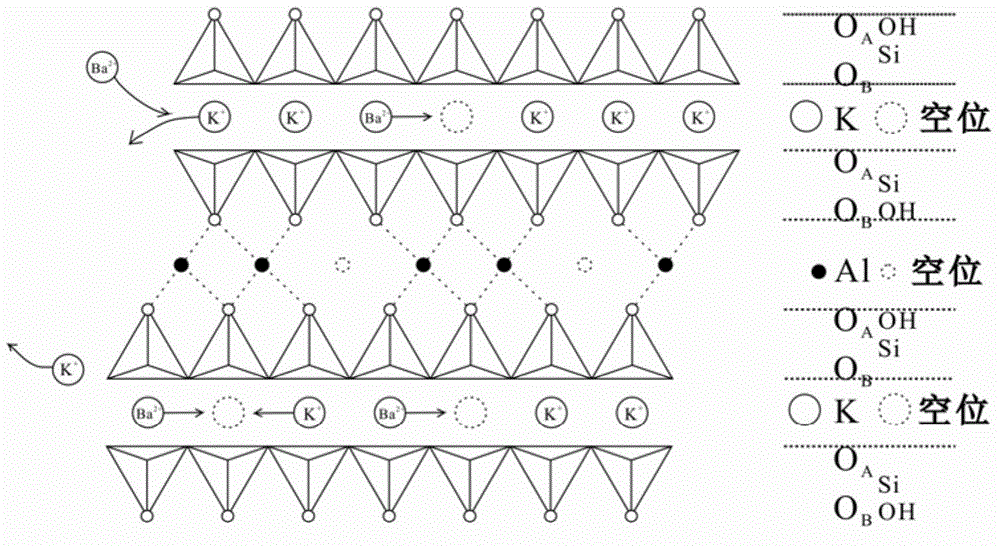

Method for extracting soluble potassium ions by adopting hydromica barium ion exchange method

A technology of hydromica and potassium ions, applied in the fields of chemistry and metallurgy, can solve the problems of environmental and cost control pressure, comprehensive utilization of unfavorable resources, difficulty in leaching potassium ions, etc., and achieves the effects of low cost, cost control, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

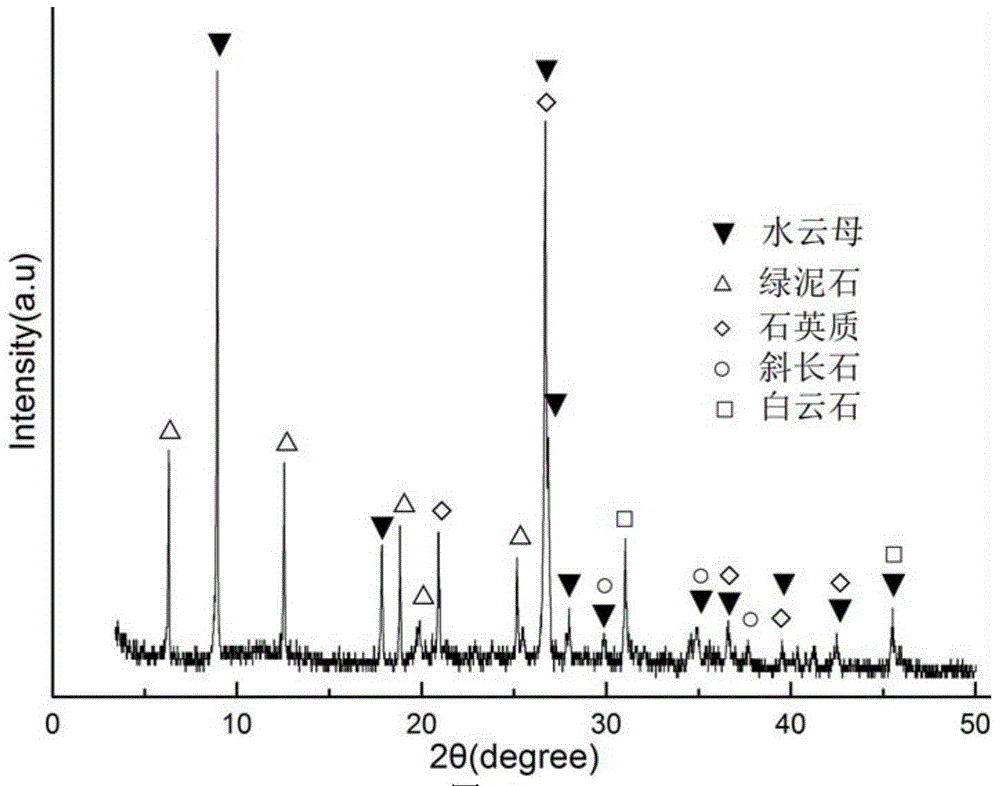

[0021] (1) Use a ball mill to pulverize the hydromica ore and pass it through a 200-mesh sieve, then carry out acid treatment, that is, soak it in hydrochloric acid with a concentration of 10wt% for 2 hours, take the sample and dry it, and use X-ray fluorescence (XRF) to analyze the obtained sample to measure the The potassium content w 0 (KO 2 ) is 3.01%;

[0022] (2) The water mica after the acid treatment is mixed with the aqueous solution of barium chloride with a concentration of 0.25mol / L. The mass volume ratio of the water mica and the aqueous solution of barium chloride is 1:20g / mL. The solution adjusts the pH value of the mixture to 2, places it in a constant temperature water bath at 30° C. and stirs it for 1 hour, collects the filtrate containing potassium ions by filtration, and measures the potassium content in the solid insoluble matter (potassium extraction residue). 1 It is 2.02%; the total depotassiation rate is 32.9%{w=(w 0 -w 1 ) / w 0}.

[0023] fig

Embodiment 2

[0025] (1) Use a ball mill to pulverize the hydromica ore and pass it through a 200-mesh sieve, then carry out acid treatment, that is, soak it in hydrochloric acid with a concentration of 10wt% for 2 hours, take the sample and dry it, and use X-ray fluorescence (XRF) to analyze the obtained sample to measure the The potassium content w 0 (KO 2 ) is 6.72%;

[0026] (2) The water mica after the acid treatment is mixed with the aqueous solution of barium chloride with a concentration of 1.00mol / L. The mass volume ratio of the water mica and the aqueous solution of barium chloride is 1:30g / mL. The solution adjusted the pH value of the mixture to 3, placed in a constant temperature water bath at 50°C and stirred for 3 hours, filtered to collect the filtrate containing potassium ions, and measured the potassium content in the solid insoluble matter w 1 It was 2.89%; the total potassium removal rate was 56.99% {w=(w0-w1) / w0}.

Embodiment 3

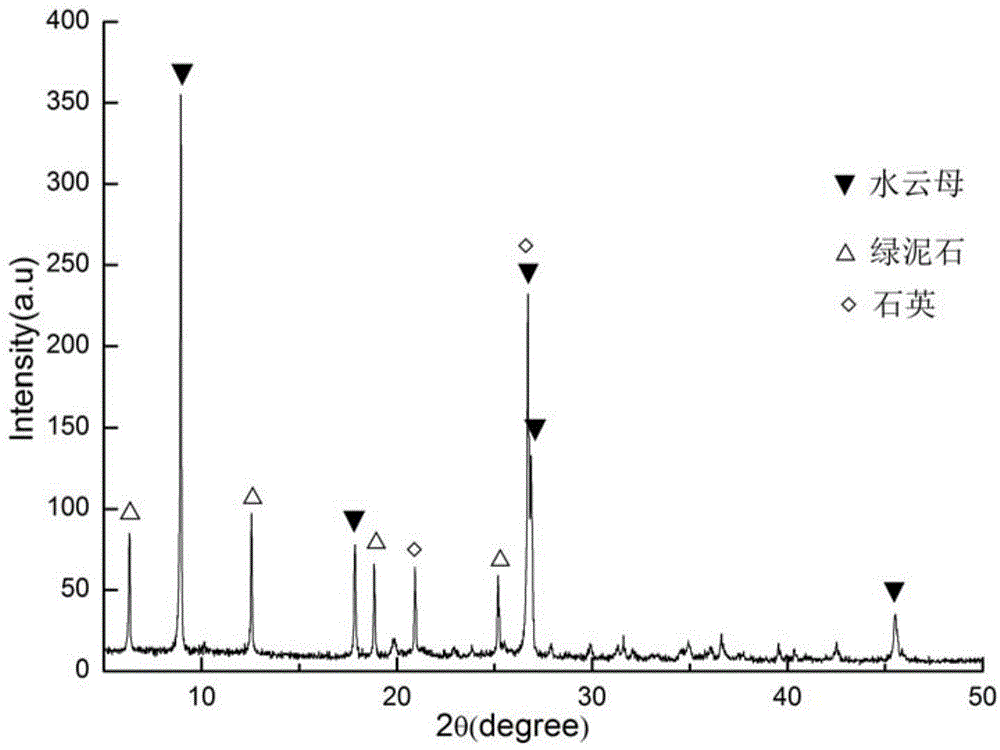

[0028] (1) Use a ball mill to pulverize the hydromica ore and pass it through a 200-mesh sieve, then carry out acid treatment, that is, soak it in hydrochloric acid with a concentration of 10wt% for 2 hours, take the sample and dry it, and analyze the obtained sample with X-ray fluorescence (XRF) to measure the The potassium content w 0 (KO 2 ) is 10.54%;

[0029] (2) The water mica after the acid treatment is mixed with the aqueous solution of barium chloride with a concentration of 1.75mol / L. The mass volume ratio of the water mica and the aqueous solution of barium chloride is 1:50g / mL. The solution adjusted the pH value of the mixture to 5, placed in a constant temperature water bath at 70°C and stirred for 5 hours, filtered to collect the filtrate containing potassium ions, and determined the potassium content in the solid insoluble matter w 1 It is 2.66%; the total depotassiation rate is 74.77%{w=(w 0 -w 1 ) / w 0}.

[0030] It can be seen from the above examples

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap