Wire rod, steel wire, and part

A wire rod and steel wire technology, applied in the field of wire rod, can solve the problems of inability to obtain cold forgeable mechanical parts, inability to obtain cold forgeability, poor cold forgeability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

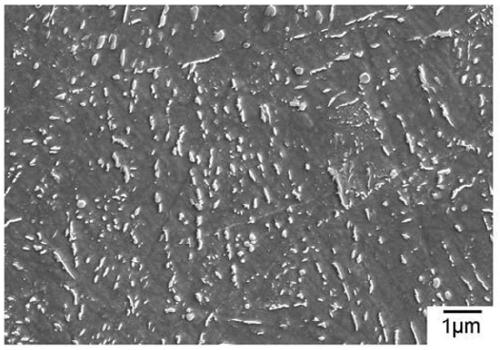

Image

Examples

Embodiment

[0100] Next, examples of the present invention will be described, but the conditions in the examples are examples of conditions adopted for confirming the practicability and effects of the present invention, and the present invention is not limited to the examples of conditions. The present invention can employ various conditions as long as the object of the present invention is achieved without departing from the gist of the present invention.

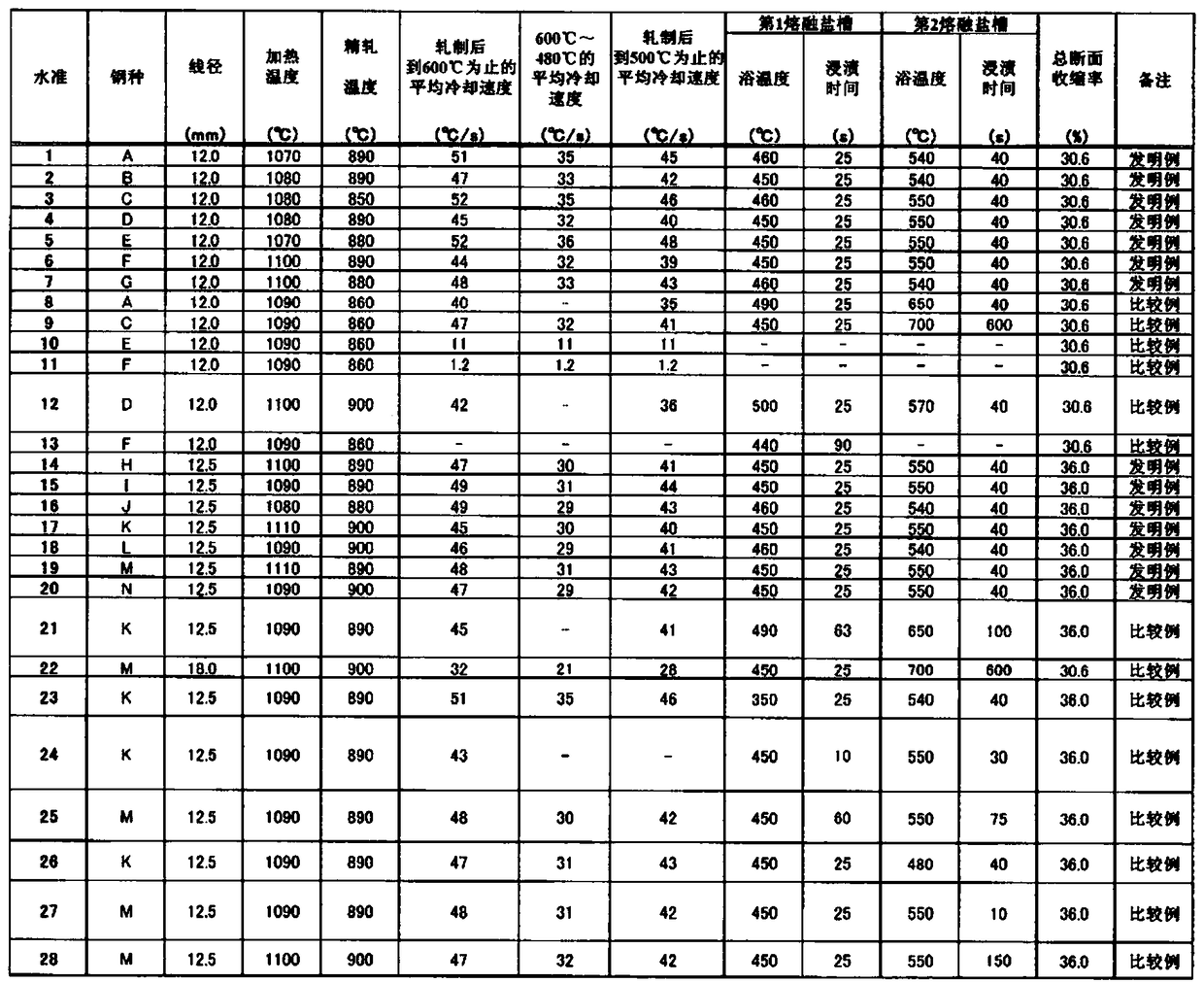

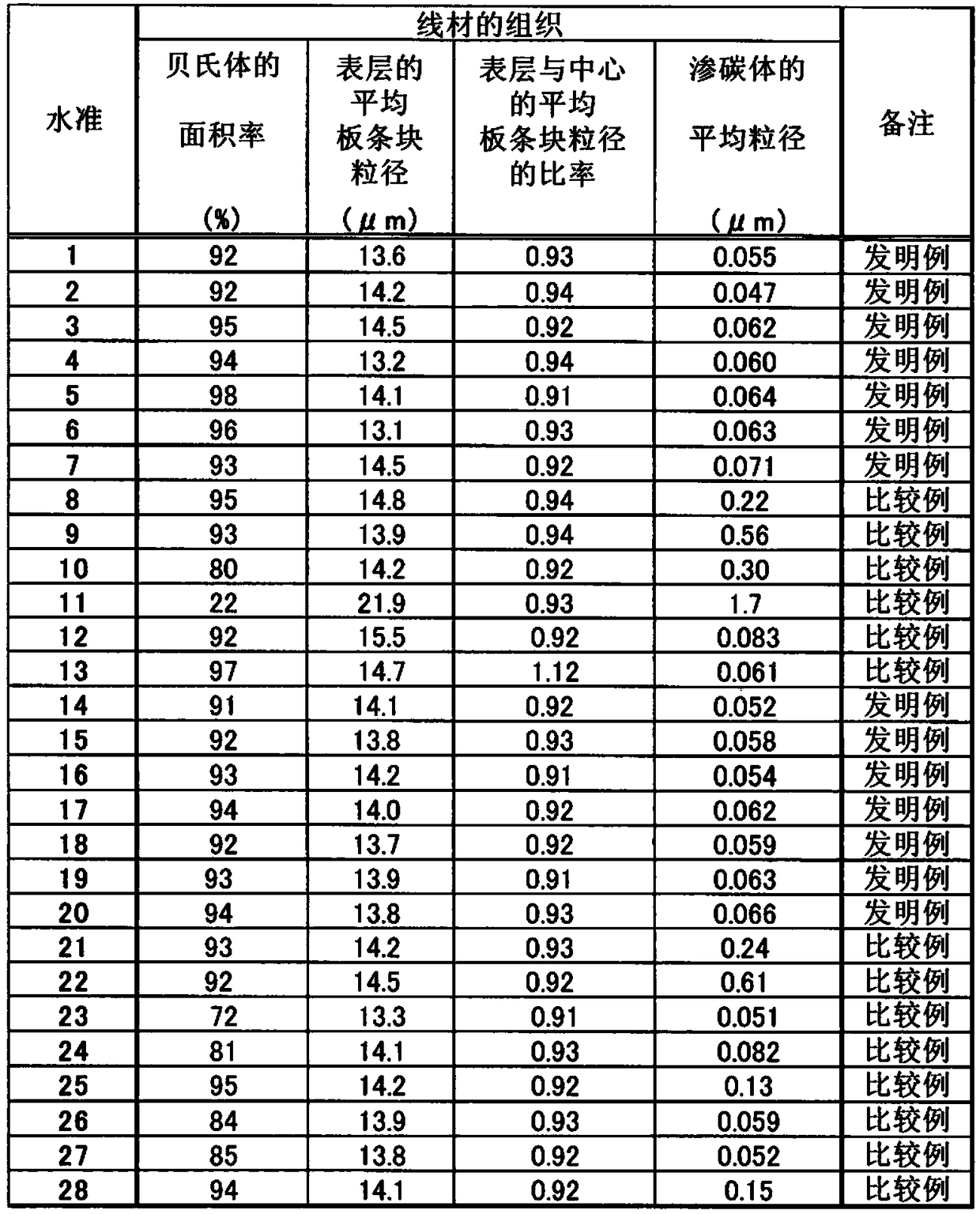

[0101] Using billets with the 14 compositions shown in Table 1, under the conditions of the 28 modes shown in Table 2, heating, hot rolling, constant temperature phase transformation treatment, and cooling were sequentially performed to manufacture wire rods (levels 1 to 28) ). Next, each wire rod was subjected to wire drawing at the reduction of area shown in Table 2 to manufacture steel wires (levels 1 to 28). Furthermore, using each steel wire, the sample whose height was 1.5 times the diameter was produced by machining, and componen

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap