Carrying blank rolling method for producing steel plate of 6mm-thickness limit specification through medium-thickness plate

A technology of limit specification and steel plate, which is applied in the field of camel billet rolling for medium and heavy plate production of 6mm thick steel plate with limit specification, can solve the problem that the normal charging size of the heating furnace cannot be applied, and can overcome the problem that the normal charging size of the heating furnace cannot be applied. , the effect of avoiding rolling risks and hazards to equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The billet specifications and rolling target specifications of billet A and billet B are shown in Table 1:

[0020] Table 1:

[0021] billet

Specifications (mm)

Rolling target specification (mm)

Rolling condition

Top blank to be backed (A)

110×1520×2500

6.1×1800×46500

rolling success

Underside back material (B)

200×1450×3500

10×2600×34000

rolling success

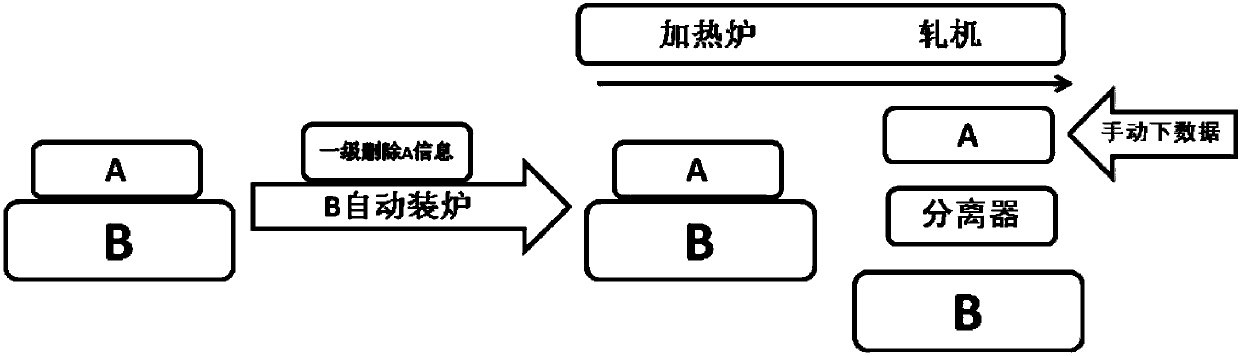

[0022] Billet B is a billet of conventional production specifications, which can be used for the normal billet size of the heating furnace; billet A is used for rolling 6mm thick limit specification steel plate, and its length specification is 2500mm, which cannot be used for the normal billet size of the heating furnace. Put the blank B as the back blank, place the blank A as the back blank on the top of the blank B, use the blank B to carry the blank A, and send it into the heating furnace for heating.

[0023] The sequence of the rolling plan is based on the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap