Roll gap adjusting and fixing device

A technology of fixing devices and adjusting devices, which is applied in the direction of metal rolling, metal rolling racks, manufacturing tools, etc., can solve the problems affecting the normal production order of wire rods, restricting the production rate of equipment, and adjusting nut breakage, etc. It is inconvenient to adjust the seam, reduce the probability of deformation and even fracture, and eliminate the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

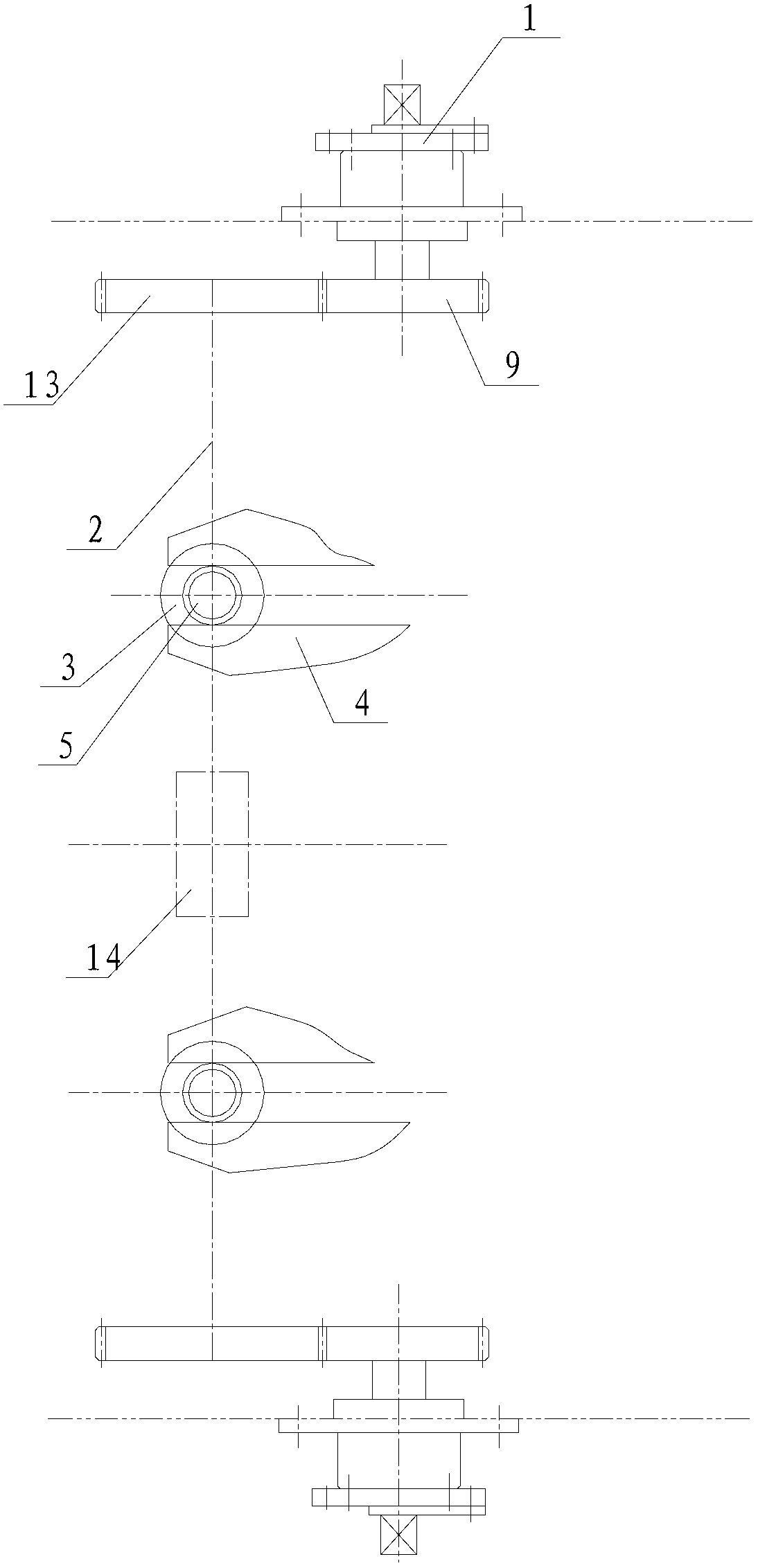

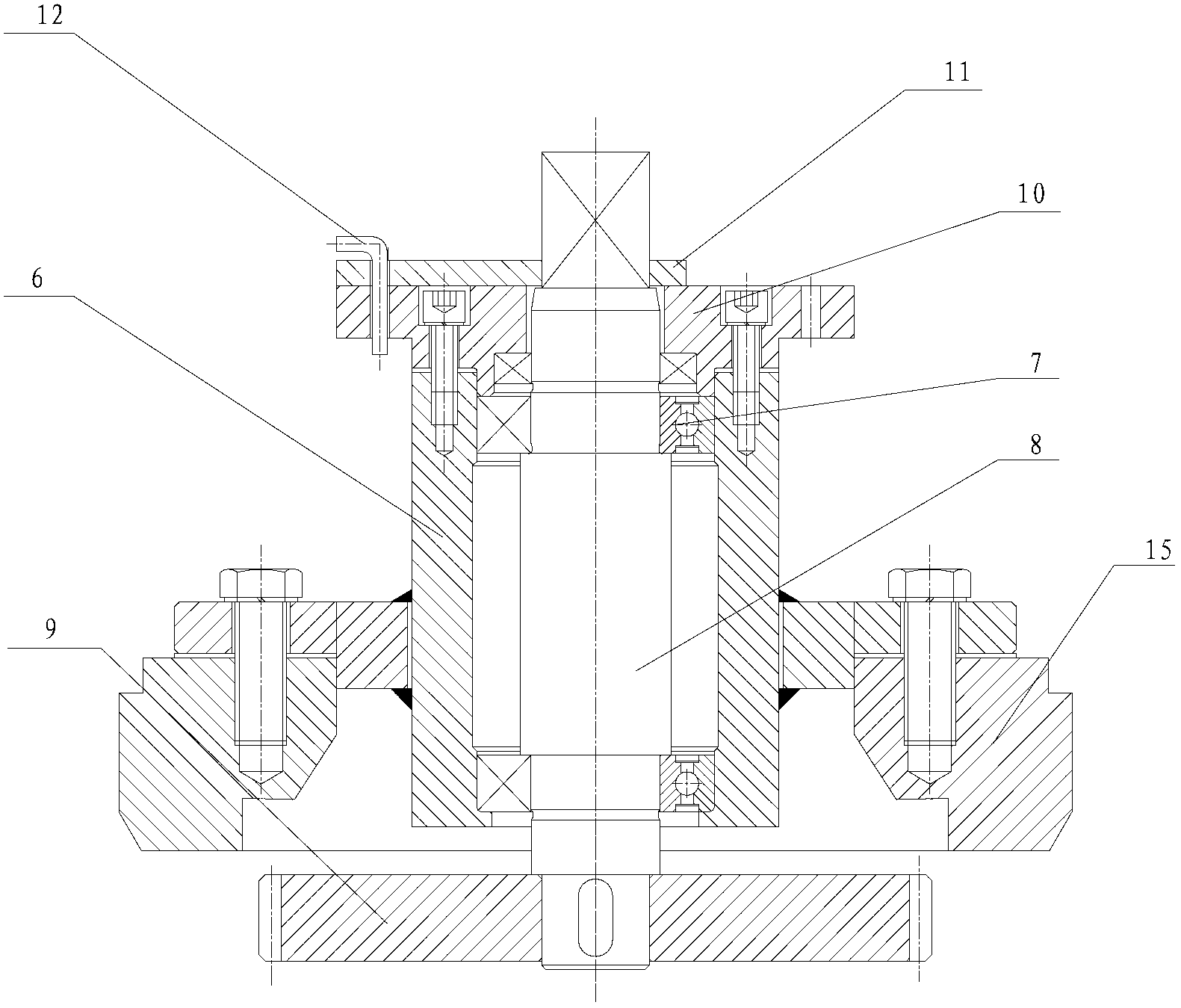

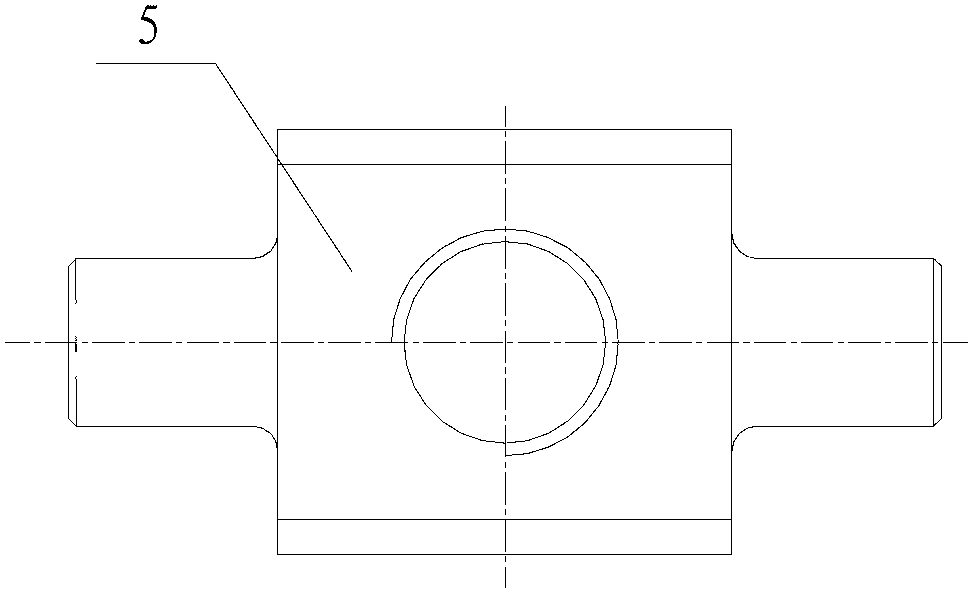

[0015] A roll gap adjustment and fixing device provided in this embodiment has a structure such as Figure 1 to Figure 4 As shown, it includes the adjustment device 1 installed on both sides of the cone box body 15, the adjustment devices on both sides are connected by the adjustment screw 2, and the adjustment screw 2 is also provided with a sleeve type installed by the adjustment nut 5. The pulley 3 is provided with an eccentric sleeve chute 4 on the sleeve type pulley 3, and the adjustment device 1 includes a flange bearing seat 6 installed on the cone box body, and an adjustment shaft is assembled in the flange bearing seat 6 through a bearing 7 8. The first adjustment gear 9 is installed on the lower end of the adjustment shaft 8, and the upper part of the flange bearing seat 6 is provided with a cover plate 10 with an indexing indicator hole to seal the bearing 7 in the flange bearing seat; the upper end of the adjustment shaft 8 is sleeved There is a lock washer 11, one en

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap