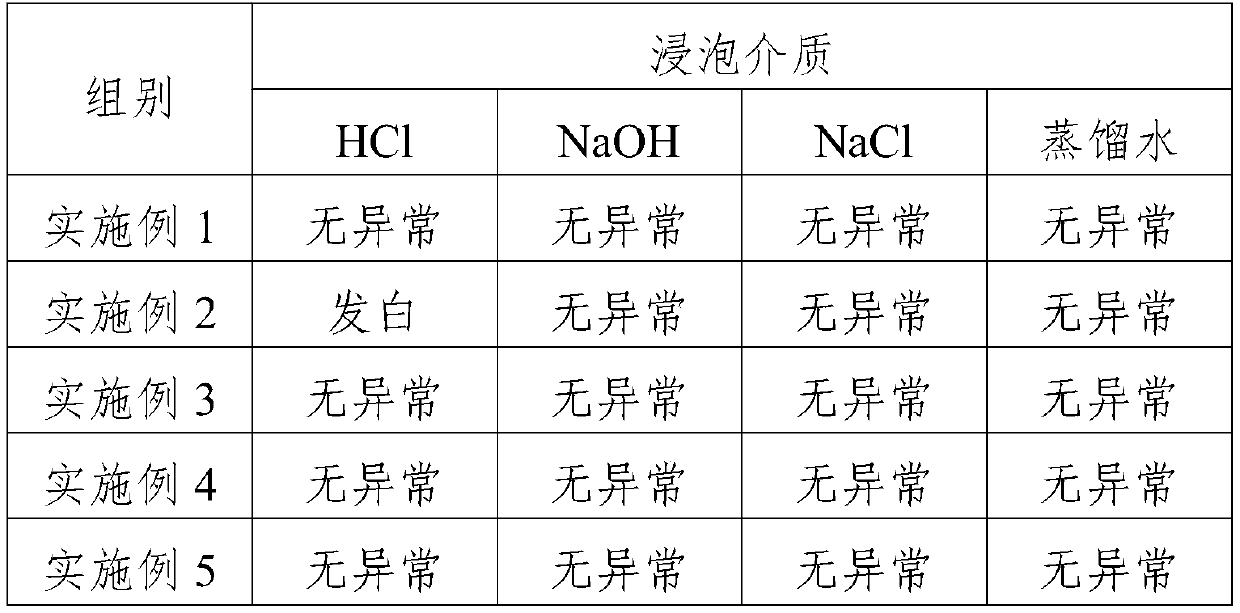

Full-inorganic interior and exterior wall coating and preparation method thereof

InactiveCN111393881AImprove corrosion resistanceStrong hardnessAlkali metal silicate coatingsAnti-corrosive paintsBarium solutionBarium dichloride

Owner:国鼎(苏州)材料科技有限公司

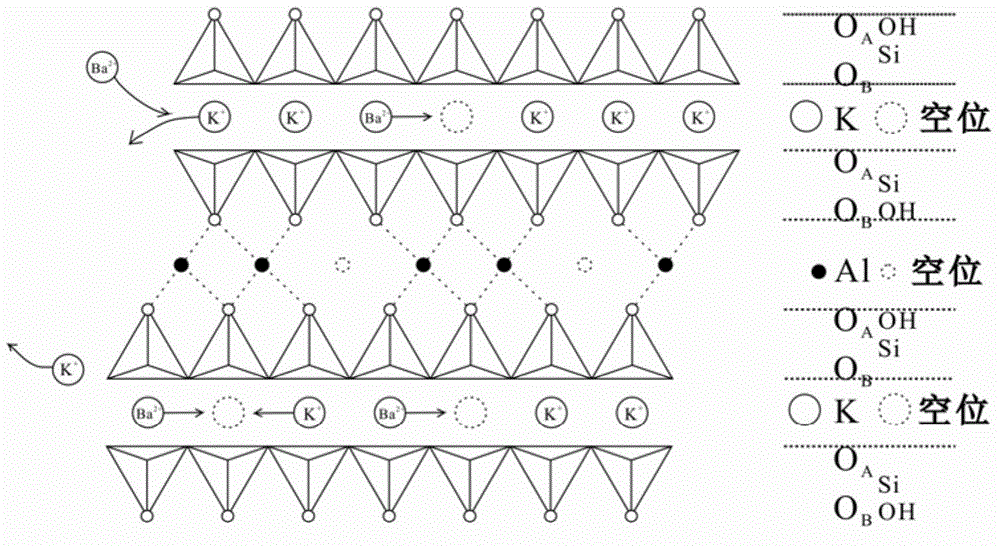

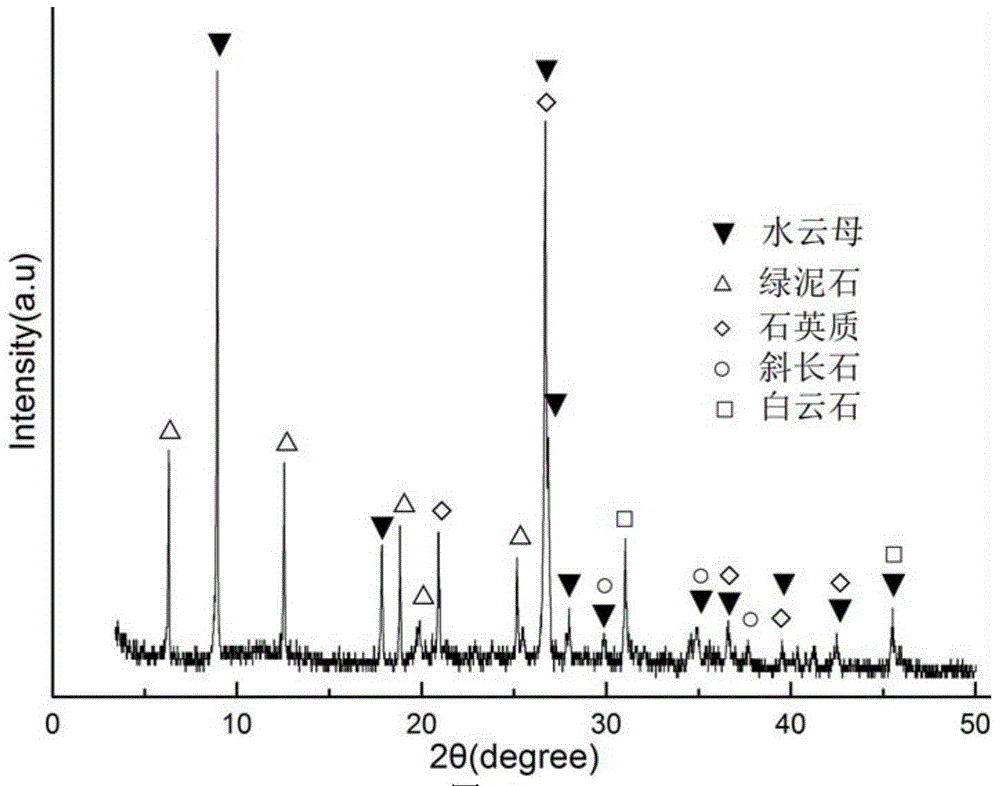

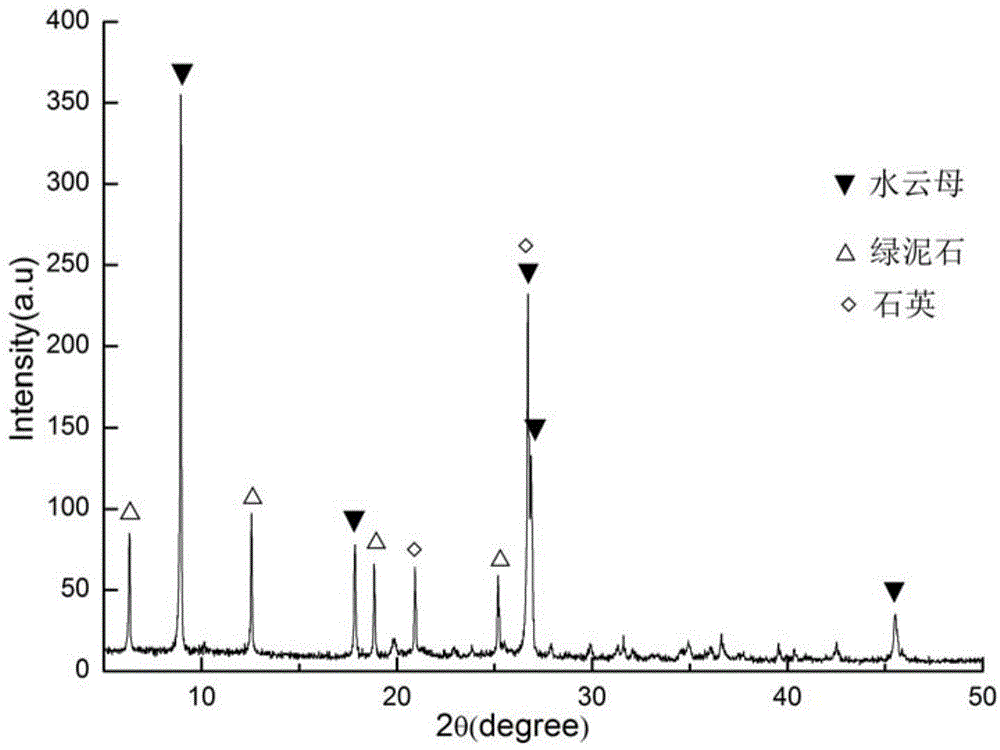

Method for extracting soluble potassium ions by adopting hydromica barium ion exchange method

InactiveCN103980009AMaintain layered structureHigh extraction ratePotassium fertilisersBarium dichloridePotassium ions

Owner:WUHAN INSTITUTE OF TECHNOLOGY

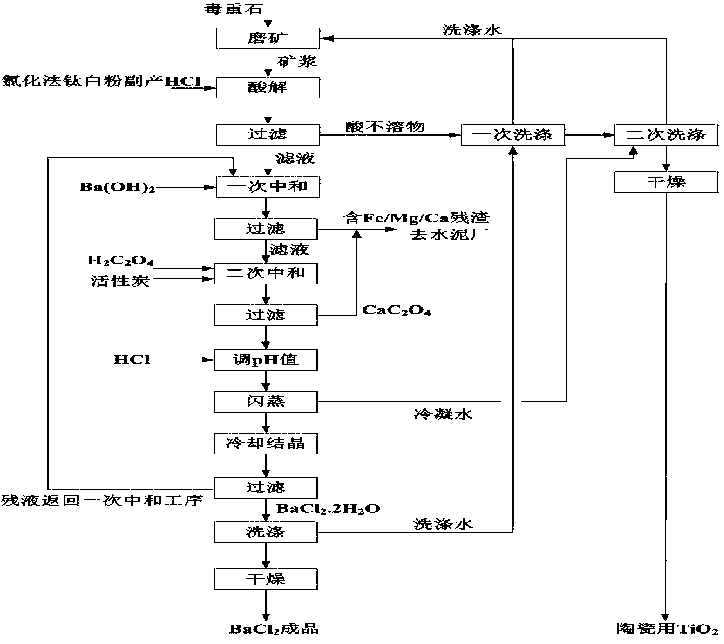

Method for co-producing barium chloride and ceramic titanium dioxide from chlorination process titanium dioxide byproduct hydrochloric acid

InactiveCN111591959AEfficient resource utilizationTake advantage ofCalcium/strontium/barium chloridesTitanium dioxideBarium dichlorideChloride salt

Owner:YIBIN UNIV

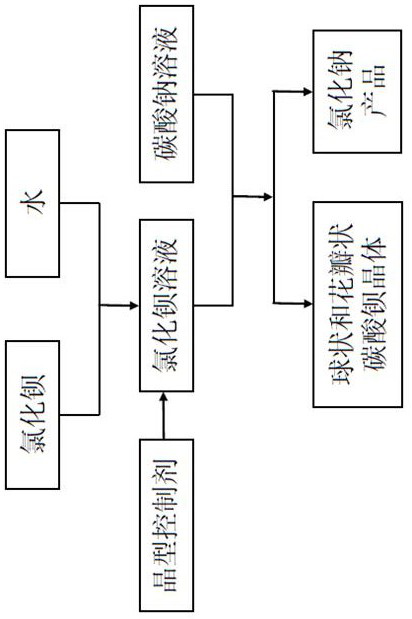

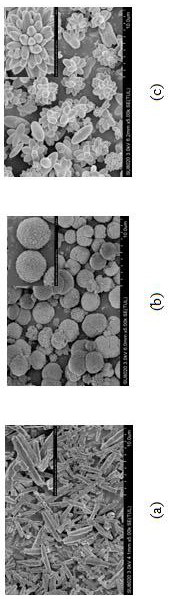

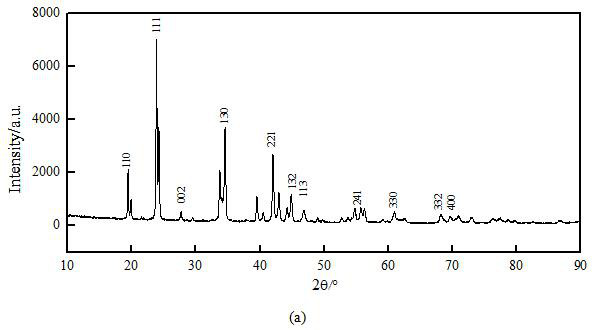

Preparation method of anhydrous barium carbonate crystals with special morphology

InactiveCN112194162ASolve the problem of high reaction temperatureHigh yieldBarium carbonatesBarium dichloridePhysical chemistry

Owner:NORTH CHINA INST OF SCI & TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap