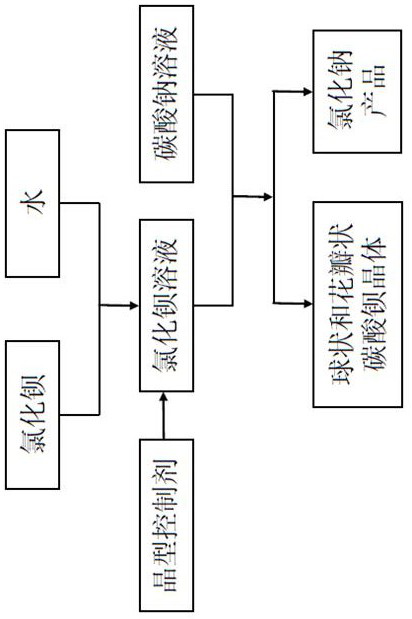

Preparation method of anhydrous barium carbonate crystals with special morphology

A barium carbonate and crystal technology is applied in the field of preparation of anhydrous barium carbonate crystals with special morphology (spherical and petal-shaped), and can solve the problem of difficult to obtain high-purity micro-nano products, difficult to control product morphology and size, complicated steps, etc. problems, to achieve the effect of increasing its own value, short response time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare a barium chloride solution with a concentration of 0.01mol / L; prepare a sodium carbonate solution with a concentration of 0.01mol / L;

[0034] Without adding a crystal form control agent, stir the magnesium chloride solution for 30 minutes to make a primary solution;

[0035] Put the primary solution in a beaker and put it into a heat-collecting constant temperature heating magnetic stirrer, heat it to 30°C, and under the stirring condition of 500r / min, add the same volume of sodium carbonate solution to the primary solution for hydrothermal reaction for 30min to obtain a white The reaction slurry of precipitation, wherein, the sodium carbonate solution add-on is the ratio metering of 1:1 by the barium ion mol ratio in carbonate ion and primary solution;

[0036] Filter the reaction slurry, take the solid phase, wash 5-7 times with deionized water, and filter until no chloride ions can be detected by using silver nitrate in the lotion to obtain the filtrate an

Embodiment 2

[0039] Method is with embodiment 1, and difference is:

[0040] Add the crystal form control agent to the barium chloride solution, stir for 30min, and make a primary solution; the crystal form control agent is citric acid, and its addition is 10% of the total weight of barium chloride dihydrate;

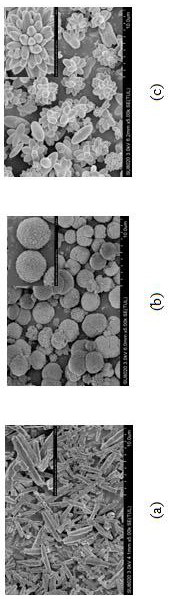

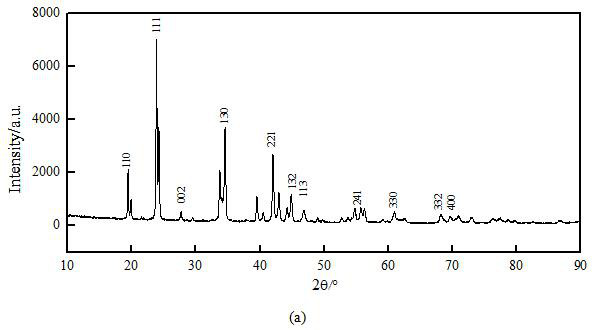

[0041] Dry the white precipitate in an electric blast drying oven at 80°C to produce rod-shaped anhydrous barium carbonate crystals. After testing, the purity of the rod-shaped anhydrous barium carbonate crystals is 98%, and the particle size is microns. SEM, XRD and FTIR photos Such as figure 2 Shown in (b), 3(b) and 4(b); The yield of rod-shaped anhydrous barium carbonate crystal is 98%.

Embodiment 3

[0043] Method is with embodiment 1, and difference is:

[0044] Add the crystal form control agent to the barium chloride solution and stir for 30 minutes to make a primary solution; the crystal form control agent is disodium ethylenediaminetetraacetic acid (EDTA-2Na), and its addition amount is 10% of the total weight of barium;

[0045] Dry the white precipitate in an electric blast drying oven at 80°C to produce rod-shaped anhydrous barium carbonate crystals. After testing, the purity of the rod-shaped anhydrous barium carbonate crystals is 98%, and the particle size is microns. SEM, XRD and FTIR photos Such as figure 2 Shown in (c), 3(c) and 4(c); The yield of rod-shaped anhydrous barium carbonate crystal is 98%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap